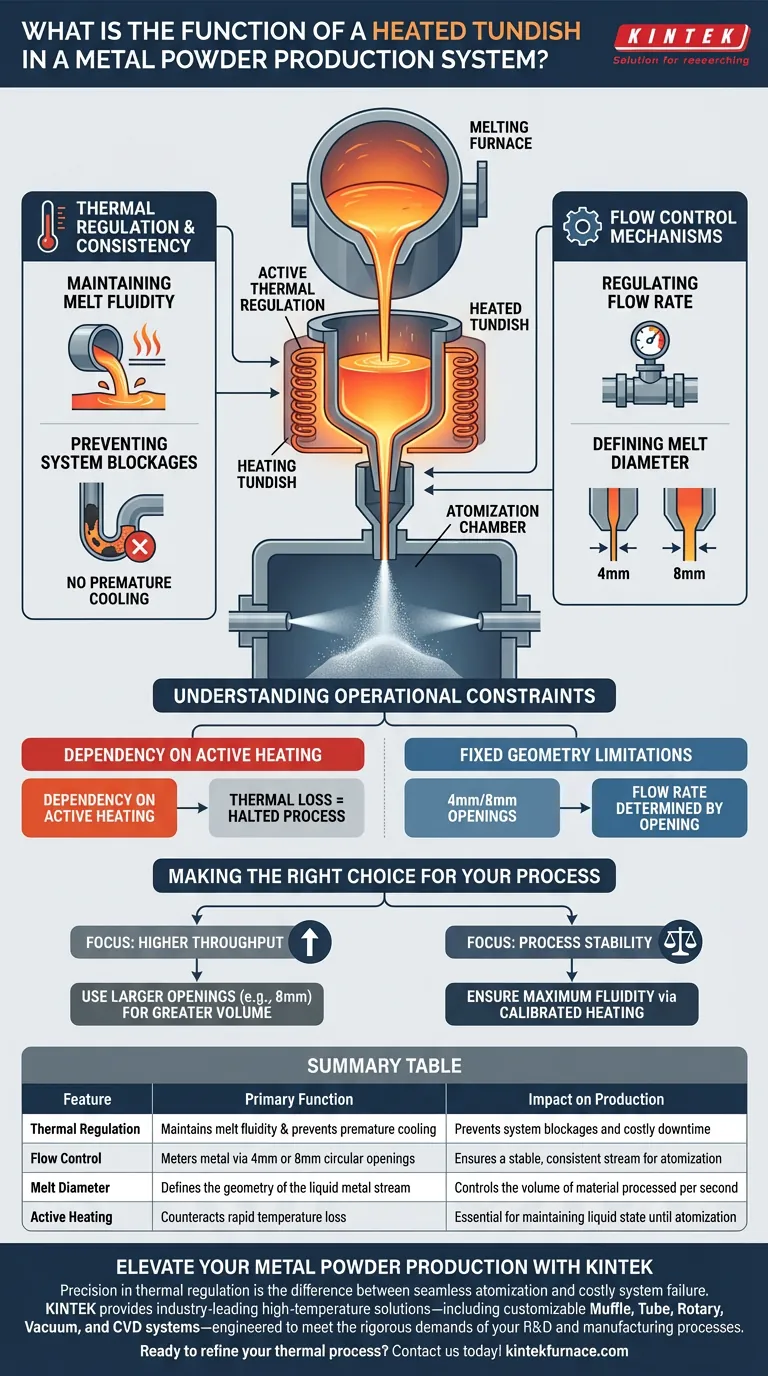

In a metal powder production system, the heated tundish serves as a specialized distribution vessel positioned directly above the atomization chamber. It acts as a temporary reservoir that strictly controls both the temperature and the flow rate of molten metal as it enters the processing zone.

The heated tundish functions as a critical regulator, bridging the gap between bulk melting and atomization. By actively maintaining thermal energy, it ensures the metal remains fluid enough to flow consistently through precise openings, preventing the system blockages that occur with premature cooling.

Thermal Regulation and Consistency

Maintaining Melt Fluidity

The primary challenge in moving molten metal is the rapid loss of temperature, which leads to solidification. The heating element of the tundish counteracts this by keeping the metal at a specific, consistent temperature. This ensures the material maintains the necessary fluidity to move through the system without hesitation.

Preventing System Blockages

If molten metal cools before it reaches the atomization zone, it can harden and clog the machinery. The heated tundish acts as a safeguard against this issue. By preventing premature cooling, it ensures that the metal remains liquid until it passes through the nozzle, avoiding costly production stoppages.

Flow Control Mechanisms

Regulating the Flow Rate

Beyond temperature, the tundish is responsible for the speed at which metal enters the atomization chamber. It utilizes precise circular openings at the bottom of the vessel to meter the liquid. This mechanical control is essential for creating a stable stream of material.

Defining the Melt Diameter

The physical geometry of the tundish outlet dictates the initial characteristics of the metal stream. The system typically employs specific opening sizes, such as 4mm or 8mm diameters. These dimensions directly influence the volume of metal exposed to the atomization process at any given moment.

Understanding Operational Constraints

The Dependency on Active Heating

The effectiveness of the system is entirely dependent on the tundish's heating capability. If the heating function fails or fluctuates, the fluidity of the melt is immediately compromised. This creates a single point of failure where thermal loss results in a halted process.

Fixed Geometry Limitations

The flow rate is determined by the fixed diameter of the opening (e.g., 4mm or 8mm). This means that changing the flow characteristics often requires a physical change to the tundish configuration. You cannot drastically alter the material volume without swapping the opening size.

Making the Right Choice for Your Process

When configuring your tundish parameters, you must balance your need for volume against your need for stream control.

- If your primary focus is higher throughput: structural configurations with larger openings, such as 8mm, allow for a greater volume of material to be processed rapidly.

- If your primary focus is process stability: ensure the heating elements are calibrated to maintain maximum fluidity, as this is the primary defense against blockages regardless of nozzle size.

A heated tundish is not just a container; it is the thermal and mechanical gatekeeper of the atomization process.

Summary Table:

| Feature | Primary Function | Impact on Production |

|---|---|---|

| Thermal Regulation | Maintains melt fluidity & prevents premature cooling | Prevents system blockages and costly downtime |

| Flow Control | Meters metal via 4mm or 8mm circular openings | Ensures a stable, consistent stream for atomization |

| Melt Diameter | Defines the geometry of the liquid metal stream | Controls the volume of material processed per second |

| Active Heating | Counteracts rapid temperature loss | Essential for maintaining liquid state until atomization |

Elevate Your Metal Powder Production with KINTEK

Precision in thermal regulation is the difference between seamless atomization and costly system failure. KINTEK provides industry-leading high-temperature solutions—including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered to meet the rigorous demands of your R&D and manufacturing processes.

Whether you need to optimize melt fluidity or require a bespoke furnace configuration, our expert team is ready to deliver the reliability your lab deserves.

Ready to refine your thermal process? Contact us today to discuss your unique needs!

Visual Guide

References

- С. М. Фролов, T. V. Dudareva. Metal Powder Production by Atomization of Free-Falling Melt Streams Using Pulsed Gaseous Shock and Detonation Waves. DOI: 10.3390/jmmp9010020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What environmental factors can be controlled in a vacuum chamber? Master Pressure, Temperature, Humidity, and Radiation

- Why is a high-precision high-temperature furnace required for mechanical testing? Secure Reliable Material Data

- Why must catalysts undergo high-temperature pretreatment? Ensure Precise CO Oxidation Data with KINTEK

- What are the requirements for synthesizing Magnesium alloys via ampoule method? Expert Synthesis Protocols

- What are the temperature ranges for low, medium, and high-temperature industrial heating processes? Optimize Your Process with KINTEK

- Why is immediate quenching required after CTS treatment of mesoporous carbon? Preserve Your Material’s Atomic Structure

- What is the purpose of using a precision oven for HAp-Fe3O4 drying? Achieve 110°C Stability & High Porosity

- Why is chemical or mechanical cleaning required after high-temperature diffusion coating? Ensure Precision & Quality