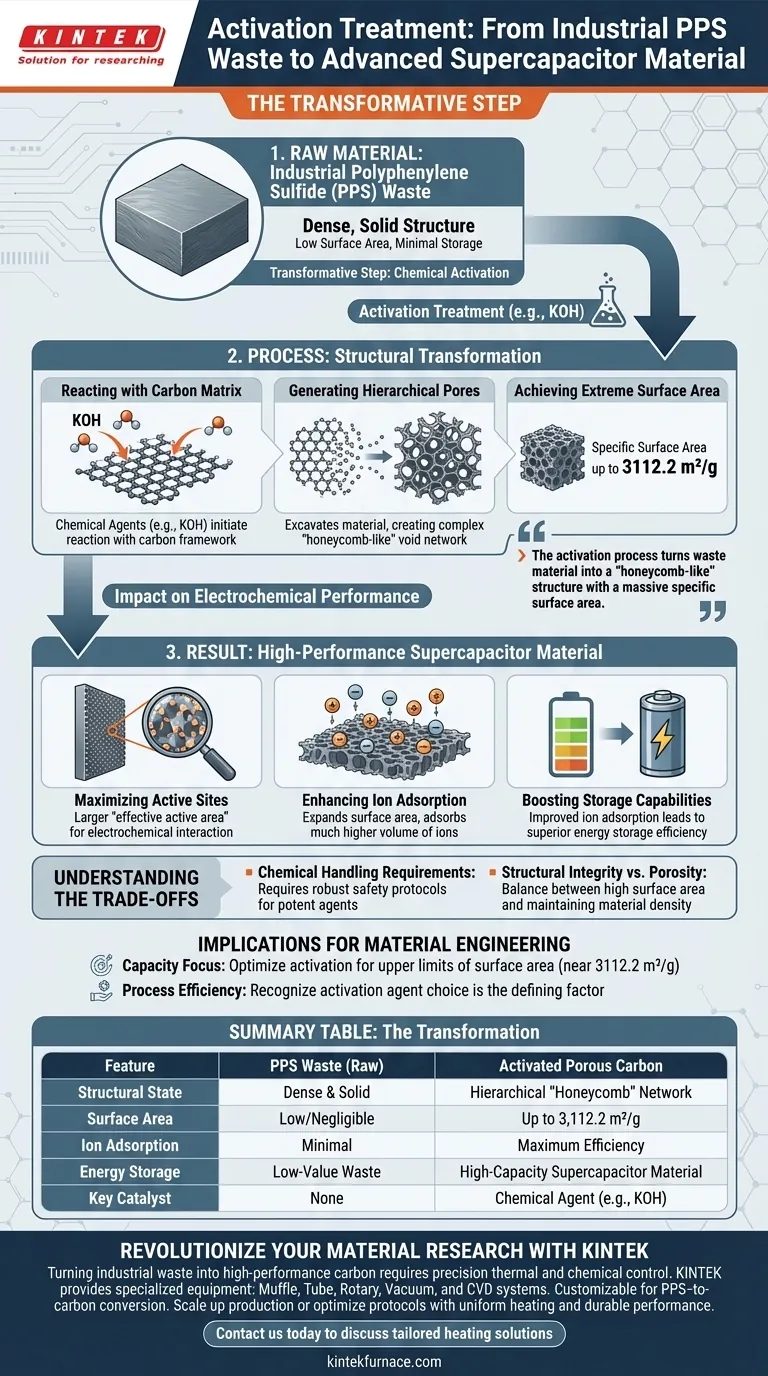

Activation treatment is the transformative step that converts dense industrial Polyphenylene Sulfide (PPS) waste into highly functional supercapacitor material. By employing chemical agents such as potassium hydroxide (KOH), this treatment triggers a reaction that radically alters the carbon’s internal architecture, creating the porosity required for energy storage.

The activation process turns waste material into a "honeycomb-like" structure with a massive specific surface area. This physical transformation is the direct cause of enhanced ion adsorption and superior energy storage capabilities.

The Mechanism of Structural Transformation

Reacting with the Carbon Matrix

The core function of activation treatment is not merely cleaning the material, but chemically attacking it. When agents like KOH are introduced to the PPS waste, they initiate a chemical reaction with the carbon framework.

Generating Hierarchical Pores

This reaction excavates the material, resulting in a "hierarchical" porous carbon structure. Instead of a solid block, the material develops a complex, honeycomb-like network of voids and channels.

Achieving Extreme Surface Area

The primary metric of success for this treatment is specific surface area. The activation process is capable of increasing this area to extreme levels, reaching as high as 3112.2 m²/g.

Impact on Electrochemical Performance

Maximizing Active Sites

The dramatic increase in surface area creates a significantly larger "effective active area" for the electrode. Every new pore created by the activation treatment serves as a potential site for electrochemical interaction.

Enhancing Ion Adsorption

Supercapacitors rely on ions clinging to the surface of the electrode. By expanding the available surface area through activation, the material can adsorb a much higher volume of ions.

Boosting Storage Capabilities

The direct result of improved ion adsorption is enhanced storage capacity. The activation treatment effectively unlocks the potential of the PPS waste, allowing it to store energy far more efficiently than the untreated raw material.

Understanding the Trade-offs

Chemical Handling Requirements

While agents like KOH are highly effective at creating pores, they are potent chemicals. Utilizing this method requires robust safety protocols and chemical management strategies to handle the corrosive nature of the activation agents.

Structural Integrity vs. Porosity

There is often a balance between creating high surface area and maintaining material density. While the text highlights an impressive 3112.2 m²/g surface area, pushing porosity to extreme limits can sometimes affect the volumetric density of the final electrode material.

Implications for Material Engineering

The transformation of PPS waste proves that industrial byproducts can be upcycled into premium energy materials.

- If your primary focus is capacity: Ensure the activation process is optimized to reach the upper limits of specific surface area (near 3112.2 m²/g) to maximize ion storage.

- If your primary focus is process efficiency: Recognize that the choice of activation agent (e.g., KOH) is the defining factor in achieving the necessary honeycomb structure.

Ultimately, the activation treatment is the bridge that turns low-value industrial waste into high-value, high-surface-area carbon for advanced energy storage.

Summary Table:

| Feature | PPS Waste (Raw) | Activated Porous Carbon |

|---|---|---|

| Structural State | Dense & Solid | Hierarchical "Honeycomb" Network |

| Surface Area | Low/Negligible | Up to 3,112.2 m²/g |

| Ion Adsorption | Minimal | Maximum Efficiency |

| Energy Storage | Low-Value Waste | High-Capacity Supercapacitor Material |

| Key Catalyst | None | Chemical Agent (e.g., KOH) |

Revolutionize Your Material Research with KINTEK

Turning industrial waste into high-performance carbon requires precision thermal and chemical control. KINTEK provides the specialized equipment needed to drive these transformations. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are customizable to meet the unique activation temperatures and atmospheres required for PPS-to-carbon conversion.

Whether you are scaling up supercapacitor production or optimizing laboratory protocols, our high-temperature furnaces ensure uniform heating and durable performance. Contact us today to discuss how our tailored heating solutions can enhance your laboratory's efficiency and material innovation.

Visual Guide

References

- Perseverance Dzikunu, Pedro Vilaça. Waste-to-carbon-based supercapacitors for renewable energy storage: progress and future perspectives. DOI: 10.1007/s40243-024-00285-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- What role does a closed pressure vessel play during the carbonation of gamma-C2S? Unlock Rapid Mineralization

- What role does an industrial resistance furnace play in 42CrMo/Cr5 heating? Ensure Forging Success with Precision.

- What factors should be considered when selecting a furnace based on material properties? Ensure Optimal Heat Treatment

- How does the thermal treatment enhance the mechanical properties of AZO and ZnO coatings? Boost Durability & Hardness

- What is the role of vacuum pressure impregnation equipment in Fe3O4 synthesis? Master Magnetic Wood Fiber Engineering

- What is the purpose of using a high-vacuum pump system for NiTi thin films? Ensure Pure Stoichiometry & Performance

- What is the technical purpose of the ball milling process for Ti12%Zr? Master Mechanical Activation & Alloying

- What is the purpose of high-purity argon in heat treating Al-Cu-Mn-Zr-V alloys? Protect Your Material Integrity