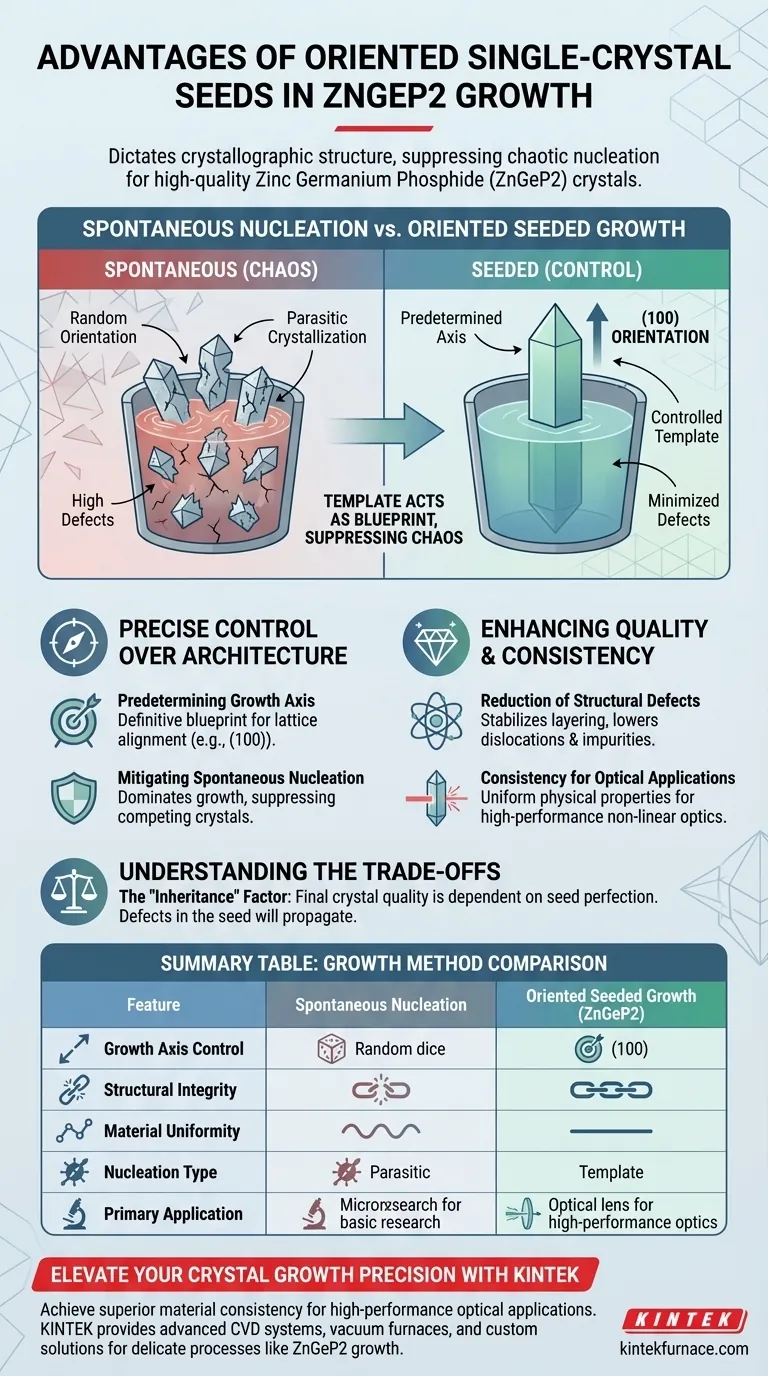

The primary advantage of using an oriented single-crystal seed in the growth of Zinc Germanium Phosphide (ZnGeP2) is the ability to strictly dictate the crystallographic structure of the final material. By utilizing a seed with a specific orientation, such as (100), you effectively predetermine the growth axis rather than leaving it to chance. This technique is critical for suppressing the chaotic nature of spontaneous nucleation, ensuring the production of high-quality crystals with minimized defects.

By acting as a structural template, oriented seeds eliminate the randomness of spontaneous growth. This ensures a reduction in dislocations and parasitic crystallization, delivering the consistent physical properties required for high-performance non-linear optical applications.

Precise Control Over Crystal Architecture

Predetermining the Growth Axis

In unseeded growth, the orientation of a crystal is often random and unpredictable. Using a seed acts as a definitive blueprint for the developing material.

By introducing a seed with a specific orientation, typically (100), the growing crystal is forced to align with that specific lattice structure. This allows engineers to dictate the geometry and optical axes of the crystal from the very start of the process.

Mitigating Spontaneous Nucleation

Spontaneous nucleation occurs when crystals form randomly within the melt without a guiding structure. This often leads to parasitic crystallization, where multiple small, competing crystals grow instead of one large, unified mass.

An oriented seed provides a lower energy surface for growth to begin. This dominates the process, effectively suppressing spontaneous nucleation and ensuring the material grows as a single, cohesive unit.

Enhancing Material Quality and Consistency

Reduction of Structural Defects

The structural integrity of ZnGeP2 is paramount for its end-use performance. Uncontrolled growth often results in dislocations—breaks or misalignments in the crystal lattice.

Seeded growth stabilizes the atomic layering process. This stability significantly lowers the density of dislocations, resulting in a purer internal structure.

Consistency for Optical Applications

ZnGeP2 is primarily valued for its use in non-linear optical applications. These devices require the material to have uniform physical properties throughout its entire volume.

Because the seed ensures a consistent crystallographic orientation, the resulting physical properties remain constant across the crystal. This uniformity is impossible to guarantee with random, spontaneous growth methods.

Understanding the Trade-offs

The "Inheritance" Factor

While seeded growth offers superior control, it introduces a dependency on the quality of the seed itself. The growth process is essentially a copying mechanism.

If the seed contains defects or structural inaccuracies, these imperfections will propagate into the new crystal. Therefore, the advantage of this method is strictly limited by the quality of the initial seed material used.

Making the Right Choice for Your Goal

To maximize the yield and utility of Zinc Germanium Phosphide crystals, align your growth strategy with your specific requirements.

- If your primary focus is High-Fidelity Optical Output: Prioritize oriented seeding to guarantee the consistent physical properties required for non-linear optical devices.

- If your primary focus is Defect Minimization: Use seeded growth to prevent parasitic crystallization and significantly reduce lattice dislocations.

By moving from spontaneous nucleation to seeded growth, you transition from generating random samples to engineering precision optical components.

Summary Table:

| Feature | Spontaneous Nucleation | Oriented Seeded Growth (ZnGeP2) |

|---|---|---|

| Growth Axis Control | Random / Unpredictable | Predetermined (e.g., (100) orientation) |

| Structural Integrity | High risk of dislocations | Minimized defects and dislocations |

| Material Uniformity | Low / Inconsistent | High consistency for optical paths |

| Nucleation Type | Parasitic crystallization | Controlled template growth |

| Primary Application | Basic research samples | High-performance non-linear optics |

Elevate Your Crystal Growth Precision with KINTEK

Are you looking to achieve superior material consistency in your high-performance optical applications? At KINTEK, we understand that precision is the foundation of innovation. Backed by expert R&D and world-class manufacturing, we provide advanced CVD systems, vacuum furnaces, and customizable high-temperature lab solutions specifically designed to support delicate processes like the growth of Zinc Germanium Phosphide (ZnGeP2).

Whether you need to maintain strict thermal gradients for seeded growth or require a bespoke furnace for unique material synthesis, our team is ready to deliver the reliability your research demands. Contact KINTEK today to discuss your specific requirements and discover how our tailored heating solutions can optimize your laboratory’s output.

Visual Guide

References

- Alexey Lysenko, Alexey Olshukov. Band-like Inhomogeneity in Bulk ZnGeP2 Crystals, and Composition and Influence on Optical Properties. DOI: 10.3390/cryst15040382

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does the secondary heat treatment process improve battery performance? Optimize SHPC/N-CNT Composites Today

- Why is an automatically controlled mesh belt quenching line used for bearing rings? Precision & Stability Explained

- What physical environment does a laboratory oven provide for perovskite annealing? Master Thermal Precision & Strain Control

- What is the purpose of using a vacuum dryer for PU and AlN composite sheets? Enhance Thermal & Structural Integrity

- Why is rapid air cooling preferred over furnace cooling for TS-Ir/MnO2? Optimize Catalyst Lattice Strain

- What are the technical advantages of using a pyrolysis furnace vs. an incinerator? Recover Value from Composites

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- How does a vacuum pressure infiltration system contribute to Diamond/Cu composite green bodies? Achieve 60% Density