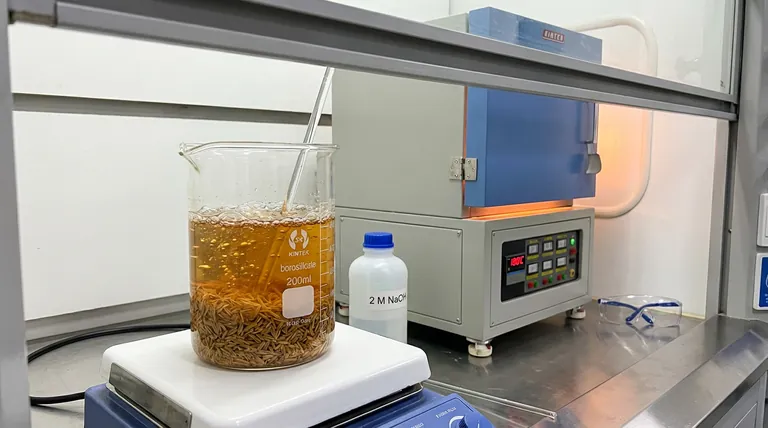

The high-temperature boiling step acts as the critical chemical trigger for extracting silica from rice husks. By heating the husks in a 2 M sodium hydroxide solution, you initiate a reaction that dissolves the solid silica components, converting them into a soluble sodium silicate solution.

The combination of heat and high alkalinity serves a dual purpose: it strips away the organic lignin barriers and drives the chemical conversion of agricultural waste into a usable industrial liquid.

The Mechanics of Extraction

Breaking Down the Protective Layer

Rice husks are naturally resilient structures. To access the silica within, you must first bypass their outer defenses.

The high-temperature boiling process creates a strong alkaline environment. This environment aggressively degrades the protective lignin layer that binds the husk structure together.

By breaking this organic seal, the solution exposes the underlying silica to the chemical reactants.

The Chemical Transformation

Once the lignin barrier is compromised, the core chemical reaction begins.

The silica components in the husk react directly with the alkali (sodium hydroxide). This reaction transforms the silica from a solid, insoluble state into soluble sodium silicate.

This phase is the defining moment where the material transitions from solid agricultural waste to a liquid industrial precursor.

Understanding the Trade-offs

Time and Energy Requirements

The primary reference notes that this process requires heating for an "extended period."

While effective, this indicates that the process is energy-intensive. You cannot rush the dissolution; the solution must be maintained at temperature long enough for the lignin to fully break down and the silica to dissolve completely.

Concentration Sensitivity

The process relies specifically on a 2 M sodium hydroxide solution.

If the concentration is too low, the solution may fail to penetrate the lignin layer effectively. This would leave silica trapped in the solid husk, resulting in a low yield of sodium silicate.

Making the Right Choice for Your Goal

To maximize the efficiency of your extraction process, consider the following key drivers:

- If your primary focus is yield: Ensure the boiling duration is sufficient to completely degrade the lignin layer, as partially processed husks will retain valuable silica.

- If your primary focus is process consistency: Strictly monitor the sodium hydroxide concentration at 2 M, as fluctuations here will directly alter the solvency power of the solution.

Mastering the variable of time against alkalinity is the key to efficient sodium silicate production.

Summary Table:

| Process Variable | Role / Function | Key Impact |

|---|---|---|

| High-Temp Boiling | Chemical Trigger | Accelerates lignin breakdown and silica dissolution |

| 2 M Sodium Hydroxide | Alkaline Reactant | Transforms solid silica into soluble sodium silicate |

| Extended Duration | Kinetic Requirement | Ensures complete penetration of resilient husk structures |

| Lignin Degradation | Barrier Removal | Exposes underlying silica to the chemical solution |

Precision Solutions for Your Extraction Research

Consistency in agricultural waste conversion requires absolute control over temperature and chemical kinetics. KINTEK provides the high-performance laboratory equipment necessary to master these variables.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab high-temp needs. Whether you are scaling up sodium silicate production or refining lignin degradation protocols, our furnaces deliver the uniform heating essential for high-yield results.

Contact KINTEK today to optimize your extraction workflow!

References

- Shengwang Yuan, Yunhai Ma. A Comparative Study on Rice Husk, as Agricultural Waste, in the Production of Silica Nanoparticles via Different Methods. DOI: 10.3390/ma17061271

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do elliptical mirrors function to create a horizontal temperature field in an optical Floating-Zone furnace?

- How does a stable constant temperature environment influence the structural development of LDHs during aging?

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- How do sputtering systems and lift-off processes interact? Master Micro-Device Fabrication for ST-FMR Measurements

- What are the benefits of using graphite or stainless steel crucibles for Rubidium Chloride? Ensure Maximum Purity

- What is the function of controlled hot air flow treatment in ZnO drying? Master Surface Flatness and Stress Reduction

- Why is argon particularly attractive for industrial applications? Unlock Cost-Effective Purity and Stability

- What are the advantages of solution combustion synthesis? Optimize (MnFeNiCoX)3O4 High-Entropy Oxide Catalyst Production