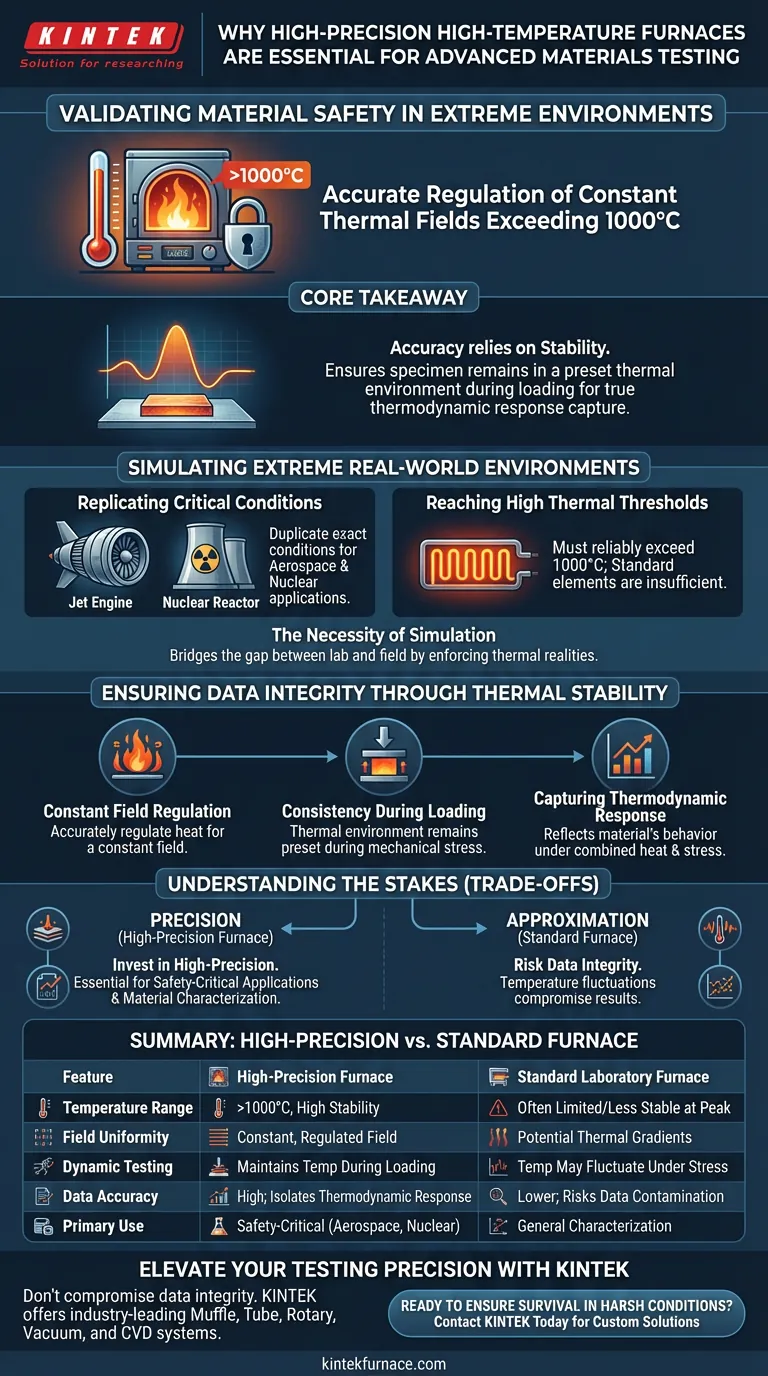

High-precision high-temperature furnaces are required to validate material safety in extreme environments. These specialized furnaces do more than simply heat a sample; they generate and rigorously regulate a constant thermal field, often exceeding 1000°C. This precise control is the only way to ensure mechanical test results accurately reflect how a material will behave inside critical machinery, such as jet engines or nuclear reactors.

Core Takeaway: Accuracy in mechanical testing relies on stability. A high-precision furnace ensures the material specimen remains in a "preset" thermal environment throughout the loading process, allowing engineers to capture the material's true thermodynamic response under real-world stress.

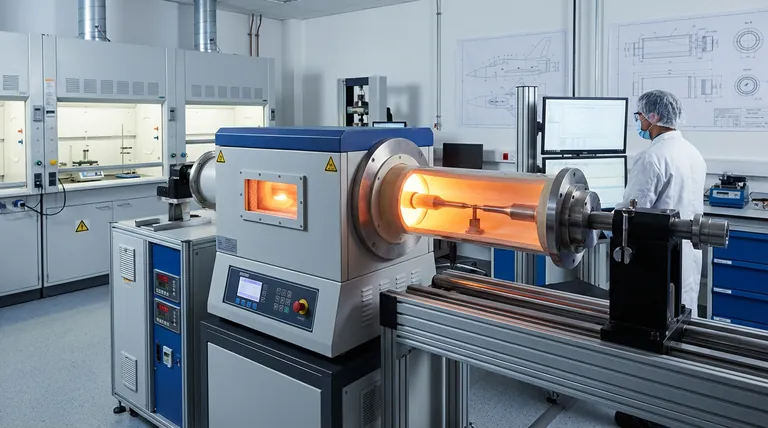

Simulating Extreme Real-World Environments

Replicating Critical Conditions

Advanced materials often serve in unforgiving environments. To validate a material for use in a jet engine or a nuclear reactor, the testing setup must duplicate those exact conditions.

Reaching High Thermal Thresholds

Standard heating elements are insufficient for these applications. The furnace must be capable of providing a high-temperature field that reliably exceeds 1000°C.

The Necessity of Simulation

Without this capability, testing is merely theoretical. The furnace bridges the gap between the lab and the field by strictly enforcing the thermal realities the material will face in service.

Ensuring Data Integrity Through Thermal Stability

Constant Field Regulation

Getting a sample hot is easy; keeping it at a precise temperature is difficult. The core function of these furnaces is to accurately regulate the heat to maintain a constant field.

Consistency During Loading

Mechanical testing involves applying physical stress (load) to a specimen. The furnace ensures that the thermal environment remains preset and unchanging, even as the material deforms under this load.

capturing Thermodynamic Response

Materials behave differently when heat and physical stress interact. High-precision thermal control allows for an accurate reflection of the material's thermodynamic response, ensuring the data collected is valid for engineering decisions.

Understanding the Stakes (Trade-offs)

Precision vs. Approximation

Using a lower-precision heating source may save resources, but it compromises data integrity. If the temperature fluctuates during loading, you cannot distinguish between mechanical failure and thermal failure.

The Cost of Accuracy

Achieving temperatures >1000°C with tight regulation requires sophisticated infrastructure. However, for safety-critical applications, the "cost" of poor data is far higher than the investment in high-precision equipment.

Making the Right Choice for Your Goal

To determine if your testing protocol requires this level of precision, consider the end-use of your material.

- If your primary focus is Safety-Critical Applications (e.g., Aerospace, Nuclear): You must use high-precision furnaces to guarantee the material can survive the specific thermodynamic stresses of the operating environment.

- If your primary focus is Material Characterization: You need the strict regulation capability to isolate variables, ensuring that observed changes are due to the material's properties, not temperature fluctuations.

Precise thermal control is the fundamental requirement for transforming raw data into reliable engineering confidence.

Summary Table:

| Feature | High-Precision Furnace | Standard Laboratory Furnace |

|---|---|---|

| Temperature Range | >1000°C with high stability | Often limited or less stable at peak |

| Field Uniformity | Constant, regulated thermal field | Potential for thermal gradients |

| Dynamic Testing | Maintains temp during mechanical loading | Temp may fluctuate under stress |

| Data Accuracy | High; isolates thermodynamic response | Lower; risks data contamination |

| Primary Use | Safety-critical (Aerospace, Nuclear) | General material characterization |

Elevate Your Testing Precision with KINTEK

Don't compromise your data integrity with inconsistent thermal environments. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding mechanical testing requirements. Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique thermodynamic simulation needs.

Ready to ensure your materials survive the world's harshest conditions?

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Priyanka Gupta, Raghad Ahmed Hussien. RETRACTED: High-Temperature Mechanical Characterization of Materials for Extreme Environments. DOI: 10.1051/e3sconf/202450501006

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a specific glass slide used to cover Zinc powder? Mastering ZnO Nanostructure Precision

- How does the introduction of silicon dioxide (SiO2) facilitate the preparation of pure-phase olivine phosphors via HTSSR?

- Why must calcination equipment be used to pre-treat ZSM-5 zeolite? Ensure Accurate VOC Adsorption Testing

- Why is an air-ventilated oven necessary for GFPP surface modification? Achieve Maximum Solar Reflectance

- How does programmed temperature control assist in Ti(C,N)-FeCr cermet degassing? Achieve Structural Integrity

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity

- Why is a blast drying oven required for the pretreatment of chromite pellets? Prevent Structural Failure & Steam Cracks

- Why is the preheating zone of a walking-beam furnace critical for Titanium/Steel clad plates? Minimize Thermal Stress