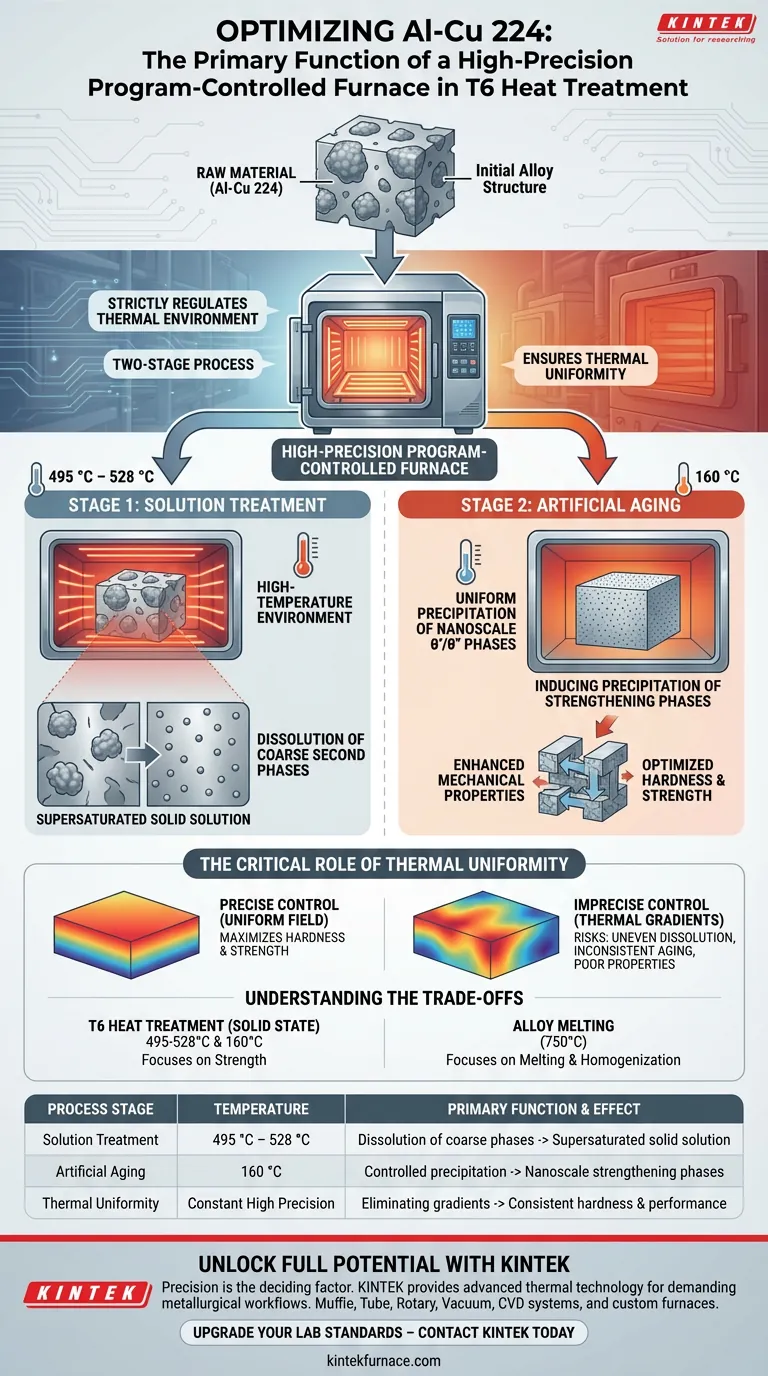

The primary function of a high-precision program-controlled furnace in this context is to strictly regulate the thermal environment required for the microstructural evolution of the Al-Cu 224 alloy.

It executes a two-stage process: creating a uniform thermal field to dissolve coarse phases into a supersaturated solid solution, and subsequently maintaining specific lower temperatures to induce the precipitation of strengthening phases.

The furnace's role is to bridge the gap between raw material and high-performance alloy by ensuring thermal uniformity. It first dissolves coarse second phases at high temperatures and then triggers the precise precipitation of nanoscale $\theta'/\theta''$ phases, which are the fundamental drivers of the alloy's hardness.

The Mechanics of the T6 Heat Treatment

Stage 1: Solution Treatment (495 °C – 528 °C)

The initial function of the furnace is to maintain a high-temperature environment, specifically between 495 °C and 528 °C.

At this range, the equipment ensures the dissolution of coarse second phases found in the raw alloy.

This process transforms the aluminum matrix into a supersaturated solid solution, preparing the material for strengthening.

Stage 2: Artificial Aging (160 °C)

Once the solid solution is formed, the furnace must precisely hold the material at a lower temperature, typically 160 °C.

This stage is critical for inducing the uniform precipitation of nanoscale phases.

These precipitates, specifically the $\theta'$ and $\theta''$ phases, act as barriers to dislocation movement, directly enhancing the mechanical properties.

The Critical Role of Thermal Uniformity

Eliminating Thermal Gradients

The "high-precision" aspect of the furnace is designed to provide a completely uniform thermal field.

Any fluctuation in temperature across the workload could lead to uneven dissolution or inconsistent aging.

Optimizing Hardness

The ultimate goal of this precise control is to maximize the alloy's hardness and mechanical strength.

By ensuring the correct phase evolution occurs throughout the entire component, the furnace guarantees consistent material performance.

Understanding the Trade-offs

Process Distinction vs. Melting

It is crucial not to confuse this heat treatment furnace with the industrial electric furnaces used for initial alloy preparation.

While preparation furnaces operate at 750 °C to melt and homogenize the matrix and additives (like copper and magnesium), the T6 furnace operates strictly in the solid state.

Risks of Imprecise Control

If the furnace fails to maintain the strict temperature windows (e.g., drifting below 495 °C or above 528 °C), the material properties will suffer.

Inadequate heat prevents the full dissolution of coarse phases, while excessive heat or uncontrolled fluctuations can disrupt the formation of the critical nanoscale strengthening phases.

Making the Right Choice for Your Goal

To achieve specific metallurgical outcomes for Al-Cu 224, you must select the correct thermal equipment and parameters.

- If your primary focus is Initial Alloy Preparation: Utilize an industrial electric furnace at roughly 750 °C to ensure full melting and homogenization of the chemical composition.

- If your primary focus is Enhancing Mechanical Strength (T6): Utilize a high-precision program-controlled furnace to execute the solution treatment (495–528 °C) and aging (160 °C) for optimal phase precipitation.

Precision in thermal management is not merely an operational detail; it is the determining factor in unlocking the full mechanical potential of the Al-Cu 224 alloy.

Summary Table:

| Process Stage | Temperature Range | Primary Function | Microstructural Effect |

|---|---|---|---|

| Solution Treatment | 495 °C – 528 °C | Dissolution of coarse phases | Creates supersaturated solid solution |

| Artificial Aging | 160 °C | Controlled precipitation | Formation of nanoscale strengthening phases |

| Thermal Uniformity | Constant High Precision | Eliminating thermal gradients | Ensures consistent hardness and performance |

Unlock the Full Potential of Your Materials with KINTEK

Precision is the deciding factor between a failed casting and a high-performance alloy. KINTEK provides the advanced thermal technology required for the most demanding metallurgical workflows. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your specific Al-Cu 224 heat treatment or alloy development needs.

Don't let thermal fluctuations compromise your mechanical strength. Partner with KINTEK for equipment that guarantees thermal uniformity and process reliability.

Upgrade Your Lab Standards – Contact KINTEK Today

Visual Guide

References

- Esmaeil Pourkhorshid, X.-Grant Chen. Laser-Based Additive Manufacturing Processability and Mechanical Properties of Al-Cu 224 Alloys with TiB Grain Refiner Additions. DOI: 10.3390/ma18030516

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is precise temperature control essential for aluminum alloy solidification? Unlock Superior Material Strength

- What is the role of a 5% N2 + 95% H2 mixture in plasma nitriding? Enhance Fatigue Strength and Eliminate White Layers

- What is the role of high-vacuum sealing technology? Precision Synthesis of High-Performance Copper Sulfide

- What role does a high-performance thermostatic oven play in determining the moisture content of sugar beet by-products?

- How does a vacuum drying oven contribute to the preparation of Na3(VO1-x)2(PO4)2F1+2x? Ensure High-Purity Synthesis

- What are the temperature ranges for low, medium, and high-temperature industrial heating processes? Optimize Your Process with KINTEK

- How does a gas mass flow control system (MFC) prevent copper foil adhesion? Mastering Atmospheric Purity

- Why is a low-temperature annealing treatment necessary for porous gold microspheres? Ensure Structural Integrity