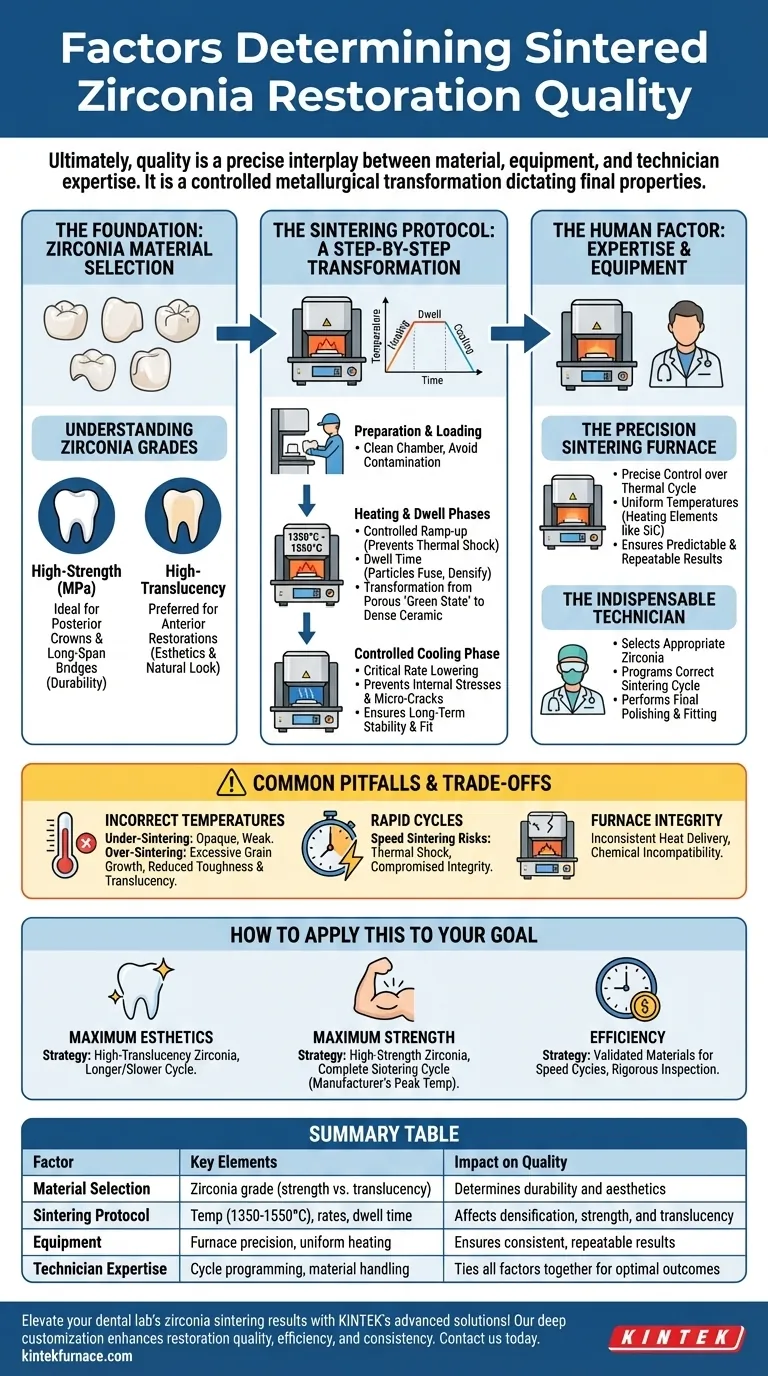

Ultimately, the quality of a sintered zirconia restoration is determined by a precise interplay between the selected material, the sophistication of the equipment, and the expertise of the technician executing the process. A successful outcome is not the result of a single factor but the culmination of a controlled protocol where every variable, from the initial material choice to the final cooling rate, is meticulously managed.

Sintering is far more than simply heating a restoration in a furnace. It is a controlled metallurgical transformation that dictates the final physical properties of the zirconia, including its strength, translucency, and marginal fit. Achieving excellence requires mastering the variables of this thermal process.

The Foundation: Zirconia Material Selection

Before the sintering process even begins, the choice of material sets the stage for the final outcome. Not all zirconia is created equal, and the selection must align with the clinical demands of the restoration.

Understanding Zirconia Grades

Zirconia blanks are available in different formulations, primarily balancing strength (measured in MPa) and translucency.

High-strength zirconia is ideal for posterior crowns and long-span bridges where durability is paramount. High-translucency zirconia is preferred for anterior restorations where esthetics and a natural appearance are the primary goals.

The Sintering Protocol: A Step-by-Step Transformation

The sintering cycle is a precise thermal journey that transforms the soft, porous "green state" zirconia into a dense, strong ceramic. Each stage has a direct impact on quality.

Stage 1: Preparation and Loading

The milled restoration is carefully placed into the sintering furnace. It is critical to ensure the chamber is clean, as any debris or contaminants can discolor the zirconia during the high-temperature cycle.

Stage 2: The Heating and Dwell Phases

The furnace gradually heats the restoration to a target temperature, typically between 1350°C and 1550°C. A slow, controlled ramp-up prevents thermal shock and potential fractures.

Once at the peak temperature, the restoration "dwells" or "soaks" for a specific duration. During this critical phase, the individual zirconia particles fuse together, eliminating porosity and causing the material to shrink and densify into its final, robust state.

Stage 3: The Controlled Cooling Phase

Cooling is just as critical as heating. The furnace must lower the temperature at a controlled rate. Cooling too quickly can introduce internal stresses, leading to micro-cracks and compromising the long-term stability and fit of the restoration.

Understanding the Trade-offs and Common Pitfalls

Deviations from an ideal protocol can significantly compromise the final quality. Understanding these risks is key to producing consistent results.

The Risk of Incorrect Temperatures

An incorrect sintering temperature is a primary cause of failure. Under-sintering results in an opaque, weak restoration with poor physical properties. Over-sintering can cause excessive grain growth, which can reduce fracture toughness and negatively impact translucency.

The Dangers of Rapid Cycles

While "speed sintering" cycles offer efficiency, they must be used with compatible materials and a deep understanding of the risks. Abbreviated heating and cooling phases increase the potential for thermal shock, which can compromise the marginal integrity and structural soundness of the restoration.

The Impact of Furnace Integrity

The quality of the furnace itself is paramount. It must be capable of maintaining uniform, accurate temperatures. The heating elements, often made of durable silicon carbide (SiC), must be in good condition to ensure chemical compatibility and consistent heat delivery.

The Human Factor: Expertise and Equipment

Beyond the material and the process lies the crucial role of the operator and their tools.

The Precision Sintering Furnace

High-quality outcomes demand advanced equipment. A modern sintering furnace provides precise control over every parameter of the thermal cycle, from heating rates to dwell times and cooling profiles, ensuring predictable and repeatable results.

The Indispensable Technician

A skilled technician's expertise is the deciding factor that ties everything together. They are responsible for selecting the appropriate zirconia, programming the correct sintering cycle for that specific material, and performing the final polishing and fitting that ensures optimal patient compatibility.

How to Apply This to Your Goal

Your clinical objective should guide your approach to the sintering process.

- If your primary focus is maximum esthetics: Utilize a high-translucency zirconia and a longer, slower sintering cycle to fully develop its optical properties.

- If your primary focus is maximum strength: Select a high-strength zirconia and ensure a complete sintering cycle at the manufacturer's recommended peak temperature to achieve full densification.

- If your primary focus is efficiency: Use materials specifically validated for speed sintering cycles, but remain aware of the potential trade-offs and rigorously inspect restorations for any signs of compromised integrity.

Mastering these factors is the key to transforming a milled blank into a predictable, durable, and esthetic final restoration.

Summary Table:

| Factor | Key Elements | Impact on Quality |

|---|---|---|

| Material Selection | Zirconia grade (strength vs. translucency) | Determines durability and aesthetics |

| Sintering Protocol | Temperature (1350-1550°C), heating/cooling rates, dwell time | Affects densification, strength, and translucency |

| Equipment | Furnace precision, uniform heating, element condition | Ensures consistent, repeatable results |

| Technician Expertise | Cycle programming, material handling, final fitting | Ties all factors together for optimal outcomes |

Elevate your dental lab's zirconia sintering results with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing restoration quality, efficiency, and consistency. Contact us today to discuss how our tailored furnace solutions can meet your specific goals and drive success in your dental applications!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab