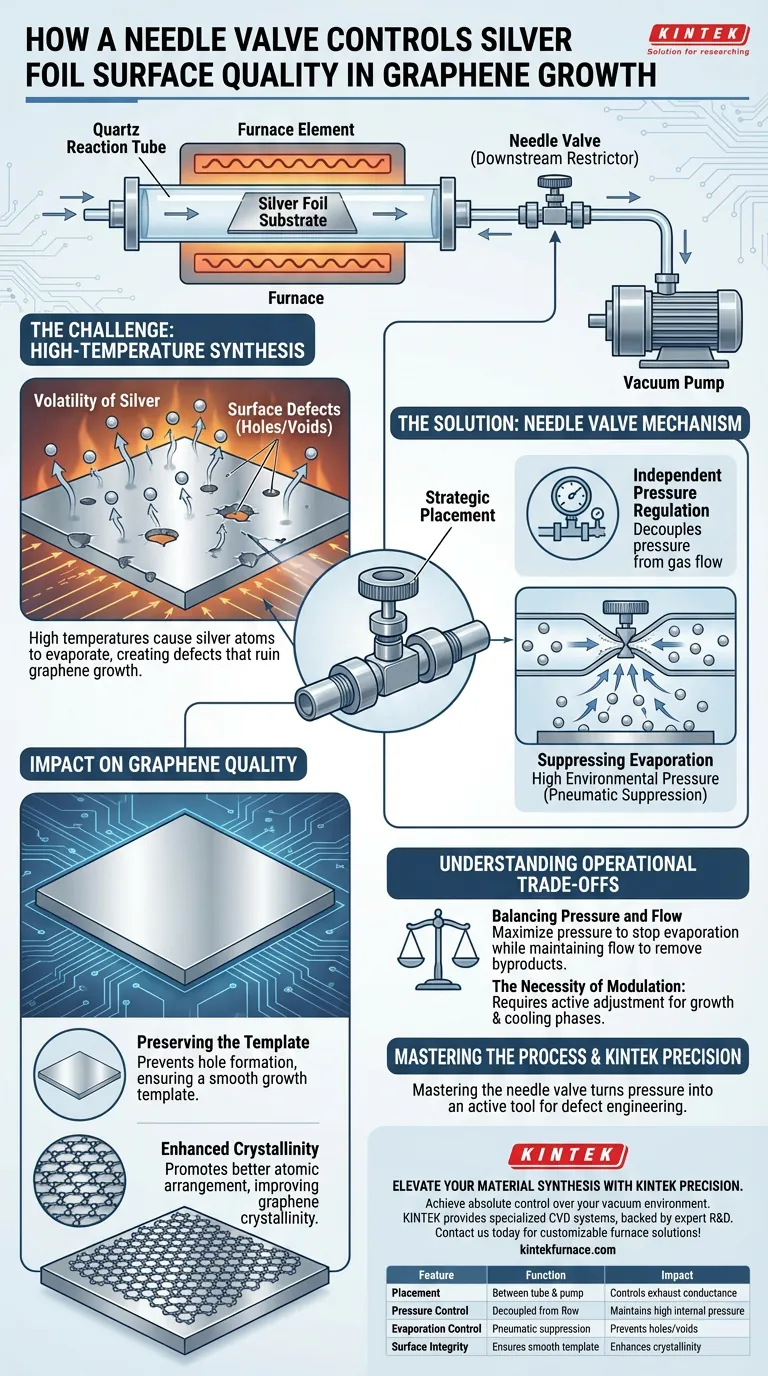

The needle valve serves as a precise regulator of environmental pressure independent of gas flow rates. Installed between the quartz reaction tube and the vacuum pump, it restricts the exhaust path to maintain higher internal pressures during the critical growth and cooling phases. This elevated pressure physically suppresses the evaporation of silver atoms at high temperatures, effectively preventing the formation of holes on the substrate and ensuring a pristine surface for high-quality graphene synthesis.

High-temperature synthesis often causes silver substrates to evaporate, creating surface defects that ruin graphene growth. The needle valve solves this by decoupling pressure control from gas flow, allowing you to maintain high environmental pressure that locks silver atoms in place to preserve the foil's integrity.

The Challenge of High-Temperature Synthesis

The Volatility of Silver

Graphene growth requires significant thermal energy to catalyze the reaction. However, at these elevated temperatures, silver atoms on the substrate surface become highly volatile.

Formation of Surface Defects

Without intervention, this volatility leads to the excessive evaporation of silver atoms. As atoms leave the lattice, they create voids and holes on the foil surface, degrading the template required for continuous graphene layers.

The Mechanism of the Needle Valve

Strategic Placement

The needle valve is positioned specifically between the quartz tube (the reaction chamber) and the vacuum pump. This location is critical for its function as a downstream restrictor.

Independent Pressure Regulation

The primary function of this component is to modulate the vacuum pressure without altering the input gas flow rates. By adjusting the valve opening, you can decouple the exhaust rate from the intake rate.

Suppressing Evaporation

Constricting the valve increases the environmental pressure within the chamber. This high-pressure environment acts as a pneumatic suppression system, preventing the silver atoms from sublimating and forcing them to remain part of the solid substrate.

Impact on Graphene Quality

Preserving the Template

By preventing the formation of holes on the silver foil, the needle valve ensures the substrate remains smooth and continuous. This is the foundational requirement for epitaxial growth.

Enhanced Crystallinity

A stable, defect-free silver surface promotes better atomic arrangement of carbon atoms. Consequently, the graphene grown under these controlled pressure conditions exhibits significantly improved crystallinity.

Understanding Operational Trade-offs

The Necessity of Modulation

The needle valve is not a "set and forget" component; it requires active modulation. It must be adjusted to suit the specific requirements of both the growth and cooling stages.

Balancing Pressure and Flow

While the goal is high pressure, the system still requires flow to remove byproducts. The trade-off lies in finding the precise valve position that maximizes pressure to stop evaporation while maintaining just enough conductance for the system to function.

Making the Right Choice for Your Goal

To maximize the effectiveness of the needle valve in your setup, consider the following operational priorities:

- If your primary focus is preventing substrate damage: Prioritize restricting the valve opening during peak temperatures to maximize suppression of silver evaporation.

- If your primary focus is graphene crystallinity: Ensure the valve maintains consistent high pressure throughout the cooling stage to prevent late-stage surface degradation.

Mastering the needle valve transforms chamber pressure from a passive environmental variable into an active tool for defect engineering.

Summary Table:

| Feature | Function in Graphene Growth | Impact on Silver Foil |

|---|---|---|

| Placement | Between reaction tube and vacuum pump | Controls exhaust conductance |

| Pressure Control | Decoupled from gas flow rates | Maintains high internal pressure |

| Evaporation Control | Pneumatic suppression of atoms | Prevents hole formation and voids |

| Surface Integrity | Ensures a smooth growth template | Enhances graphene crystallinity |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect graphene layer requires more than just high temperatures—it demands absolute control over your vacuum environment. KINTEK provides the specialized equipment needed to master complex CVD processes.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique research or production needs. Whether you are looking to suppress substrate evaporation or optimize crystalline growth, our engineering team is ready to support your lab's success.

Ready to refine your growth process? Contact us today to explore our customizable furnace solutions!

Visual Guide

References

- Hikaru Iwatani, Fumihiko Maeda. Graphene Synthesis on Silver Foil by Chemical Vapor Deposition Using Ethanol. DOI: 10.1380/ejssnt.2025-026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the technical value of using a vacuum drying oven? Master Platinum Catalyst Precision and Activity

- What is the purpose of the sulfidation treatment process? Enhance Reactor Performance with DMDS Passivation

- What role does a high-temperature annealing furnace play in the preparation of AAO substrates? Enhance Pore Regularity

- What role does activation treatment play in converting PPS waste? Unlock High-Performance Energy Storage Pores

- What is the significance of an in-situ high-temperature heating stage? Unlock Real-Time Crystal Structure Insights

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the function of industrial electric furnaces in EN AW-6082 preparation? Master Aluminum Heat Treatment

- What is the temperature of a sintering furnace? From 1100°C to 2200°C+ for Your Material