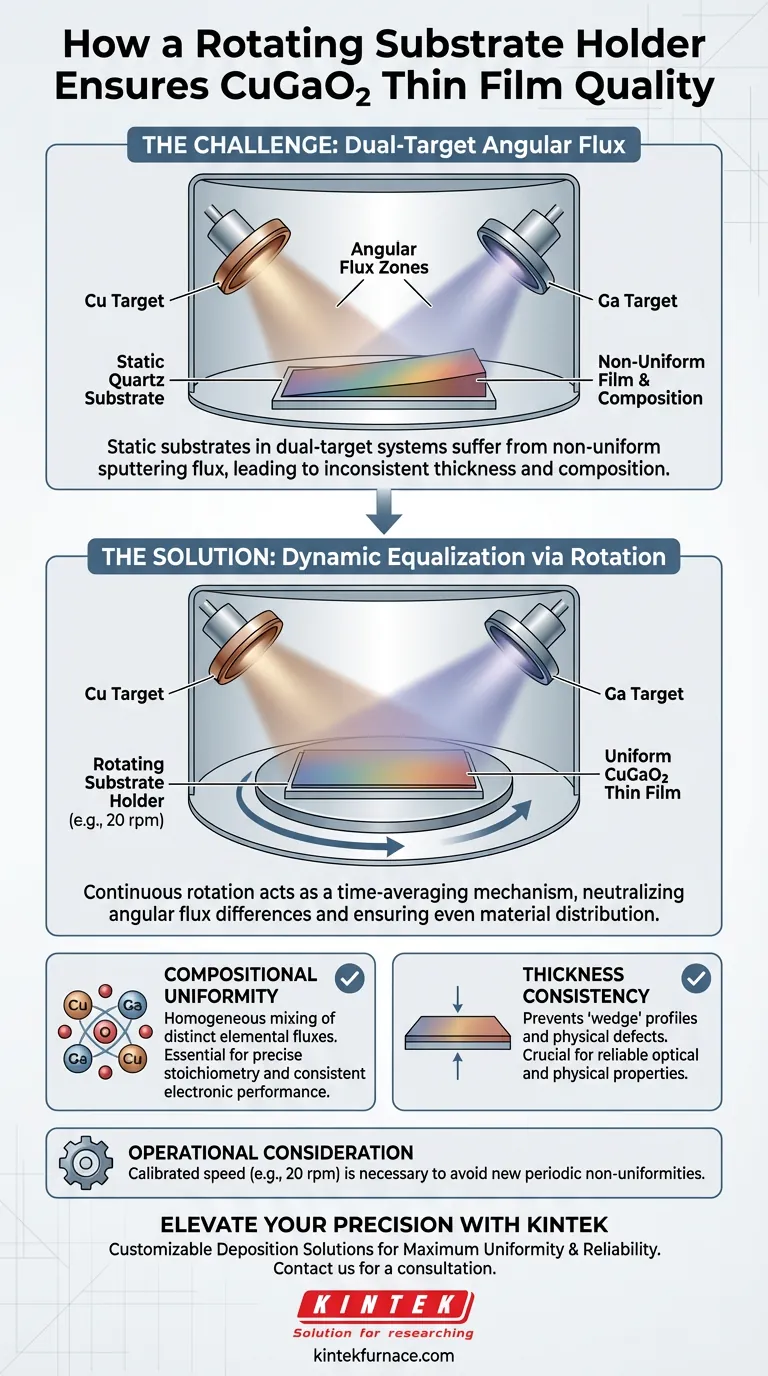

A rotating substrate holder acts as a dynamic equalizer during the dual-target sputtering process. By continuously spinning the quartz substrate—typically at speeds such as 20 rpm—it actively compensates for the uneven distribution of material caused by the angular positioning of two separate targets. This mechanical action is the primary driver for ensuring that the resulting CuGaO2 thin films exhibit consistent thickness and uniform chemical composition across the entire surface area.

In dual-target configurations, the geometric angle between sources creates inherent zones of uneven flux. Rotation eliminates these localized variations, ensuring that the CuGaO2 film possesses identical physical and chemical properties at every point on the substrate.

The Mechanics of Deposition Uniformity

To understand the value of rotation, one must first understand the geometry of the deposition environment.

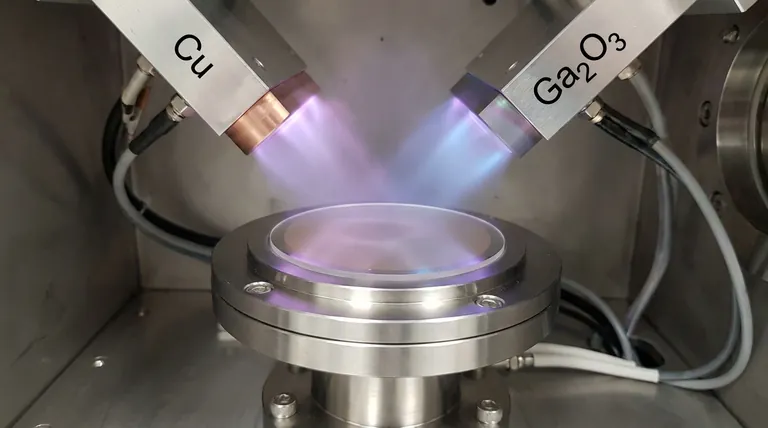

Counteracting Angular Flux

In a dual-target system, the sputtering sources are often angled toward the substrate rather than facing it directly. This geometry naturally creates a non-uniform sputtering flux, where certain areas of the substrate receive more material than others.

The Role of Dynamic Motion

The rotating holder introduces a time-averaging effect to the deposition process. By rotating the substrate (e.g., at 20 rpm), the system prevents any single area of the film from remaining static relative to the targets.

This continuous motion ensures that the material arriving from the angled targets is distributed evenly, effectively neutralizing the directionality of the source flux.

Impact on CuGaO2 Film Quality

The quality of CuGaO2 thin films is defined by two major metrics: stoichiometry (composition) and geometry (thickness). Rotation is critical for both.

Achieving Compositional Uniformity

CuGaO2 is a complex compound that requires a precise ratio of Copper, Gallium, and Oxygen. Without rotation, the angular differences between targets could lead to phase separation or areas rich in one element but poor in another.

Rotation ensures distinct elemental fluxes are mixed homogeneously. This results in high compositional uniformity across the quartz substrate, which is essential for consistent electronic performance.

Ensuring Thickness Consistency

Variations in film thickness can drastically alter the optical and electrical properties of a thin film. A static substrate in a dual-target system would likely develop a "wedge" profile or varying depths.

The rotating holder ensures that the accumulation of material is identical across the surface. This leads to high levels of thickness consistency, preventing physical defects in the final layer.

Operational Considerations and Trade-offs

While rotation is a solution to non-uniformity, it introduces specific operational requirements that must be managed.

The Necessity of Calibrated Speed

The effectiveness of the process relies on maintaining a consistent rotational speed, such as the cited 20 rpm.

If the rotation is too slow relative to the deposition rate, the "averaging" effect may not fully resolve the flux differences. Conversely, inconsistent speeds could introduce new periodic non-uniformities.

System Complexity

Implementing a rotating stage adds mechanical complexity to the vacuum chamber compared to a static mount. However, in dual-target setups, this is not an optional feature but a fundamental requirement to overcome the limitations of the source geometry.

Making the Right Choice for Your Goal

The use of a rotating substrate holder is the defining factor in transitioning from a rough deposition to a device-quality film.

- If your primary focus is Electronic Reliability: The rotating holder ensures compositional uniformity, guaranteeing that the CuGaO2 stoichiometry required for proper conductivity exists across the entire film.

- If your primary focus is Optical or Physical Precision: The rotation provides thickness consistency, ensuring the film has a flat, uniform profile essential for subsequent layering or optical measurements.

By integrating a rotating holder operating at optimized speeds like 20 rpm, you convert the geometric liability of dual targets into a capability for high-quality, uniform film growth.

Summary Table:

| Feature | Impact on CuGaO2 Quality | Mechanical Function |

|---|---|---|

| Thickness Consistency | Prevents "wedge" profiles and physical defects | Time-averaging of material accumulation |

| Compositional Uniformity | Ensures precise stoichiometry and phase purity | Homogeneous mixing of distinct elemental fluxes |

| Angular Compensation | Neutralizes directionality of angled targets | Dynamic equalization of sputtering flux |

| Rotational Speed (20 rpm) | Guarantees device-quality, flat film profiles | Prevents localized material variations |

Elevate Your Thin Film Precision with KINTEK

Don't let geometric limitations compromise your material research. KINTEK provides industry-leading deposition solutions designed for maximum uniformity and reliability. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab high-temp needs.

Whether you are developing CuGaO2 thin films or advanced semiconductors, our systems deliver the consistency your data demands.

Ready to optimize your sputtering process?

Contact KINTEK today for a customized consultation

Visual Guide

References

- Akash Hari Bharath, Kalpathy B. Sundaram. Deposition and Optical Characterization of Sputter Deposited p-Type Delafossite CuGaO2 Thin Films Using Cu2O and Ga2O3 Targets. DOI: 10.3390/ma17071609

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does heat treatment affect the TPU encapsulation layer? Optimize Flexible Sensor Durability & Bonding

- What is the significance of calculating AC impedance in the power control of indirect heating resistance furnaces?

- What are the three main categories of thin-film deposition methods? Essential Guide for Material Engineers

- What are the methods of heat transfer in furnaces? Master Heat Control for Better Results

- Why is the initial concentration of siloxane systems performed in a vacuum oven? Achieve Defect-Free Material Curing

- What is the purpose of using a laboratory electric thermostatic blast drying oven in the pretreatment of sludge? Efficiency & Accuracy

- What is the purpose of bottom-entry argon injection? Enhance Lithium-ion Battery Safety & Purge Efficiency

- Why is a vacuum storage environment necessary for solid polymer electrolyte films? Ensure Film Integrity & Data Accuracy