Scanning electron microscopy (SEM) provides critical visual validation of the physical structure and quality of lithium iron phosphate (LFP) synthesized via high-temperature methods. Specifically, it reveals the particle size distribution and morphological characteristics, allowing you to confirm if the reaction successfully produced polyhedral particles with distinct edges.

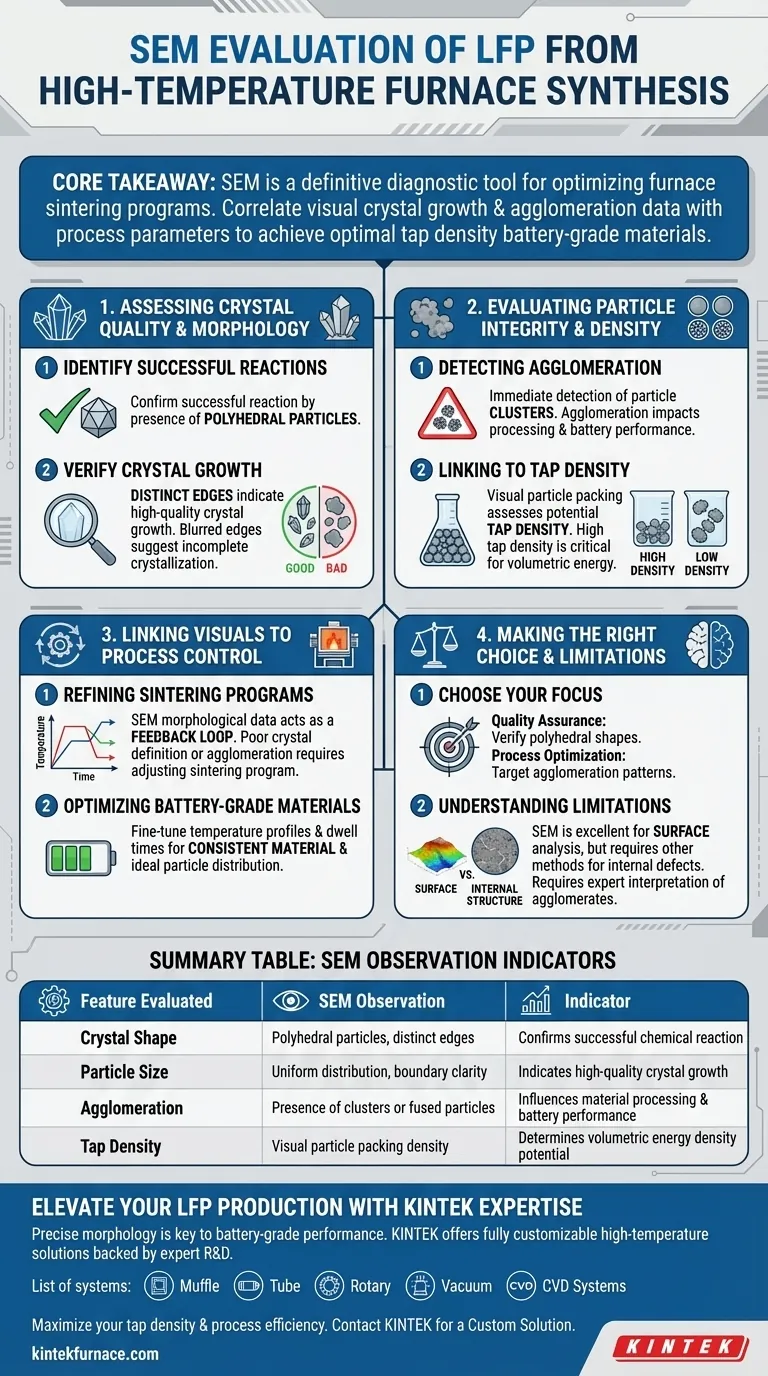

Core Takeaway SEM serves as a definitive diagnostic tool for optimizing furnace sintering programs. By correlating visual evidence of crystal growth and agglomeration with process parameters, you can refine production to achieve battery-grade materials with optimal tap density.

Assessing Crystal Quality and Morphology

Identifying Successful Reactions

The primary indicator of a successful high-temperature synthesis is the shape of the resulting particles.

You should look for polyhedral particles. The presence of these specific geometric shapes confirms that the chemical reaction has proceeded correctly.

Verifying Crystal Growth

Beyond the general shape, the clarity of the particle boundaries is essential.

Distinct edges on the polyhedral particles indicate high-quality crystal growth. If the edges are blurred or undefined, the crystallization process may be incomplete or flawed.

Evaluating Particle Integrity and Density

Detecting Agglomeration

SEM allows for the immediate detection of particle agglomeration, where individual particles clump together.

Identifying these clusters is vital because significant agglomeration can negatively impact the material's processing properties and final performance in a battery.

Linking to Tap Density

The visual data provided by SEM is directly linked to the physical density of the powder.

By observing how particles pack and identifying agglomeration, you can assess the material's potential tap density. High tap density is a critical requirement for battery-grade LFP, as it determines how much energy material can be packed into a finite volume.

Linking Visuals to Process Control

Refining Sintering Programs

The morphological data gathered via SEM acts as a feedback loop for the manufacturing process.

If the SEM reveals poor crystal definition or excessive agglomeration, this indicates that the furnace sintering program needs adjustment.

Optimizing Battery-Grade Materials

Use SEM images to fine-tune temperature profiles and dwell times.

The goal is to produce a consistent material that balances crystal perfection with ideal particle distribution, ensuring the output is truly battery-grade.

Understanding the Limitations

Surface vs. Internal Structure

While SEM is excellent for surface analysis, it relies on visual topography.

It is highly effective for identifying external agglomeration and shape, but it must be paired with other methods to understand internal porosity or atomic-level structural defects.

Interpretation of Agglomeration

Distinguishing between "hard" aggregates (fused particles) and "soft" agglomerates (loosely held particles) can sometimes require careful interpretation of SEM images.

Misinterpreting these can lead to incorrect adjustments in the sintering program, so clear resolution and expert evaluation are required.

Making the Right Choice for Your Goal

To maximize the value of SEM analysis in your LFP synthesis, tailor your focus based on your immediate objective:

- If your primary focus is Quality Assurance: Verify that particles are polyhedral with distinct edges to confirm high-quality crystal growth and a successful reaction.

- If your primary focus is Process Optimization: Target particle agglomeration patterns to refine furnace sintering programs for improved tap density.

Ultimately, SEM transforms the abstract chemistry of high-temperature synthesis into actionable, visual data for process control.

Summary Table:

| Feature Evaluated | SEM Observation Indicator | Impact on LFP Quality |

|---|---|---|

| Crystal Shape | Polyhedral particles with distinct edges | Confirms successful chemical reaction |

| Particle Size | Uniform distribution & boundary clarity | Indicates high-quality crystal growth |

| Agglomeration | Presence of clusters or fused particles | Influences material processing & battery performance |

| Tap Density | Visual particle packing density | Determines volumetric energy density potential |

Elevate Your LFP Production with KINTEK Expertise

Precise morphology is the key to battery-grade performance. KINTEK empowers your research and production with industry-leading high-temperature solutions. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique LFP synthesis requirements.

Our advanced furnaces provide the thermal stability needed to eliminate unwanted agglomeration and achieve perfect polyhedral crystal growth. Maximize your tap density and process efficiency today.

Contact KINTEK for a Custom Solution

Visual Guide

References

- Tengshu Chen, Liyao Chen. Research on the synthesis of lithium iron phosphate using vivianite prepared from municipal sludge. DOI: 10.1038/s41598-025-16378-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a drying oven for oil shale semi-coke? Achieve Precise Sample Standardization

- What is the function of a precision laboratory oven in KNN ceramic pretreatment? Ensure Stoichiometric Accuracy

- What is the purpose of a safety warning system in MDR? Ensure Reactor Integrity and Laboratory Safety

- What is the purpose of adding wax organic binders to glass powder? Enhance Structural Integrity in Glass Sealing

- What role does thermal processing in a furnace play in phase analysis of kaolin? Optimize Your Catalyst Structure

- How does a precision pressure-controlled oxidation device increase carbon chain yield? Optimize Your Annealing Process

- What is the primary purpose of the 600°C annealing treatment? Optimize Silver-Coated Ceramic Performance

- What is the primary function of a high-precision program-controlled furnace? Mastering T6 Heat Treatment of Al-Cu 224