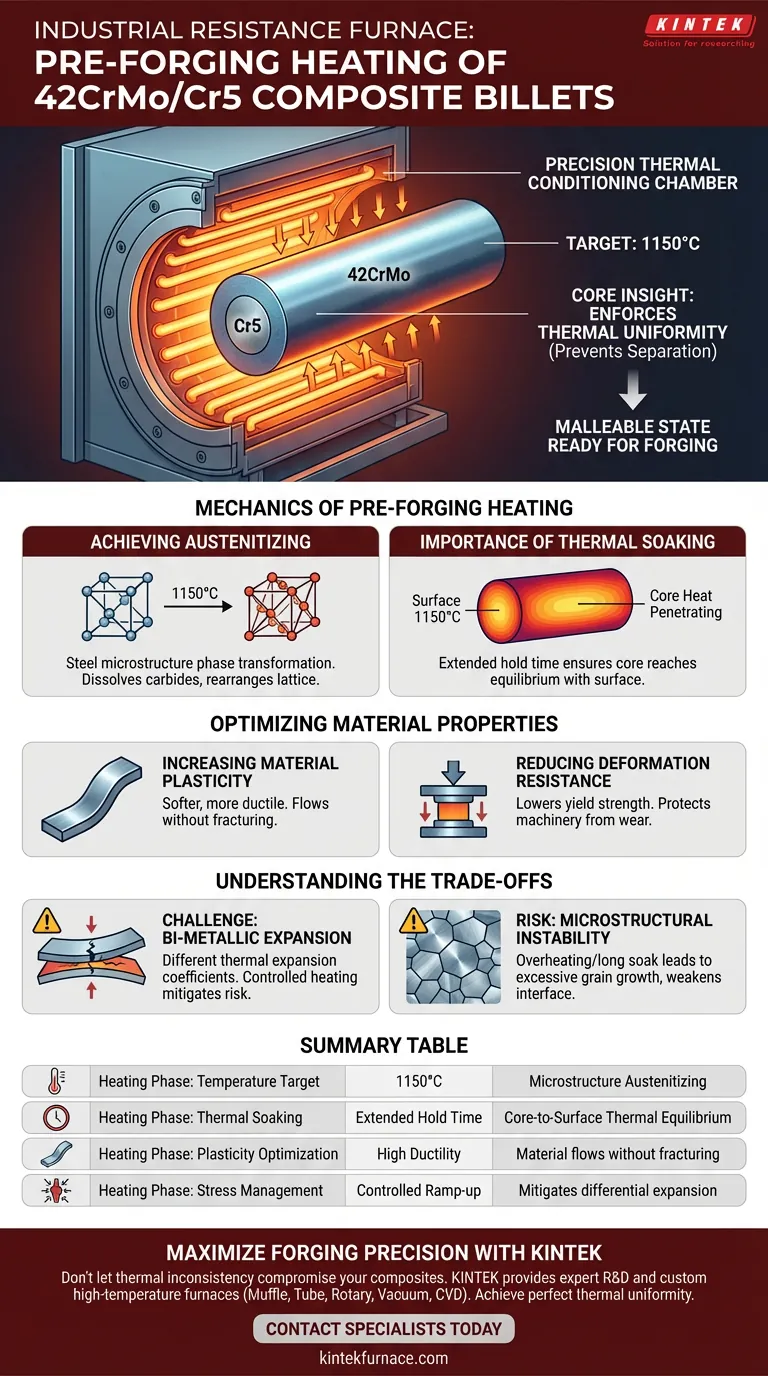

The industrial resistance furnace serves as a precision thermal conditioning chamber for 42CrMo/Cr5 composite billets. Its specific role is to gradually heat the sealed billets to a target temperature of 1150°C and maintain that thermal state for a defined duration. This controlled heating is the critical first step that transforms the rigid composite material into a malleable state ready for high-impact shaping.

Core Insight: The furnace’s primary function is not just to heat the metal, but to enforce thermal uniformity. By holding the billet at 1150°C, the process ensures that both the inner core and the outer composite layer reach the same austenitizing temperature, which is essential for preventing separation during the violence of the forging process.

The Mechanics of Pre-Forging Heating

Achieving the Austenitizing Target

The resistance furnace is calibrated to reach a specific operational temperature of 1150°C.

At this temperature, the steel microstructure undergoes a phase transformation known as austenitizing. This changes the crystal structure of the metal, dissolving carbides and preparing the atomic lattice for rearrangement.

The Importance of Thermal Soaking

Reaching 1150°C is not instantaneous; the furnace must maintain this temperature for an extended period.

This "soaking" phase is vital because heat penetrates from the outside in. Without an extended hold time, the surface might be at 1150°C while the core remains cooler. The resistance furnace ensures the thermal energy is distributed evenly throughout the entire volume of the billet.

Optimizing Material Properties

Increasing Material Plasticity

The primary outcome of this heating process is a drastic increase in plasticity.

By ensuring the 42CrMo/Cr5 composite reaches a uniform austenitizing state, the material becomes softer and more ductile. This allows the billet to flow into complex shapes without fracturing under the pressure of the forge.

Reducing Deformation Resistance

Cold or unevenly heated metal fights back against forging equipment.

The resistance furnace lowers the material's yield strength (deformation resistance). This protects the forging machinery from excessive wear and ensures that the force applied results in shaping the metal rather than bouncing off rigid spots.

Understanding the Trade-offs

The Challenge of Bi-Metallic Expansion

While the furnace provides heat, it must also manage the complexity of a composite material.

42CrMo and Cr5 are different metals with distinct thermal expansion coefficients. If the heating is too rapid or uncontrolled, the layers may expand at different rates. The controlled environment of an industrial resistance furnace mitigates this risk compared to faster, less precise heating methods.

The Risk of Microstructural Instability

Precision is required to avoid overheating.

While 1150°C is the target for plasticity, exceeding this temperature or soaking for too long can lead to excessive grain growth. This would degrade the mechanical properties of the final product, weakening the interface between the core and the composite layer.

Making the Right Choice for Your Goal

To maximize the effectiveness of the pre-forging heating process, consider the following operational priorities:

- If your primary focus is Dimensional Consistency: Ensure the furnace soaking time is sufficient for the core to reach thermal equilibrium with the surface, preventing internal resistance during forging.

- If your primary focus is Layer Adhesion: strictly monitor the 1150°C limit to ensure both materials austenitize without generating excessive thermal stress at the interface.

Proper thermal preparation in the resistance furnace is the single most important factor in determining whether a composite billet will forge successfully or fail under pressure.

Summary Table:

| Heating Phase | Target / Objective | Key Outcome |

|---|---|---|

| Temperature Target | 1150°C | Microstructure phase transformation (Austenitizing) |

| Thermal Soaking | Extended Hold Time | Core-to-surface thermal equilibrium |

| Plasticity Optimization | High Ductility | Material flows without fracturing during forging |

| Stress Management | Controlled Ramp-up | Mitigates differential expansion between 42CrMo & Cr5 |

Maximize Your Forging Precision with KINTEK

Don't let thermal inconsistency compromise your high-performance composites. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab and industrial high-temperature furnaces are fully customizable to meet your unique metallurgical needs.

Ready to achieve perfect thermal uniformity? Contact our specialists today to discover how our precision heating technology can enhance your material plasticity and reduce deformation resistance.

Visual Guide

References

- Ming Li, S.W. Xin. Interface Microstructure and Properties of 42CrMo/Cr5 Vacuum Billet Forged Composite Roll. DOI: 10.3390/ma18010122

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What reaction conditions are provided by stirring and heating equipment? Optimize Non-Aqueous Sol-Gel Synthesis

- What is the purpose of using a passivation system with diluted oxygen? Ensure Safe Catalyst Handling and Stability

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation

- How does the Flash Heating (FH) process impact the growth of REBCO films? Master Rapid Thermal Ramp Requirements

- What is the objective of coordinating mechanical stirring and heating for perovskite slurries? Achieve Homogeneity

- What is the function of a laboratory oven in ZnO processing? Optimize Precursor Drying & Prevent Agglomeration

- What challenges are associated with batch furnaces? Overcome Inefficiency and Quality Issues

- How do lab furnaces simulate fire environments for UHPFRC testing? Achieving ISO834 Standard Compliance