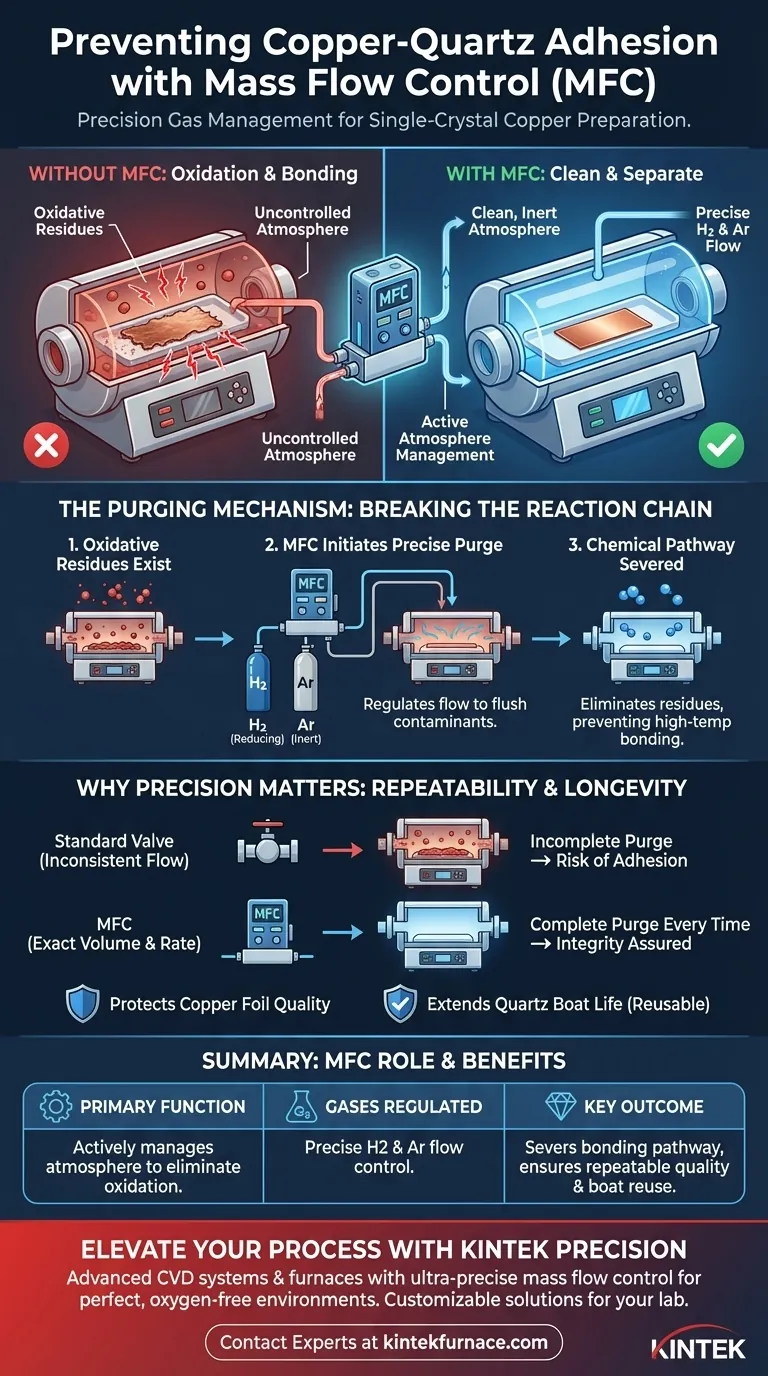

A gas mass flow control system (MFC) prevents adhesion by actively managing the furnace atmosphere to eliminate oxidation. Before the annealing process begins, the MFC precisely regulates the flow of hydrogen and argon to purge the tube furnace. This removal of oxidative residues halts the chemical reactions that would otherwise cause the copper foil to bond to the quartz boat at high temperatures.

Accurate gas control is the primary defense against chemical bonding in this process. By ensuring the complete removal of oxidative contaminants through precise purging, the MFC preserves the integrity of the copper foil and allows for the repeated use of the quartz boat.

The Mechanism of Adhesion Prevention

To understand how the MFC protects the materials, one must understand the chemical environment required for single-crystal copper preparation.

The Role of Oxidative Residues

At high temperatures, copper foil is highly reactive. If oxidative residues remain within the furnace, they trigger chemical reactions.

These reactions are the root cause of the copper foil bonding to the quartz boat. Without a clean atmosphere, the interface between the metal and the quartz becomes chemically active.

The Purging Process

The MFC is responsible for the purging phase prior to annealing. It introduces a specific mixture of hydrogen and argon into the tube furnace.

This is not a passive process; the MFC dictates the exact flow rate required to flush the system. This active displacement forces contaminants out of the environment.

Breaking the Reaction Chain

By accurately controlling these gases, the MFC effectively eliminates the oxidative residues.

When these residues are removed, the chemical pathway for bonding is severed. The copper foil can endure high temperatures without adhering to the quartz surface.

Why Precision Matters

The distinction between a standard valve and a Mass Flow Controller is critical for this application.

Repeatability of the Atmosphere

Simple flow allows gas to enter, but an MFC ensures the volume and rate are exact.

This precision is necessary to guarantee that the purging process is complete every single time. Inconsistent flow leads to leftover residues, which leads to bonding.

Equipment Longevity

Preventing adhesion is not just about the copper; it is about the quartz boat.

When the MFC successfully prevents bonding, the quartz boat remains clean and undamaged. This allows the boat to be reused repeatedly, significantly reducing operational costs.

Operational Considerations and Risks

While the MFC is the solution, it relies on proper configuration to function correctly.

The Consequence of Flow Inaccuracy

If the MFC is calibrated incorrectly or malfunctions, the purging process will be incomplete.

Even trace amounts of oxidative residue can initiate the bonding reaction. The system relies entirely on the MFC's ability to maintain strict flow parameters.

Gas Composition Balance

The system uses both hydrogen and argon.

The MFC must control both gases effectively to create the correct reducing atmosphere. A failure to balance these gases effectively undermines the protection against oxidation.

Making the Right Choice for Your Goal

To maximize yield and equipment life, ensure your flow control strategy is aligned with your specific processing needs.

- If your primary focus is Product Quality: Prioritize MFC precision to ensure zero oxidative residues remain, guaranteeing the integrity of the single-crystal copper foil.

- If your primary focus is Equipment Efficiency: Focus on the reliability of the purging cycle to prevent adhesion, ensuring the quartz boat can be reused for multiple runs without degradation.

The success of single-crystal copper preparation hinges on the MFC's ability to create a chemically inert environment through precise gas management.

Summary Table:

| Feature | Role of MFC in Adhesion Prevention |

|---|---|

| Primary Function | Actively manages furnace atmosphere to eliminate oxidation. |

| Gases Regulated | Precise control of Hydrogen (reducing) and Argon (inert) flow. |

| Mechanism | Complete purging of oxidative residues before annealing begins. |

| Key Outcome | Severs chemical pathways for bonding; protects copper and quartz boat. |

| Equipment Impact | Increases quartz boat longevity and ensures repeatable crystal quality. |

Elevate Your Material Processing with KINTEK Precision

Don’t let atmospheric contamination compromise your single-crystal copper yield or damage your expensive quartz components. KINTEK’s advanced CVD systems and high-temperature tube furnaces are engineered with ultra-precise mass flow control to ensure a perfect, oxygen-free environment every time.

Backed by expert R&D and manufacturing, we offer fully customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of your lab.

Ready to optimize your thermal processing? Contact our technical experts today to discuss a tailored solution for your unique research needs.

Visual Guide

References

- Jia Tu, Mingdi Yan. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. DOI: 10.1021/acsanm.5c00588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Spark Plasma Sintering SPS Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does a hybrid microwave sintering furnace compare to traditional furnaces? Optimize BZT Ceramic Production

- Why must catalysts undergo high-temperature pretreatment? Ensure Precise CO Oxidation Data with KINTEK

- What is the function of a drying oven for oil shale semi-coke? Achieve Precise Sample Standardization

- How does a sealed ceramic boat impact SPAN sulfur content? Unlock 53.62% Retention for High-Energy Cathodes

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- What is the role of an electric blast drying oven in the pretreatment of SBD? Optimize Your Biomass Research

- What are the primary technical advantages of using stainless steel for the construction of horizontal pyrolysis furnace bodies? Durability and Thermal Precision

- What are the advantages of using oriented single-crystal seeds for ZnGeP2? Achieve Precision in Optical Crystal Growth