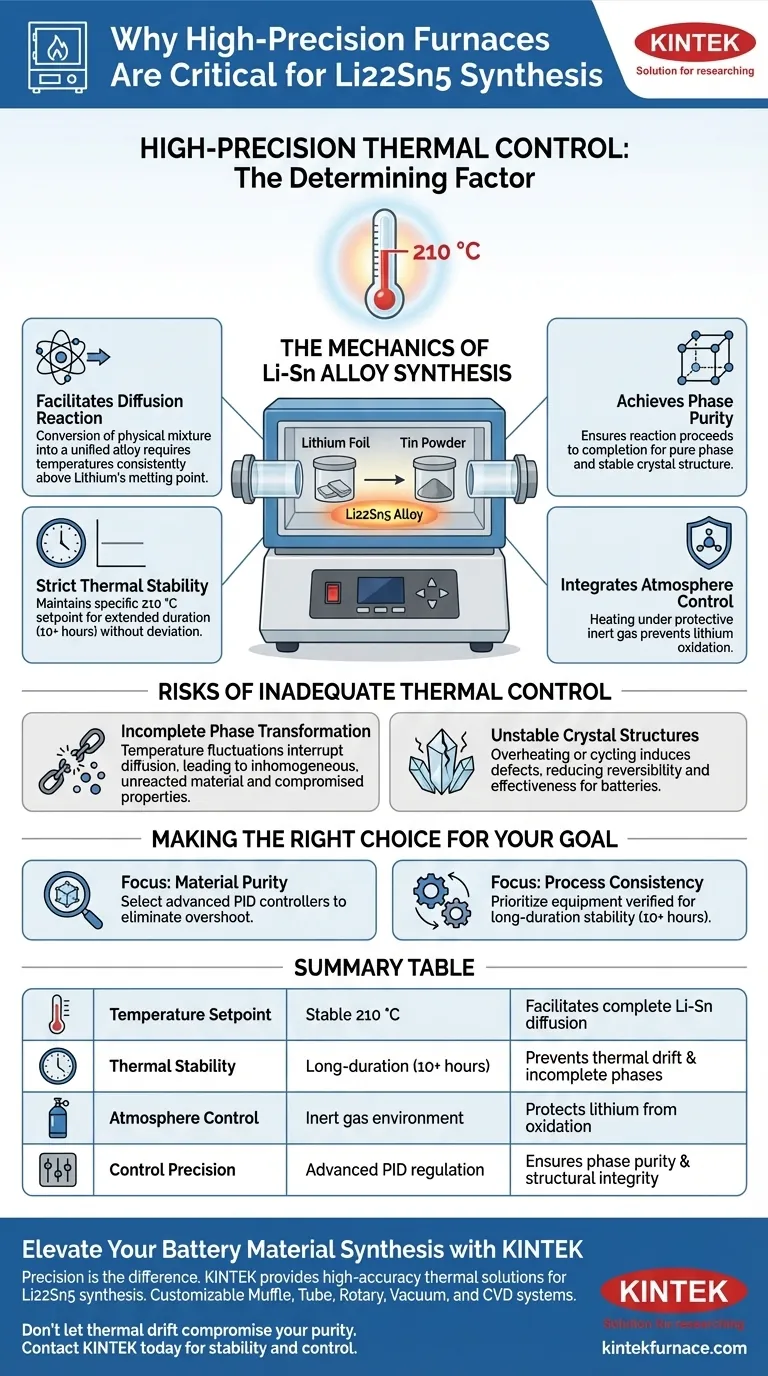

High-precision thermal control is the determining factor in the successful synthesis of Li22Sn5 deep lithiated alloys. To achieve a complete diffusion reaction between lithium foil and tin powder, the laboratory furnace must maintain a highly stable temperature around 210 °C for extended periods, ensuring the formation of a pure, stable crystal structure essential for battery performance.

Precise temperature regulation is not merely about heating; it is about sustaining the specific thermodynamic conditions required to transform raw lithium and tin into a reversible, pure-phase alloy suitable for energy storage.

The Mechanics of Li-Sn Alloy Synthesis

Facilitating the Diffusion Reaction

The synthesis of Li22Sn5 relies on a delicate fusion heat treatment process.

To convert the physical mixture of lithium foil and tin powder into a unified alloy, the atoms must undergo significant diffusion.

This reaction is only possible when the material is held consistently above the melting point of lithium.

Maintaining Strict Thermal Stability

The process requires the furnace to hold a specific setpoint, generally around 210 °C.

This temperature must be maintained without deviation for an extended duration, often lasting up to 10 hours.

High-precision equipment is necessary to prevent thermal drift over these long processing times.

Achieving Phase Purity

The ultimate objective is to create an alloy with a pure phase and a stable crystal structure.

precise thermal environment ensures that the reaction proceeds to completion, avoiding intermediate or unstable phases.

This structural integrity is what allows the material to function as a reliable and reversible lithium source.

Integrating Atmosphere Control

High-end furnaces designed for this synthesis also manage the atmospheric environment.

The heating process must occur under a protective inert atmosphere to prevent the lithium from oxidizing.

The furnace's ability to maintain temperature uniformity while housing an inert gas environment is critical for sample protection.

Risks of Inadequate Thermal Control

Incomplete Phase Transformation

If the furnace temperature fluctuates or drops below the critical threshold, the diffusion reaction will be interrupted.

This leads to an inhomogeneous material where the lithium and tin have not fully reacted.

Such inconsistency compromises the electrochemical properties of the final product.

Unstable Crystal Structures

Overheating or rapid thermal cycling can induce structural defects within the alloy.

Just as with other sensitive alloys, minor deviations can lead to drastic changes in phase content ratios.

An unstable crystal structure reduces the reversibility of the lithium source, rendering it less effective for battery applications.

Making the Right Choice for Your Goal

To ensure the successful synthesis of Li22Sn5, your equipment choice should align with your specific research or production needs.

- If your primary focus is Material Purity: Select a furnace with advanced PID controllers to eliminate temperature overshoot and ensure a homogeneous pure phase.

- If your primary focus is Process Consistency: Prioritize equipment verified for long-duration stability (10+ hours) to guarantee the diffusion reaction reaches completion every time.

Absolute thermal precision during the synthesis stage is the foundation for creating high-performance, reversible battery materials.

Summary Table:

| Feature | Requirement for Li22Sn5 Synthesis | Impact on Final Product |

|---|---|---|

| Temperature Setpoint | Stable 210 °C | Facilitates complete Li-Sn diffusion |

| Thermal Stability | Long-duration (10+ hours) | Prevents thermal drift and incomplete phases |

| Atmosphere Control | Inert gas environment | Protects lithium from oxidation |

| Control Precision | Advanced PID regulation | Ensures phase purity and structural integrity |

Elevate Your Battery Material Synthesis with KINTEK

Precision is the difference between a failed reaction and a high-performance reversible lithium source. KINTEK provides the high-accuracy thermal solutions required for sensitive processes like Li22Sn5 alloy synthesis. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific temperature and atmosphere requirements.

Don't let thermal drift compromise your material purity. Contact KINTEK today to discover how our laboratory furnaces can provide the stability and control your research demands.

Visual Guide

References

- Cheng Lu, Yue Ma. A lightweight, Li supplementary and lithiophilic interface enables anode-less lithium metal battery prototyping. DOI: 10.1039/d5eb00042d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does crucible base spalling affect nickel-base superalloys? Prevent Catastrophic Fatigue and Material Impurity

- Why is an industrial electric furnace with precise cooling control necessary in lead-bismuth alloy enrichment?

- Why is a vacuum drying oven required for processing MXene solutions and NPC@MoS2 nanostructures? Key Benefits Revealed

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- What role does the high-temperature boiling step play in rice husk silica conversion? Boost Your Extraction Yields

- How does the thermal field length impact YAG fiber dip coatings? Achieve Uniform, Bead-Free Films

- Why is immediate water quenching required for CuAlMn alloys? Master Phase Retention in Shape Memory Alloys

- What are the key advantages of using electric furnaces across industries? Boost Efficiency and Precision in Your Processes