High-precision mass flow controllers are the linchpin of data integrity in long-term catalyst studies. They ensure that reaction gas flow remains absolutely constant throughout extended testing periods, such as a 267-day lifespan test. By maintaining a stable Gas Hourly Space Velocity (GHSV), these controllers allow researchers to isolate catalyst performance from environmental variables, ensuring that conversion rate data accurately reflects the material's true capabilities.

In long-term experiments, consistency is the prerequisite for validity. A high-precision controller eliminates flow rate variance, ensuring that any observed changes in conversion rates are the result of catalyst degradation or radiation effects, rather than equipment fluctuation.

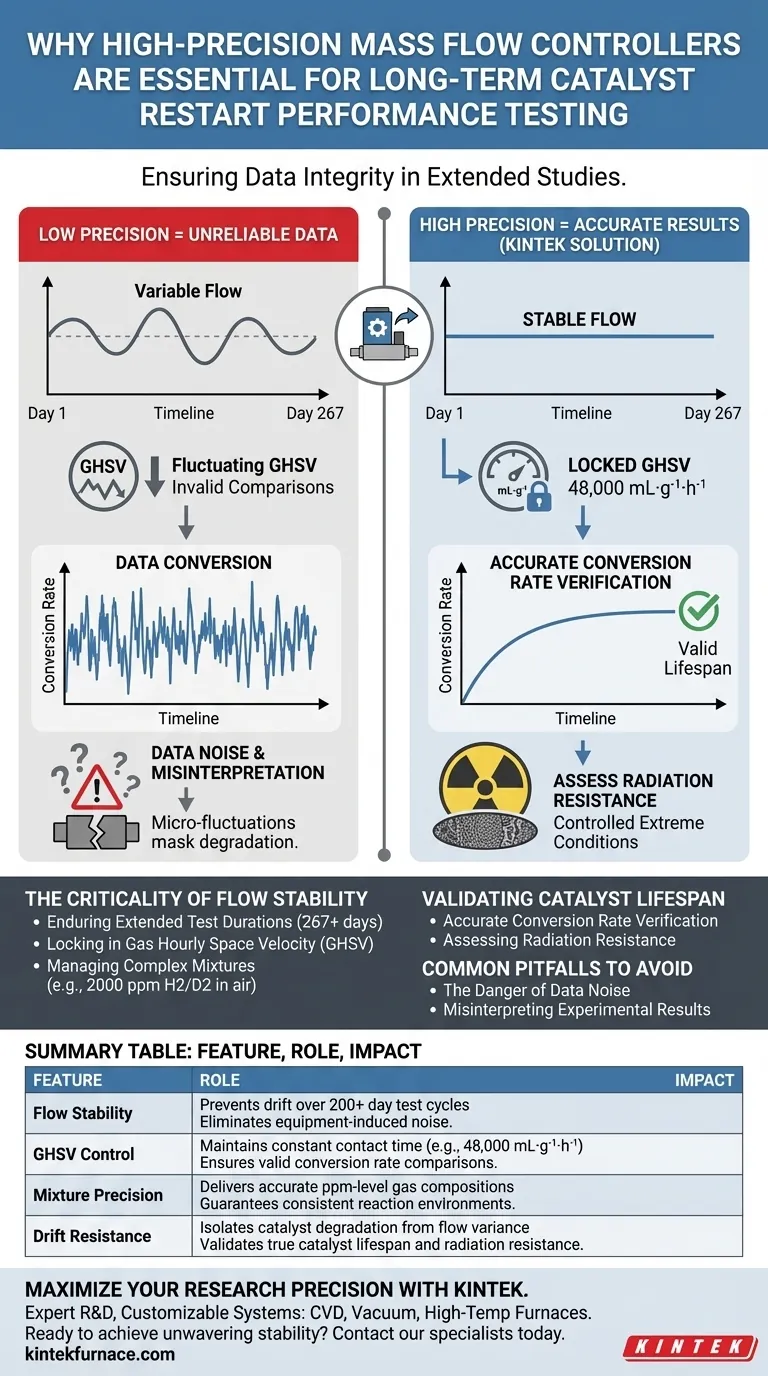

The Criticality of Flow Stability

Enduring Extended Test Durations

Long-term restart performance testing is a marathon, not a sprint. A typical test may run continuously for as long as 267 days.

During such extended periods, even minor drifts in gas flow can compound into significant data errors. High-precision controllers maintain uniformity from day one to the final day of testing.

Locking in Gas Hourly Space Velocity (GHSV)

The reliability of your data hinges on maintaining a specific GHSV. In high-stakes testing, this value often needs to be held at precise levels, such as 48,000 mL·g⁻¹·h⁻¹.

If the mass flow controller wavers, the GHSV fluctuates. This fluctuation alters the contact time between the gas and the catalyst, rendering conversion rate comparisons invalid.

Managing Complex Mixtures

These tests often involve specific gas mixtures, such as 2000 ppm H2/D2 in air.

Precise control is required not just for volume, but to ensure the mixture composition remains consistent as it is delivered to the reaction chamber.

Validating Catalyst Lifespan

Accurate Conversion Rate Verification

The primary goal of these tests is to verify the conversion rate of the catalyst over time.

To claim a specific lifespan or efficiency, the input variables must remain static. High-precision flow control provides the baseline stability required to prove that a catalyst meets its performance targets.

Assessing Radiation Resistance

Testing often pushes catalysts to their limits to verify radiation resistance under extreme operating conditions.

In these volatile environments, the equipment must be more robust than the variables being tested. A precise flow controller ensures that the "extreme conditions" remain controlled and measurable parameters rather than chaotic variables.

Common Pitfalls to Avoid

The Danger of Data Noise

A common error in long-term testing is underestimating the impact of micro-fluctuations.

If a controller lacks high precision, it introduces "noise" into the conversion rate data. This noise can mask subtle signs of catalyst degradation or, conversely, create false positives where the catalyst appears to fail simply because flow rates dropped.

Misinterpreting Experimental Results

Without strict flow control, it becomes impossible to distinguish between equipment behavior and catalyst behavior.

You risk attributing a drop in performance to the catalyst's inability to handle radiation or age, when it may simply be a result of inconsistent gas delivery.

Ensuring Success in Catalyst Verification

To ensure your long-term restart performance testing yields valid, publishable results, align your equipment choice with your specific experimental goals.

- If your primary focus is determining accurate lifespan: Prioritize a controller capable of maintaining drift-free operation over multi-month durations (e.g., 200+ days).

- If your primary focus is analyzing radiation resistance: Ensure the controller can maintain exact GHSV targets (like 48,000 mL·g⁻¹·h⁻¹) to rigorously stress-test the material under stable conditions.

Ultimate reliability in catalyst research is not achieved by the catalyst alone, but by the unwavering precision of the environment you create around it.

Summary Table:

| Feature | Role in Catalyst Testing | Impact on Data Quality |

|---|---|---|

| Flow Stability | Prevents drift over 200+ day test cycles | Eliminates equipment-induced noise |

| GHSV Control | Maintains constant contact time (e.g., 48,000 mL·g⁻¹·h⁻¹) | Ensures valid conversion rate comparisons |

| Mixture Precision | Delivers accurate ppm-level gas compositions | Guarantees consistent reaction environments |

| Drift Resistance | Isolates catalyst degradation from flow variance | Validates true catalyst lifespan and radiation resistance |

Maximize Your Research Precision with KINTEK

Don't let equipment fluctuations compromise your long-term catalyst validation. KINTEK provides high-precision laboratory solutions backed by expert R&D and manufacturing. Whether your research involves CVD systems, vacuum environments, or high-temperature furnaces, our customizable systems are designed to meet the most rigorous testing standards.

Ready to achieve unwavering stability in your lab? Contact our specialists today to discuss how our customizable heating and flow solutions can enhance your catalyst performance testing.

Visual Guide

References

- Guilin Wei, Xingwen Feng. Embedding Monodisperse LaO <i> <sub>x</sub> </i> Into Pt Nanoclusters for Ultra‐Stable and Efficient Hydrogen Isotope Oxidation. DOI: 10.1002/advs.202504224

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What factors are assessed during the evaluation for an Industrial Furnace project? Optimize Your Thermal Process

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- What is the purpose of adding phosphorus pentoxide (P2O5) as a desiccant? Ensure Deep Electrolyte Regeneration

- How does the ramp rate affect LDO properties? Master Rapid Thermal Control for 69% More Efficiency

- Why is the use of high-temperature furnace systems critical for delta-MnO2 development? Master Atomic Engineering

- What is the role of high-temperature calcination equipment in Waste Tire Charcoal preparation? Master WTC Pyrolysis

- What is the objective of placing TC4 titanium alloy parts on asbestos pads? Control Stress and Thermal Shock

- What is the function of placing a Nickel Mesh in a reactor? Maximizing Heat in Nickel-Hydrogen Systems