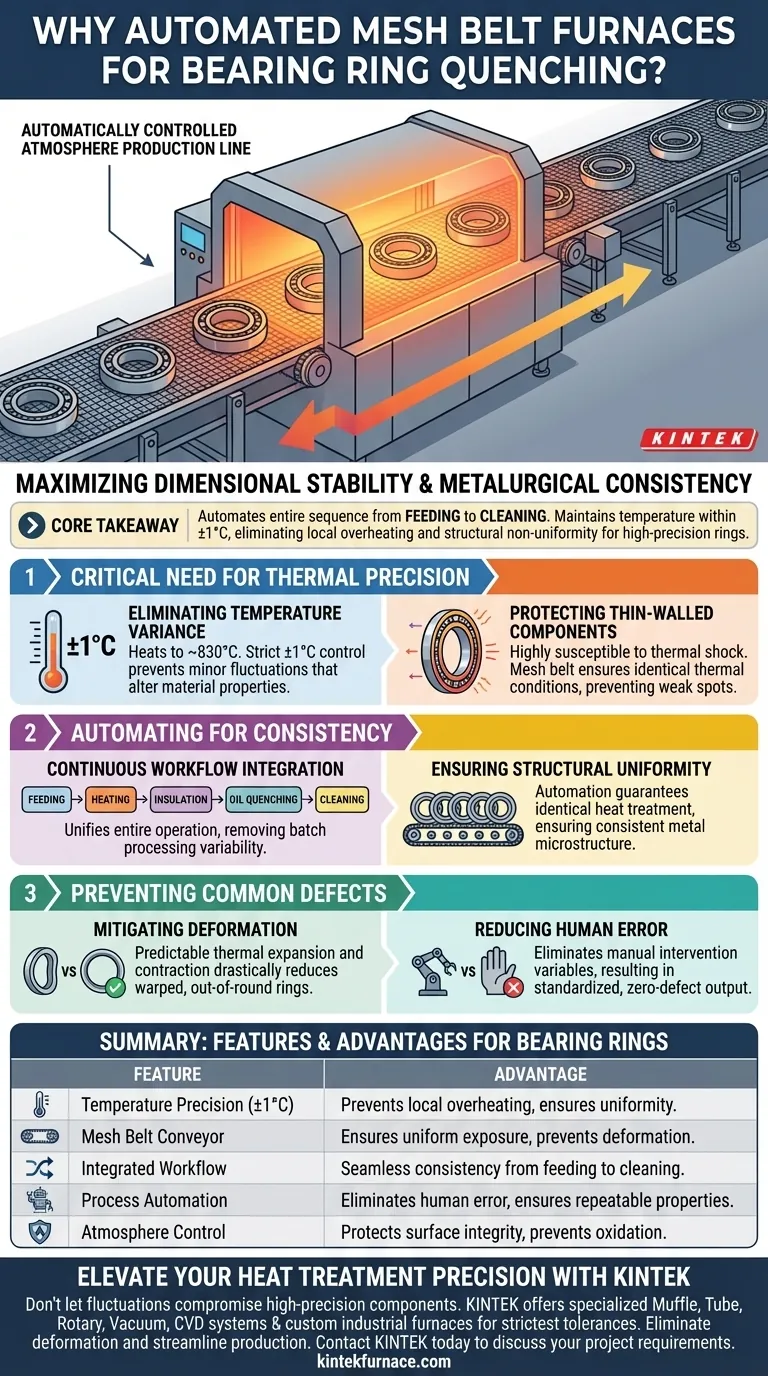

An automatically controlled atmosphere production line with a mesh belt conveyor system is chosen for quenching angular contact ball bearing rings to maximize dimensional stability and metallurgical consistency. This system ensures precise temperature uniformity during the heating process, which is critical for preventing deformation in these thin-walled components.

Core Takeaway By automating the entire sequence—from feeding to cleaning—and maintaining temperature accuracy within $\pm 1^\circ$C, this system eliminates the local overheating and structural non-uniformity that often ruin high-precision bearing rings.

The Critical Need for Thermal Precision

Eliminating Temperature Variance

Angular contact ball bearing rings require heating to approximately 830 degrees Celsius. At this intensity, even minor fluctuations can alter the material's properties. This production line utilizes high-precision control systems to maintain temperatures within a strict plus or minus 1 degree Celsius range.

Protecting Thin-Walled Components

Bearing rings are often thin-walled, making them highly susceptible to thermal shock. Standard heating methods can cause local overheating or underheating. The mesh belt system ensures every millimeter of the ring is exposed to identical thermal conditions, preventing weak spots.

Automating for Consistency

Continuous Workflow Integration

The system does not operate in isolation; it creates a seamless flow. It unifies feeding, heating, insulation, oil quenching, and cleaning into one continuous operation. This integration removes the variability associated with batch processing or manual handling.

Ensuring Structural Uniformity

Automation is the key to repeatability. By mechanically controlling the movement of rings through the furnace on a mesh belt, the system guarantees that every ring undergoes the exact same heat treatment cycle. This prevents structural non-uniformity, ensuring the microstructure of the metal is consistent throughout the batch.

Preventing Common Defects

Mitigating Deformation

Deformation is the primary risk when quenching thin rings. Because the temperature is controlled so precisely, the thermal expansion and subsequent contraction during quenching are predictable. This significantly reduces the rejection rate caused by warped or out-of-round rings.

Reducing Human Error

Manual intervention in heat treatment introduces variables in timing and handling. An automatically controlled line removes these variables. The result is a standardized output where the risk of human-induced defects is effectively zero.

Understanding the Operational Requirements

Dependence on Calibration

While this system offers superior quality, it relies heavily on the accuracy of its sensors. To maintain the $\pm 1^\circ$C precision, the temperature control systems require rigorous calibration. If the control loop drifts, the safeguards against deformation are compromised.

System Specificity

This setup is highly specialized for components like bearing rings. The specific conveyance and atmosphere controls are engineered for parts that demand high structural integrity, rather than generic bulk heat treatment.

Making the Right Choice for Your Production

To determine if this system aligns with your manufacturing goals, consider your specific requirements for precision and volume.

- If your primary focus is Dimensional Accuracy: This system is essential for thin-walled parts where preventing deformation is the highest priority.

- If your primary focus is Process Efficiency: The integration of feeding, quenching, and cleaning offers a streamlined solution for high-volume, continuous production.

Ultimately, this system transforms heat treatment from a variable risk into a precise, repeatable science.

Summary Table:

| Feature | Advantage for Bearing Rings |

|---|---|

| Temperature Precision | Maintains ±1°C to prevent local overheating and structural non-uniformity. |

| Mesh Belt Conveyor | Ensures uniform exposure and prevents deformation in thin-walled components. |

| Integrated Workflow | Combines feeding, heating, quenching, and cleaning for seamless consistency. |

| Process Automation | Eliminates human error and ensures repeatable metallurgical properties. |

| Atmosphere Control | Protects material surface integrity and prevents oxidation during heating. |

Elevate Your Heat Treatment Precision with KINTEK

Don’t let thermal fluctuations compromise the integrity of your high-precision components. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, along with custom-engineered industrial furnace solutions designed to meet your strictest tolerances.

Whether you need to eliminate deformation in thin-walled rings or streamline your production line for maximum efficiency, our lab and high-temp furnaces are fully customizable for your unique needs. Contact KINTEK today to discuss your project requirements and see how our advanced thermal technology can transform your manufacturing consistency.

Visual Guide

References

- Ruijie Gu, Zhongxia Shang. Study on the microstructural evolution mechanism of the angular contact ball bearing rings during the quenching and tempering process. DOI: 10.1038/s41598-024-84570-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the purpose of adding phosphorus pentoxide (P2O5) as a desiccant? Ensure Deep Electrolyte Regeneration

- What are the process advantages of using a microwave hydrothermal high-pressure reactor? Master V-NbOPO4@rGO Synthesis

- Why is it necessary to dry Industrial EAF slag before hydrogen reduction? Crucial Safety and Accuracy Prep

- How does the availability of specialized furnace systems benefit chemical research? Optimize Your Thermal Processing

- Why is a constant temperature drying oven set to 60°C for 24 hours? Optimizing Sr4Al6O12SO4 Powder Quality

- How does a Flash Sintering (FS) system improve efficiency? Unlock Rapid Production for Titanium Diboride Composites

- Why is high temperature control precision essential for SiC/SiC composites? Master Microstructural Engineering

- Why a 1:4 KOH Ratio and 1000 °C are Essential for Chemical Activation? Achieving Ultra-High Surface Area