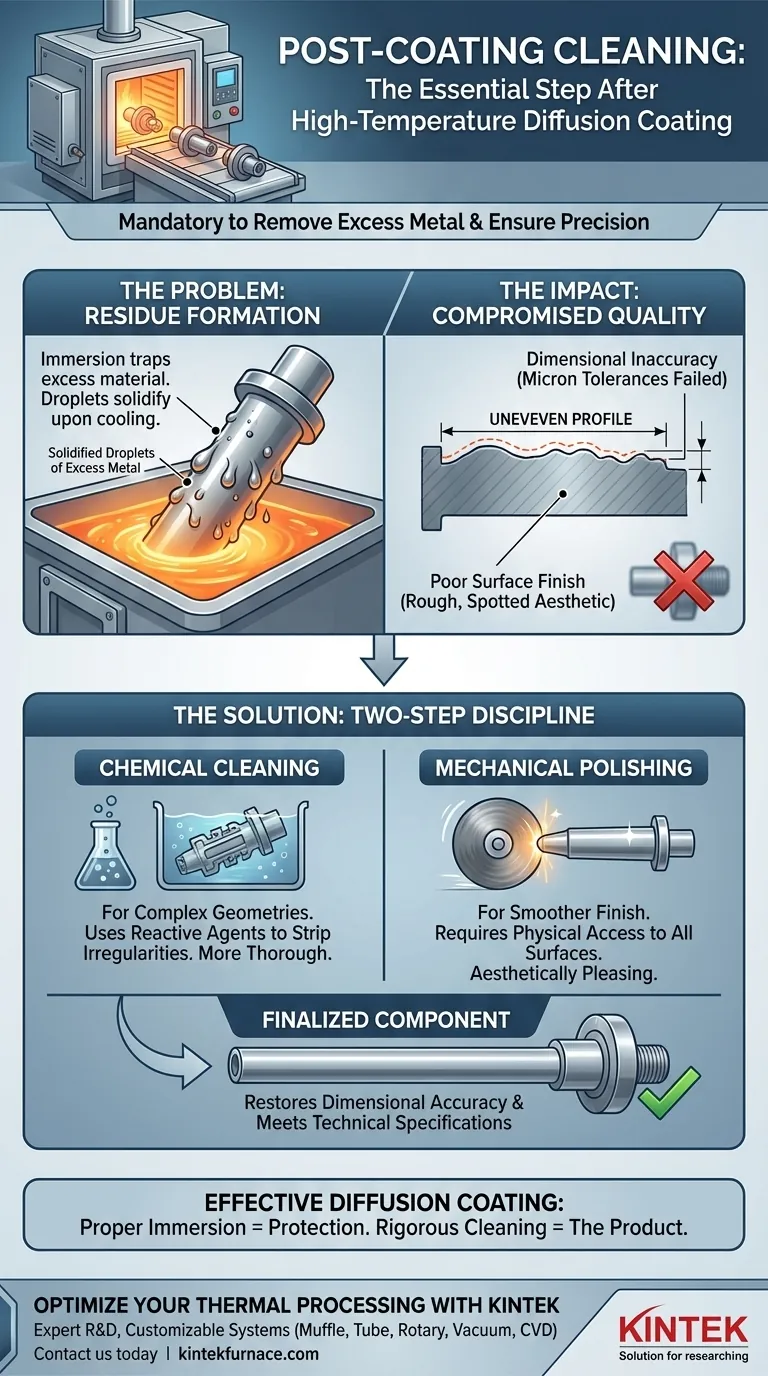

Chemical or mechanical cleaning is mandatory to remove the solidified droplets of excess metal that adhere to the component’s surface after the coating process. Because high-temperature diffusion coating involves immersing parts in low-melting-point metal melts, these residual deposits can distort the part's dimensions and ruin its surface finish, rendering it unsuitable for precision applications.

The immersion process relies on "wetting" to create the coating, but this mechanism inevitably traps excess material on the surface. Cleaning is not merely cosmetic; it is a critical step to strip away these irregularities and ensure the part meets its technical specifications.

The Mechanics of Residue Formation

The Immersion Environment

The diffusion coating process requires the product to be fully immersed in low-melting-point metal melts.

This immersion ensures complete coverage and allows the necessary chemical reactions to occur at the surface level.

The Cooling Aftermath

Once the specimens are removed from the bath and allowed to cool, the liquid metal does not drain away completely.

Small droplets of residual melt cling to the surface and solidify. While the coating itself is integral to the part, these droplets are superficial excess.

Impact on Part Quality

Compromised Dimensional Accuracy

In precision engineering, tolerances are often measured in microns.

The solidified droplets create an uneven surface profile, negatively impacting the dimensional accuracy of the part. Without cleaning, the part may not fit into its assembly or function as designed.

Aesthetic and Surface Standards

Beyond dimensions, the residue creates a rough or spotted appearance.

This significantly degrades the aesthetic quality of the component. To meet standard technical requirements, the surface must be uniform and clean.

Understanding the Trade-offs

The Necessity of Post-Processing

A primary trade-off of the immersion diffusion method is that it does not produce a "net-shape" finished product immediately upon cooling.

Manufacturers must account for the time and cost of a secondary stage—cleaning or polishing. This is an unavoidable step to bridge the gap between the raw coated state and a finished technical product.

Process Selection

The reference notes that either chemical cleaning or mechanical polishing can be used.

Mechanical polishing may offer a smoother finish but requires physical access to all surfaces. Chemical cleaning might be more thorough for complex geometries but involves handling reactive agents.

Finalizing the Component for Use

To ensure your coated parts are ready for service, you must tailor the cleaning process to your specific requirements.

- If your primary focus is Dimensional Precision: Employ cleaning methods that aggressively remove all high spots and droplets to restore the part to its exact specified tolerances.

- If your primary focus is Visual Quality: Prioritize mechanical polishing to achieve a uniform, aesthetically pleasing surface finish free of irregularities.

Effective diffusion coating is a two-step discipline: proper immersion creates the protection, but rigorous cleaning creates the product.

Summary Table:

| Aspect | Problem Without Cleaning | Goal of Post-Processing |

|---|---|---|

| Dimensional Accuracy | Solidified droplets cause uneven profiles and tolerance failures. | Restores exact dimensions for precision engineering. |

| Surface Finish | Rough, spotted, and aesthetically poor appearance. | Produces a smooth, uniform, and professional finish. |

| Functional Fit | Excess material prevents proper assembly. | Ensures parts fit and function within their designated systems. |

| Processing Method | Residual low-melting-point metal remains. | Uses chemical or mechanical means to strip irregularities. |

Optimize Your Thermal Processing with KINTEK

Precision coating is only as good as the finish. At KINTEK, we understand that high-temperature diffusion coating requires the right equipment and rigorous post-processing to meet technical specifications. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique lab and industrial needs.

Ready to enhance your material properties and achieve superior dimensional accuracy? Contact our experts today to find the perfect high-temperature furnace solution for your application!

Visual Guide

References

- Ismatov Jumaniez Faizullaevich. Mplementation Of The Process Of High Temperature Diffusion Treatment. DOI: 10.37547/ajast/volume05issue11-22

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are some examples of high-temperature industrial heating processes? Explore Key Applications and Benefits

- What are the advantages of continuous furnaces? Boost Efficiency and Cut Costs in High-Volume Production

- What is the function of a vacuum drying oven in CMS synthesis? Ensure High-Purity Precursor Integrity

- Why is HR-TEM used after high-temperature heat treatment? Visualize structural evolution and material integrity.

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What are the benefits of adding calcium oxide in sludge thermal treatment? Boost Efficiency & Reduce Emissions

- What are the main advantages of crucible furnaces? Unmatched Flexibility for Small-Scale Melting

- How does direct technical consultation support the acquisition of customized high-temperature furnace systems? Expert R&D