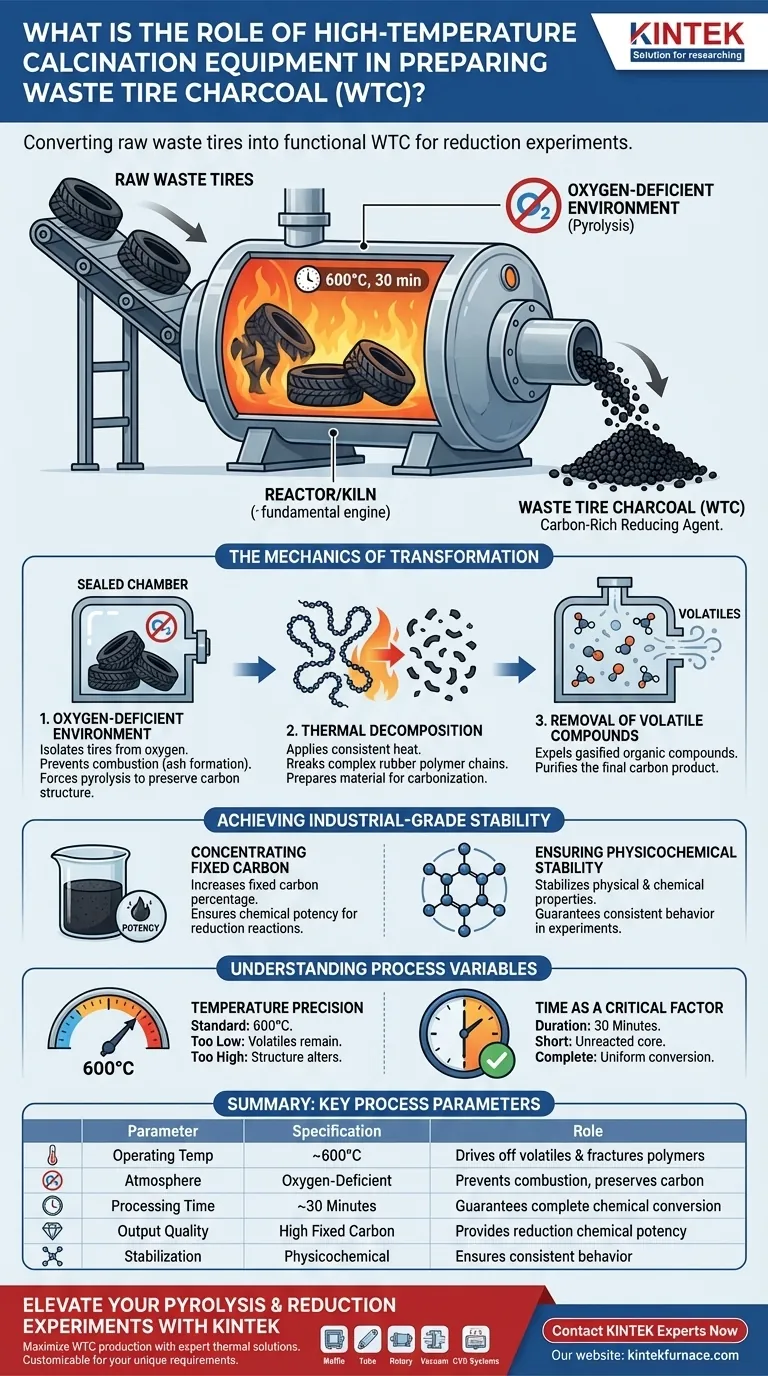

High-temperature calcination equipment serves as the fundamental engine for converting raw waste tires into functional Waste Tire Charcoal (WTC). By subjecting the material to approximately 600°C for 30 minutes in an oxygen-deficient environment, this equipment facilitates pyrolysis. Its primary role is to drive off volatile organic compounds and break down complex polymers, resulting in a carbon-rich material suitable for industrial reduction applications.

The equipment functions not merely as a heater, but as a reactor that chemically refines waste rubber into a stable, high-carbon reducing agent by strictly controlling thermal decomposition and atmospheric conditions.

The Mechanics of Transformation

To understand the equipment's role, one must look beyond simple heating. The machinery orchestrates a precise chemical restructuring of the source material.

Creating an Oxygen-Deficient Environment

The equipment is designed to isolate the waste tires from oxygen during the heating process.

This prevents the material from burning (combustion), which would result in useless ash. Instead, the lack of oxygen forces the material to undergo pyrolysis, preserving the carbon structure.

Thermal Decomposition of Polymers

Raw tires consist of complex rubber polymers that are chemically volatile.

The calcination equipment applies consistent heat to break these long polymer chains. This thermal stress fractures the complex bonds, preparing the material for its transition into charcoal.

Removal of Volatile Compounds

A critical function of the equipment is the separation of matter.

As the temperature reaches the target 600°C, volatile organic compounds gasify and are expelled from the solid mass. This purification step is essential for creating a clean final product.

Achieving Industrial-Grade Stability

The ultimate goal of using this equipment is to produce a reducing agent that performs predictably in chemical experiments.

Concentrating Fixed Carbon

By removing volatiles, the equipment significantly increases the percentage of fixed carbon in the remaining solid.

High fixed carbon content is the primary metric for a quality reducing agent. It ensures the charcoal has the chemical potency required for reduction reactions.

Ensuring Physicochemical Stability

Raw rubber is unstable and unsuitable for precise chemical reduction.

The calcination process stabilizes the physical and chemical properties of the WTC. This ensures that the charcoal behaves consistently when used as an industrial-grade agent.

Understanding the Process Variables

While the equipment is powerful, the process relies on strict adherence to operational parameters. Failing to maintain these variables compromises the quality of the WTC.

The Importance of Temperature Precision

The standard operating temperature is typically 600°C.

If the temperature is too low, volatile compounds may remain, diluting the carbon content. Conversely, excessive temperatures could alter the structural integrity of the charcoal unnecessarily.

Time as a Critical Factor

The process requires a specific duration, typically 30 minutes, to achieve complete conversion.

Cutting this time short risks leaving unreacted polymers in the core of the material. This results in an inconsistent product that lacks the necessary physicochemical stability.

Making the Right Choice for Your Goal

When configuring your calcination process for reduction experiments, align your equipment settings with your specific experimental requirements.

- If your primary focus is maximizing reactivity: Ensure your equipment maintains the target temperature of 600°C without fluctuation to guarantee high fixed carbon content.

- If your primary focus is material purity: Verify that the equipment maintains a strict oxygen-deficient seal to prevent ash formation and ensure the complete removal of volatiles.

Successful WTC preparation relies on using the equipment not just to burn waste, but to precisely refine it into a stable chemical tool.

Summary Table:

| Process Parameter | Specification/Requirement | Role in WTC Preparation |

|---|---|---|

| Operating Temp | ~600°C | Drives off volatiles and fractures polymer chains |

| Atmosphere | Oxygen-Deficient | Prevents combustion/ash and ensures carbon preservation |

| Processing Time | ~30 Minutes | Guarantees complete chemical conversion and stability |

| Output Quality | High Fixed Carbon | Provides the chemical potency needed for reduction |

| Stabilization | Physicochemical | Ensures consistent behavior in industrial experiments |

Elevate Your Pyrolysis and Reduction Experiments with KINTEK

Maximize the potential of your Waste Tire Charcoal (WTC) production with industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are refining waste rubber or developing advanced carbon materials, our high-temp lab furnaces are fully customizable to meet your unique temperature and atmospheric requirements.

Achieve industrial-grade stability and superior carbon purity today.

Visual Guide

References

- Menglan Zeng, Fawei Lin. Application of Waste Tire Carbon for Iron-Containing Dust Reduction in Industrial Processes. DOI: 10.3390/app15126504

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the core process advantages of using a microwave reactor? Maximize Speed & Efficiency in Lab Characterization

- What is the function of a rotary high-pressure autoclave in the synthesis of SSZ-13 zeolites? | Enhance Crystallinity

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization

- What specific information does SEM provide for LFP synthesis? Master Battery-Grade Quality Control

- What is the purpose of performing a final annealing treatment? Optimize Your Heterojunction Device Performance

- What is the primary function of a vacuum drying oven? Key to Composite Anode Slurry Preparation

- What role does fluorination process equipment play in the pretreatment of LiF-BeF2 salts? Ensure High-Purity Substrates

- Why is argon particularly attractive for industrial applications? Unlock Cost-Effective Purity and Stability