High-precision temperature control is the defining factor determining the structural integrity and performance of SiC/SiC composites.

In the context of high-temperature heat treatment furnaces, specifically during the Polymer Infiltration and Pyrolysis (PIP) process, exact thermal regulation is required to manage the ceramic matrix phase formation. This precision prevents structural inconsistencies and ensures the material achieves the mechanical properties necessary for high-performance applications.

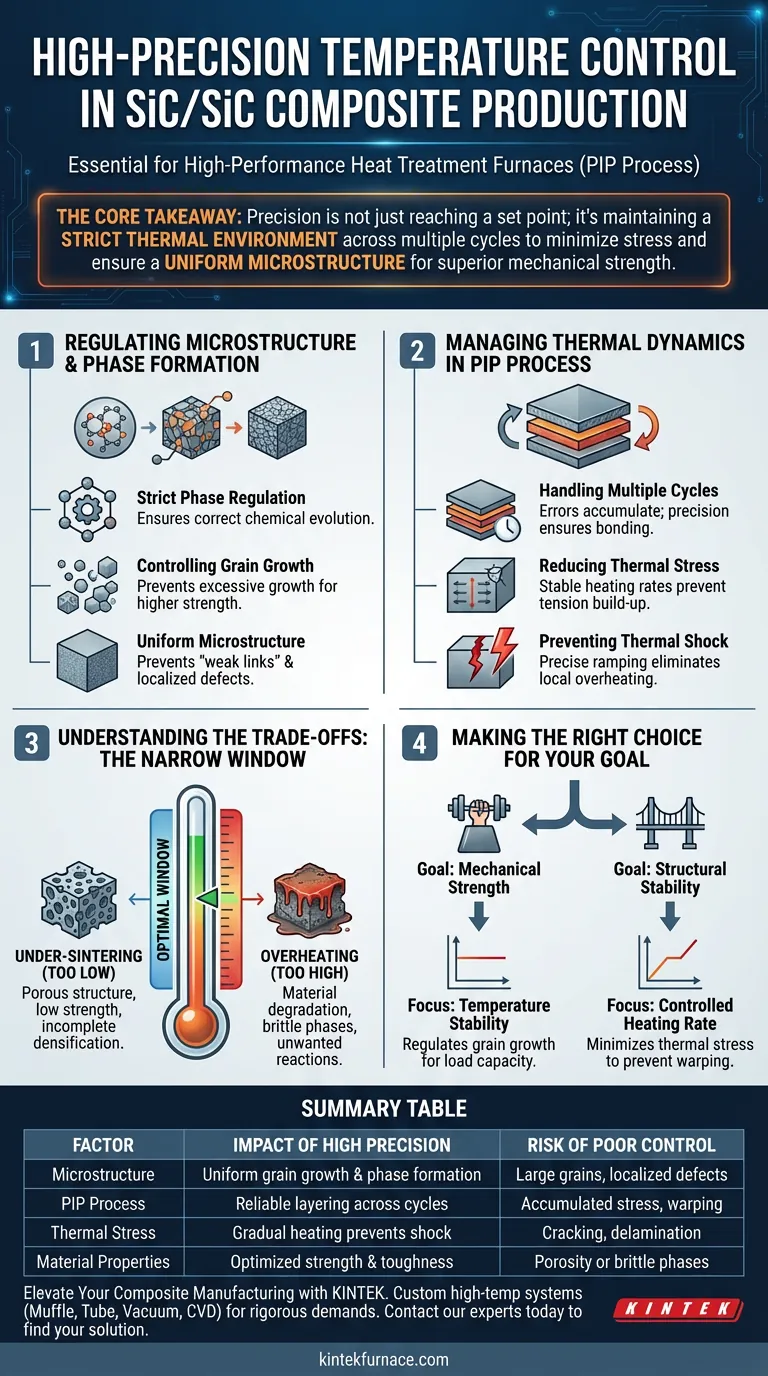

The Core Takeaway

In the production of SiC/SiC composites, temperature precision is not merely about reaching a set point; it is about maintaining a strict thermal environment across multiple processing cycles. This stability minimizes thermal stress accumulation and ensures a uniform microstructure, which is the prerequisite for superior mechanical strength and structural stability.

Regulating Microstructure and Phase Formation

To understand why precision is non-negotiable, you must look at what happens at the microscopic level during the heat treatment process.

Strict Phase Regulation

The primary reference indicates that the ceramic matrix phase formation is sensitive to thermal fluctuations.

Precise control allows you to strictly regulate this formation. This ensures that the matrix evolves chemically into the desired state without deviation, creating a consistent material baseline.

Controlling Grain Growth

Temperature overshoots can lead to uncontrolled grain growth within the ceramic structure.

By maintaining constant temperature accuracy, the furnace prevents grains from growing excessively large. This regulation is vital because fine, uniform grain structures generally yield higher strength and fracture toughness.

Uniform Microstructure Evolution

The goal of the heat treatment is a homogeneous material.

Stable heating ensures that the microstructure evolves uniformly throughout the composite. This prevents the creation of "weak links" or localized defects that could compromise the component under load.

Managing Thermal Dynamics in the PIP Process

The Polymer Infiltration and Pyrolysis (PIP) process presents unique challenges that make thermal precision even more critical.

Handling Multiple Cycles

The PIP process involves repetitive cycles of infiltration and heating to densify the composite.

Any error in temperature control during one cycle does not just vanish; it accumulates. Precision ensures that each layer bonds correctly with the previous one, maintaining integrity throughout the iterative manufacturing steps.

Reducing Thermal Stress Accumulation

Rapid fluctuations or uneven heating creates internal tension.

As noted in the primary reference, stable heating rates are essential to reduce the accumulation of thermal stress. By controlling the rate of temperature change, you prevent the material from developing residual stresses that could lead to cracking or warping.

Preventing Thermal Shock

Supporting data regarding vacuum furnaces highlights the importance of controlled heating rates (e.g., specific ramp rates like 8°C/min).

Precise ramping prevents thermal shock. This eliminates local overheating, which is a common source of internal defects and delamination in composite structures.

Understanding the Trade-offs: The Narrow Processing Window

While high precision is the goal, it is important to understand the specific risks associated with deviating from the optimal temperature window.

The Risk of Under-Sintering

If the temperature control drifts too low, the matrix densification remains incomplete.

This results in a porous structure that lacks the necessary thermal conductivity and mechanical strength, effectively rendering the composite useless for high-performance applications.

The Dangers of Overheating

Conversely, if the temperature drifts too high or is held too long, you risk degrading the material.

Excessive heat can induce unwanted interfacial reactions or local melting of constituents. This degrades the material's properties, often creating brittle phases that reduce the composite's ability to withstand shock.

Making the Right Choice for Your Goal

To optimize your heat treatment process for SiC/SiC composites, you must align your thermal control strategy with your specific material objectives.

- If your primary focus is Mechanical Strength: Prioritize temperature stability to regulate grain growth, as a fine and uniform grain structure directly correlates to higher load-bearing capacity.

- If your primary focus is Structural Stability: Focus on controlling the heating rate (ramp-up) to minimize thermal stress accumulation, preventing warping or cracking during the multiple PIP cycles.

Mastering temperature precision transforms the furnace from a simple heating tool into an instrument of microstructural engineering.

Summary Table:

| Factor | Impact of High Precision | Risk of Poor Control |

|---|---|---|

| Microstructure | Uniform grain growth and phase formation | Large grains and localized defects |

| PIP Process | Reliable layering across multiple cycles | Accumulated thermal stress and warping |

| Thermal Stress | Gradual heating prevents thermal shock | Cracking and delamination from overshoots |

| Material Properties | Optimized mechanical strength and toughness | Porosity (too cold) or brittle phases (too hot) |

Elevate Your Composite Manufacturing with KINTEK

Precise thermal environments are the difference between material failure and high-performance success. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of SiC/SiC composite production. Backed by expert R&D and precision manufacturing, our high-temp furnaces are fully customizable to your specific heating rates and stability requirements.

Ready to optimize your microstructural engineering?

Contact our experts today to find your solution

Visual Guide

References

- Surface Processing and Characterization of Stoichiometry-Varied BaZrS<sub>3</sub> Thin Films. DOI: 10.1021/acsaem.5c01766

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of a heated tundish in a metal powder production system? Optimize Flow and Thermal Consistency

- What is the function of a planetary high-energy ball mill in Al2O3/TiC ceramics? Achieve Sub-Micron Precision Today

- How does a heated substrate platform mitigate the coffee ring effect? Enhance Ag2Se Printing Precision

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What are the key characteristics of furnaces used in 3D printing sintering? Achieve Precision Sintering for High-Quality Parts

- What function does a fluidized bed reactor perform in oil sludge pyrolysis? Enhance Thermal Efficiency

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity

- How does a high-temperature laboratory furnace facilitate the pressureless sintering (PLS) of silicon nitride ceramics?