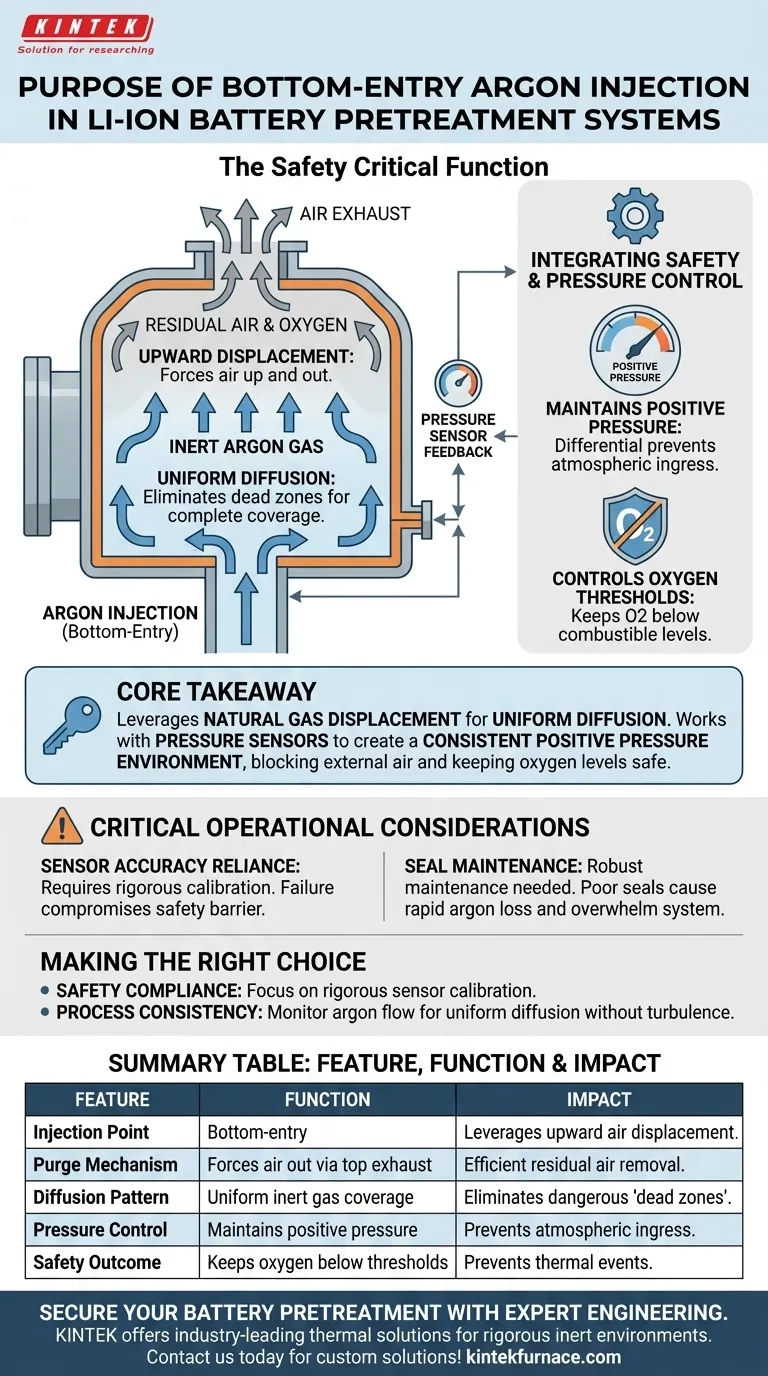

The bottom-entry argon injection design serves a critical safety function by utilizing the physical principle of upward displacement to purge residual air from the battery pretreatment system. By introducing the gas from the bottom, the system forces existing air upward and out, ensuring the inert gas covers the entire working volume uniformly.

Core Takeaway This piping configuration leverages natural gas displacement to achieve uniform inert gas diffusion while working in tandem with pressure sensors. The result is a consistent positive pressure environment that blocks external air ingress and keeps oxygen levels below combustible safety thresholds.

The Mechanics of Efficient Purging

Leveraging Upward Displacement

The primary mechanism at work here is the upward displacement effect. By introducing argon at the base of the chamber, the flow naturally pushes the lighter, residual air upward toward exhaust points. This physical displacement is more effective at clearing the volume than simple dilution or top-down injection methods.

Achieving Uniform Diffusion

A key objective in lithium-ion battery processing is eliminating "dead zones" where oxygen might linger. Bottom-entry piping facilitates the uniform diffusion of inert gas throughout the entire working volume. This ensures that the protective argon atmosphere blankets every component equally.

Integrating Safety and Pressure Control

Maintaining Positive Pressure

The piping design does not operate in isolation; it is integrated with a pressure sensing system. This combination allows the chamber to maintain a slight positive pressure environment. This differential is crucial because it ensures that if there is any breach in the containment, gas flows out rather than air flowing in.

Preventing Atmospheric Ingress

The positive pressure created by this injection method effectively prevents external air from leaking through seals. Even if mechanical seals are not perfectly airtight, the outward pressure creates a barrier against the surrounding atmosphere.

Controlling Oxygen Thresholds

The ultimate goal of this design is hazard prevention. By rigorously excluding air, the system ensures internal oxygen concentrations remain below safety thresholds. This is a non-negotiable requirement for preventing thermal events during the pretreatment of volatile battery materials.

Critical Operational Considerations

Reliance on Sensor Accuracy

While effective, this system relies heavily on the pressure sensing feedback loop. If the sensors fail or drift, the system may lose positive pressure without warning, compromising the safety barrier.

Seal Maintenance

Although positive pressure mitigates the risk of leaks, it does not eliminate the need for robust mechanical maintenance. Poor seal integrity will lead to rapid loss of argon, increasing operational costs and potentially overwhelming the injection system's ability to maintain pressure.

Making the Right Choice for Your Goal

To ensure this piping design delivers the intended safety benefits, focus on the following operational priorities:

- If your primary focus is Safety Compliance: rigorously calibrate your pressure sensing system to ensure the positive pressure environment never fluctuates below the required margin to exclude oxygen.

- If your primary focus is Process Consistency: monitor the argon flow rate to confirm it is sufficient to achieve uniform diffusion without creating turbulence that could trap residual air pockets.

An effective bottom-entry design transforms argon injection from a simple utility into a dynamic safety barrier against combustion.

Summary Table:

| Feature | Function & Impact |

|---|---|

| Injection Point | Bottom-entry to leverage upward displacement of air |

| Purge Mechanism | Efficiently forces residual air out via top exhaust points |

| Diffusion Pattern | Uniform inert gas coverage; eliminates dangerous 'dead zones' |

| Pressure Control | Maintains positive pressure to prevent atmospheric ingress |

| Safety Outcome | Keeps oxygen below combustible thresholds to prevent thermal events |

Secure Your Battery Pretreatment with Expert Engineering

Don't compromise on safety when handling volatile lithium-ion materials. KINTEK provides industry-leading thermal solutions, including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain rigorous inert environments.

Our expert R&D and manufacturing teams ensure every furnace is optimized for uniform gas diffusion and precise pressure control to keep your laboratory safe and efficient.

Ready to upgrade your high-temperature processes? Contact KINTEK today to discuss your unique project requirements and discover our custom-built solutions!

Visual Guide

References

- Sung-Hoon Jung, Jei‐Pil Wang. Development of a discharge-free pre-treatment device for spent lithium-ion batteries under an inert atmosphere. DOI: 10.53894/ijirss.v8i9.10684

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- What is the technical necessity of sealing quartz ampoules at 10^-5 mbar for CVT? Ensure Crystal Purity

- What function does a laboratory drying oven serve in the processing of PZT precursor powders? Optimize Ceramic Quality

- How does a needle valve control silver foil surface quality for graphene growth? Prevent defects with pressure control.

- How does a continuous argon flow heating chamber aid CMF testing? Ensure Pure Thermal Analysis

- How does a high-precision temperature control system influence the nanoparticle size? Master Catalyst Activation

- How do precision electric drying ovens control the precipitation of strengthening phases in recycled aluminum alloys?

- What role does quartz sand filler play in a crystal growth furnace? Enhance Thermal Symmetry and Yield

- What challenges are associated with batch furnaces? Overcome Inefficiency and Quality Issues