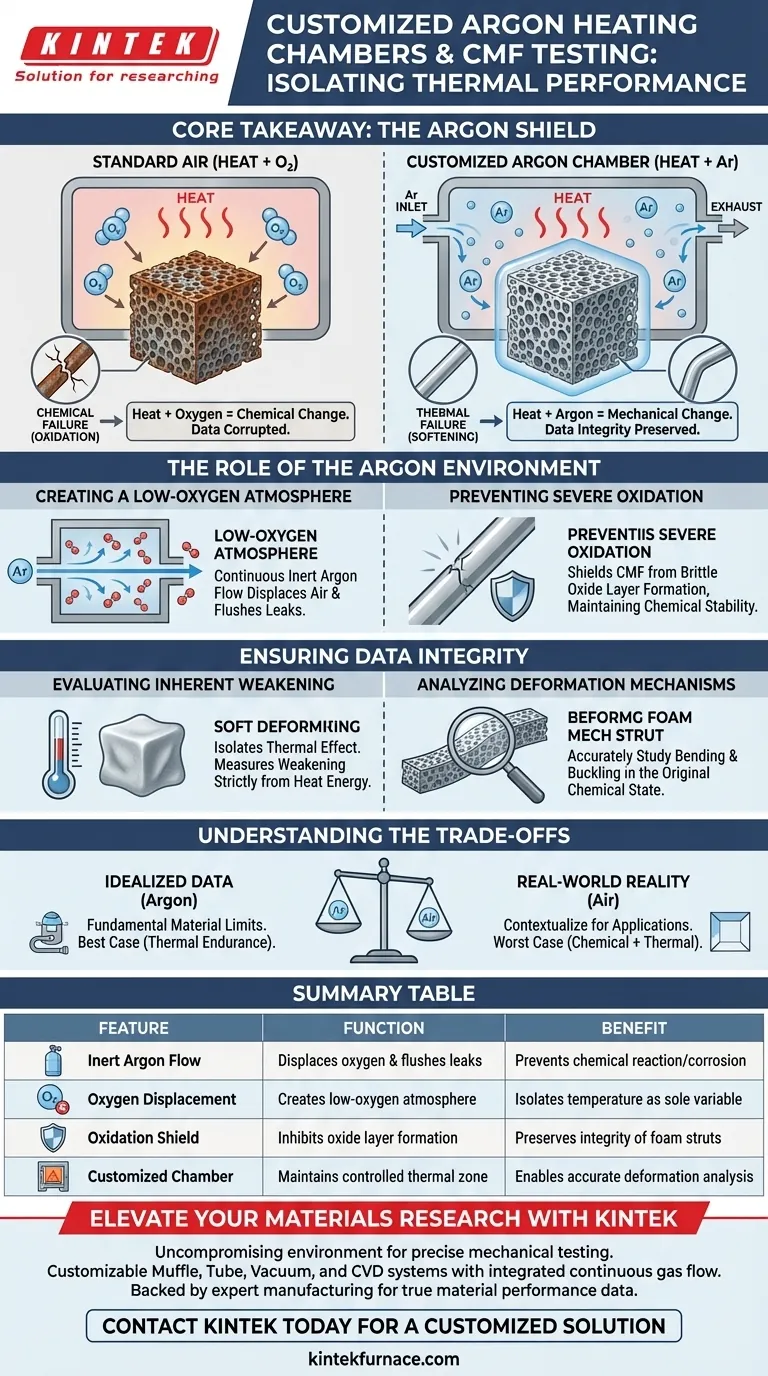

High-temperature mechanical testing requires strict environmental control. A customized heating chamber equipped with a continuous flow of argon gas serves a critical function: it actively displaces oxygen from the testing zone. By establishing this low-oxygen environment, the setup prevents severe oxidation of the Composite Metal Foam (CMF) while it is subjected to elevated temperatures.

Core Takeaway Heat alone changes a material's mechanics, but heat combined with oxygen changes its chemistry. The argon environment acts as a shield, isolating the variable of temperature to ensure that any observed failure is due to the material's inherent thermal limits, not surface corrosion.

The Role of the Argon Environment

Creating a Low-Oxygen Atmosphere

The primary function of the continuous argon flow is to displace the air naturally present within the chamber. Because argon is an inert gas, it does not react with the Composite Metal Foam.

Maintaining a continuous flow is essential. It ensures that any oxygen that might seep into the chamber is immediately flushed out, maintaining a pristine, protective atmosphere throughout the duration of the test.

Preventing Severe Oxidation

Metals exposed to high temperatures in standard air are highly susceptible to rapid oxidation. This chemical reaction creates a brittle oxide layer on the surface of the material.

For Composite Metal Foam, this surface degradation would compromise the structural struts. The argon shield effectively prevents this environmental degradation, keeping the material chemically stable even as it reaches extreme heat.

Ensuring Data Integrity

Evaluating Inherent Weakening

The scientific goal of these tests is to understand how the material behaves under thermal stress. Researchers need to measure the inherent weakening of the metal caused strictly by the energy of the heat.

If oxidation were allowed to occur, the data would be corrupted. It would be impossible to determine if the material failed because it got soft (thermal effect) or because it rusted and became brittle (chemical effect).

Analyzing Deformation Mechanisms

CMF relies on specific internal mechanisms to handle loads, such as the bending or buckling of its metallic walls. To accurately study these deformation mechanisms, the metal must remain in its original chemical state.

The customized chamber allows researchers to observe exactly how the foam deforms under heat and pressure, providing a clear picture of its mechanical performance without the interference of surface damage.

Understanding the Trade-offs

Idealized vs. Real-World Conditions

While testing in argon provides accurate material data, it represents an idealized scenario. It tells you how the CMF behaves in a vacuum or protected environment.

If the actual application of the CMF involves exposure to air at high temperatures, the argon test data must be contextualized. It represents the "best case" mechanical limit, excluding the "worst case" chemical reality of an oxygen-rich environment.

Making the Right Choice for Your Goal

To obtain valid mechanical data for Composite Metal Foam, you must control the testing atmosphere.

- If your primary focus is fundamental material science: Use continuous argon flow to isolate thermal softening and understand the material's theoretical limits.

- If your primary focus is failure analysis: Ensure the argon flow is sufficient to prevent any oxidation, as even minor surface corrosion can alter the deformation data of the foam struts.

Ultimately, the customized argon chamber is the only way to guarantee that your test results measure thermal endurance rather than chemical decay.

Summary Table:

| Feature | Function in CMF Testing | Benefit to Data |

|---|---|---|

| Inert Argon Flow | Displaces oxygen and flushes leaks | Prevents chemical reaction/corrosion |

| Oxygen Displacement | Creates a low-oxygen atmosphere | Isolates temperature as the sole variable |

| Oxidation Shield | Inhibits brittle oxide layer formation | Preserves integrity of foam struts |

| Customized Chamber | Maintains controlled thermal zone | Enables accurate deformation analysis |

Elevate Your Materials Research with KINTEK

Precise mechanical testing requires an uncompromising environment. KINTEK provides industry-leading Muffle, Tube, Vacuum, and CVD systems, all fully customizable to integrate continuous gas flow for your specific R&D needs. Backed by expert manufacturing, our high-temp furnaces ensure your data reflects true material performance—not environmental interference.

Ready to optimize your testing setup? Contact KINTEK today for a customized solution.

Visual Guide

References

- Zubin Chacko, Afsaneh Rabiei. A Study on Thermal Expansion and Thermomechanical Behavior of Composite Metal Foams. DOI: 10.1002/adem.202402871

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a high-pressure autoclave with a PTFE liner facilitate GLC synthesis? Ensure Purity and Safety

- Why is a vacuum drying oven used for BC-FeOOH biochar? Protect Reactivity and Prevent Particle Aggregation

- How does a high-temperature sintering furnace influence ZnO nanotube sensors? Unlock Peak Sensitivity and Stability

- How do laboratory high-temperature resistance furnaces simulate industrial production processes for 01YUT steel?

- What is a crucible furnace used for? Achieve Pure, Controlled Melts for Non-Ferrous Metals

- Why is a high-precision furnace required for Li22Sn5 synthesis? Ensure Pure-Phase Alloy Stability

- What is the use of dental ceramic? Achieve Lifelike, Durable, and Biocompatible Restorations

- What are the typical applications of drying ovens? Essential Uses in Labs and Industry