In modern dentistry, dental ceramics are used to create highly aesthetic, durable, and biocompatible restorations that mimic the appearance and function of natural teeth. They are the material of choice for applications such as crowns, bridges, veneers, and inlays, valued for their ability to blend seamlessly into a patient's smile while withstanding the forces of chewing.

The core value of dental ceramics is not just one feature, but their unique combination of properties. They offer superior aesthetics that closely match natural tooth enamel, are highly biocompatible, and possess thermal characteristics similar to teeth, making them ideal for restorations where both appearance and biological safety are paramount.

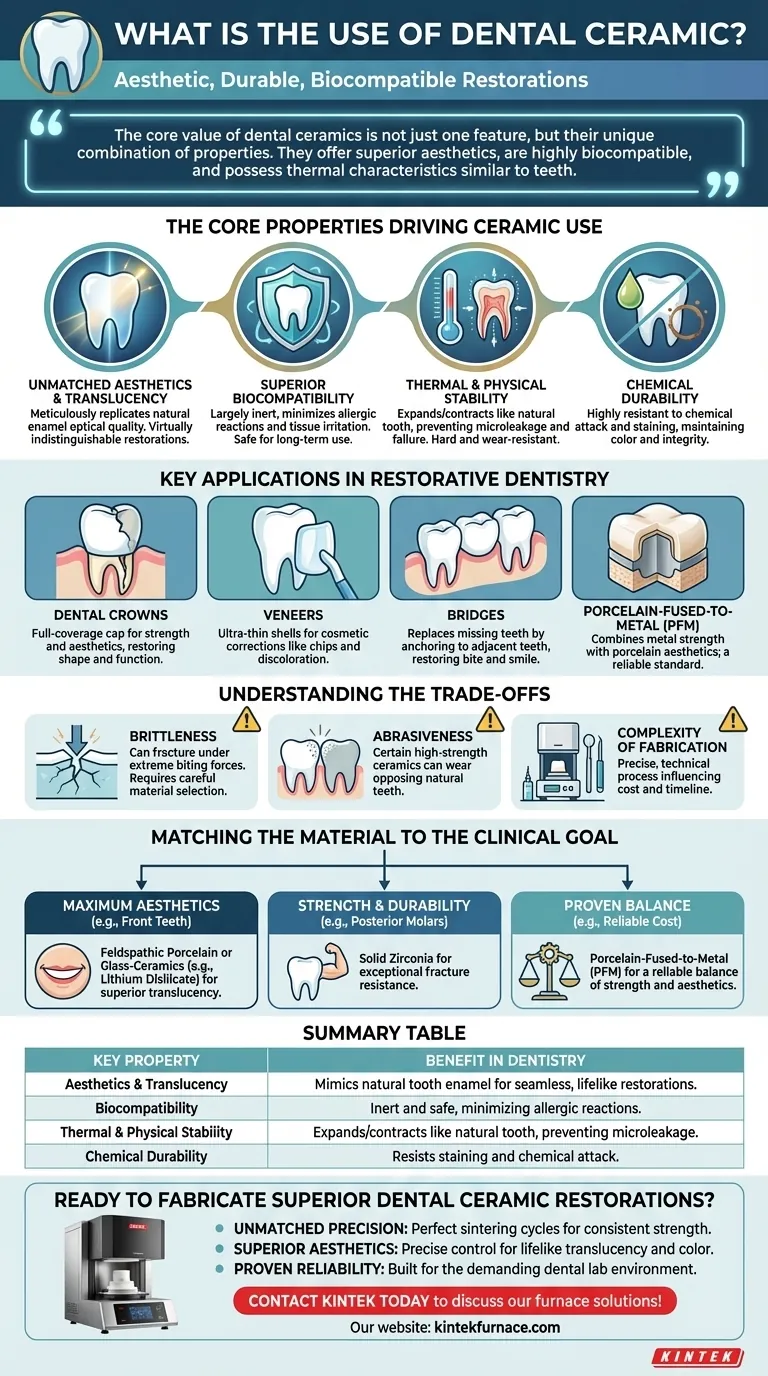

The Core Properties Driving Ceramic Use

The widespread adoption of ceramics in dentistry is a direct result of their specific material characteristics. These properties solve the primary challenges of replacing or repairing tooth structure.

Unmatched Aesthetics and Translucency

Ceramics possess an optical quality, including translucency and color, that can be meticulously controlled to replicate natural enamel. This allows for restorations that are virtually indistinguishable from the surrounding teeth, a critical factor for patient satisfaction, especially in the front of the mouth.

Superior Biocompatibility

Dental ceramics are largely inert, meaning they do not corrode or release substances into the body. This excellent biocompatibility minimizes the risk of allergic reactions or local tissue irritation, making them one of the safest materials for long-term placement in the oral environment.

Thermal and Physical Stability

Ceramics expand and contract with temperature changes at a rate very similar to natural tooth structure. This prevents stress at the margin between the restoration and the tooth, reducing the risk of microleakage and failure over time. They are also very hard and resistant to wear.

Chemical Durability

Unlike other materials, ceramics are highly resistant to chemical attack from acids in the mouth or staining from foods and drinks like coffee, tea, and red wine. This ensures the restoration maintains its color and integrity for many years.

Key Applications in Restorative Dentistry

The properties of ceramics make them suitable for a wide range of restorative procedures, from single-tooth repairs to replacing multiple missing teeth.

Dental Crowns

A crown is a full-coverage cap placed over a damaged tooth. Ceramic crowns are a preferred option for their ability to provide both strength and excellent aesthetics, restoring the tooth's original shape, size, and function.

Veneers

Veneers are ultra-thin shells of ceramic bonded to the front surface of teeth to correct cosmetic issues like chips, gaps, or discoloration. Because aesthetics are the primary goal, the optical properties of porcelain and other glass-ceramics make them the ideal material.

Bridges

A dental bridge is used to replace one or more missing teeth by anchoring to the adjacent natural teeth. All-ceramic or ceramic-fused-to-metal bridges are common solutions that restore the patient's bite and smile.

Porcelain-Fused-to-Metal (PFM)

These restorations combine the strength of a metal substructure with the aesthetics of an overlying layer of porcelain. For decades, PFM crowns and bridges have been a reliable standard in dentistry, offering a proven balance of durability and appearance.

Understanding the Trade-offs

While highly effective, dental ceramics are not without limitations. Understanding these trade-offs is crucial for making the correct clinical decision.

Brittleness as a Limiting Factor

Despite their hardness, some types of ceramics can be brittle and may fracture under extreme biting forces. This is why material selection is critical, with stronger ceramics like zirconia often being used for posterior teeth (molars) that endure higher stress.

Abrasiveness to Opposing Teeth

Certain high-strength ceramics, particularly some forms of zirconia, can be more abrasive than natural enamel. Over time, this can cause wear on the opposing natural teeth, a factor that must be considered during treatment planning.

Complexity of Fabrication

Creating a ceramic restoration is a precise and technical process. It requires taking impressions, laboratory fabrication, and often multiple firing cycles in a specialized furnace. This complexity can influence the overall cost and timeline of the treatment compared to simpler procedures.

Matching the Material to the Clinical Goal

The term "ceramic" encompasses a range of materials with different strengths and aesthetic qualities. The right choice depends entirely on the specific goal of the restoration.

- If your primary focus is maximum aesthetics (e.g., front teeth): Feldspathic porcelain or glass-ceramics like lithium disilicate are the top choices due to their superior translucency and lifelike appearance.

- If your primary focus is strength and durability (e.g., posterior molars): Solid zirconia is the ideal material, offering exceptional fracture resistance to withstand heavy chewing forces.

- If your primary focus is a proven balance of strength and cost-effectiveness: Porcelain-fused-to-metal (PFM) restorations remain a highly reliable and predictable option for crowns and bridges.

Ultimately, selecting the right dental ceramic involves a careful assessment of the clinical need, balancing the demands of strength, aesthetics, and long-term biological function.

Summary Table:

| Key Property | Benefit in Dentistry |

|---|---|

| Aesthetics & Translucency | Mimics natural tooth enamel for seamless, lifelike restorations. |

| Biocompatibility | Inert and safe for long-term oral use, minimizing allergic reactions. |

| Thermal & Physical Stability | Expands/contracts like natural tooth, preventing microleakage and failure. |

| Chemical Durability | Resists staining from food/drinks and chemical attack from oral acids. |

Ready to Fabricate Superior Dental Ceramic Restorations?

Precision and consistency are paramount in dental lab work. KINTEK's advanced high-temperature furnaces are engineered to deliver the exact thermal profiles required for flawless sintering and crystallization of all ceramic materials—from high-strength zirconia to aesthetic lithium disilicate.

Why choose KINTEK for your dental lab furnace?

- Unmatched Precision: Achieve perfect sintering cycles for consistent, high-strength results with every restoration.

- Superior Aesthetics: Our precise temperature control ensures optimal crystallization for lifelike translucency and color in porcelain and glass-ceramics.

- Proven Reliability: Built for the demanding environment of a dental lab, our furnaces ensure maximum uptime and productivity.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your unique production requirements.

Contact KINTEK today to discuss how our furnace solutions can enhance the quality and efficiency of your ceramic restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations