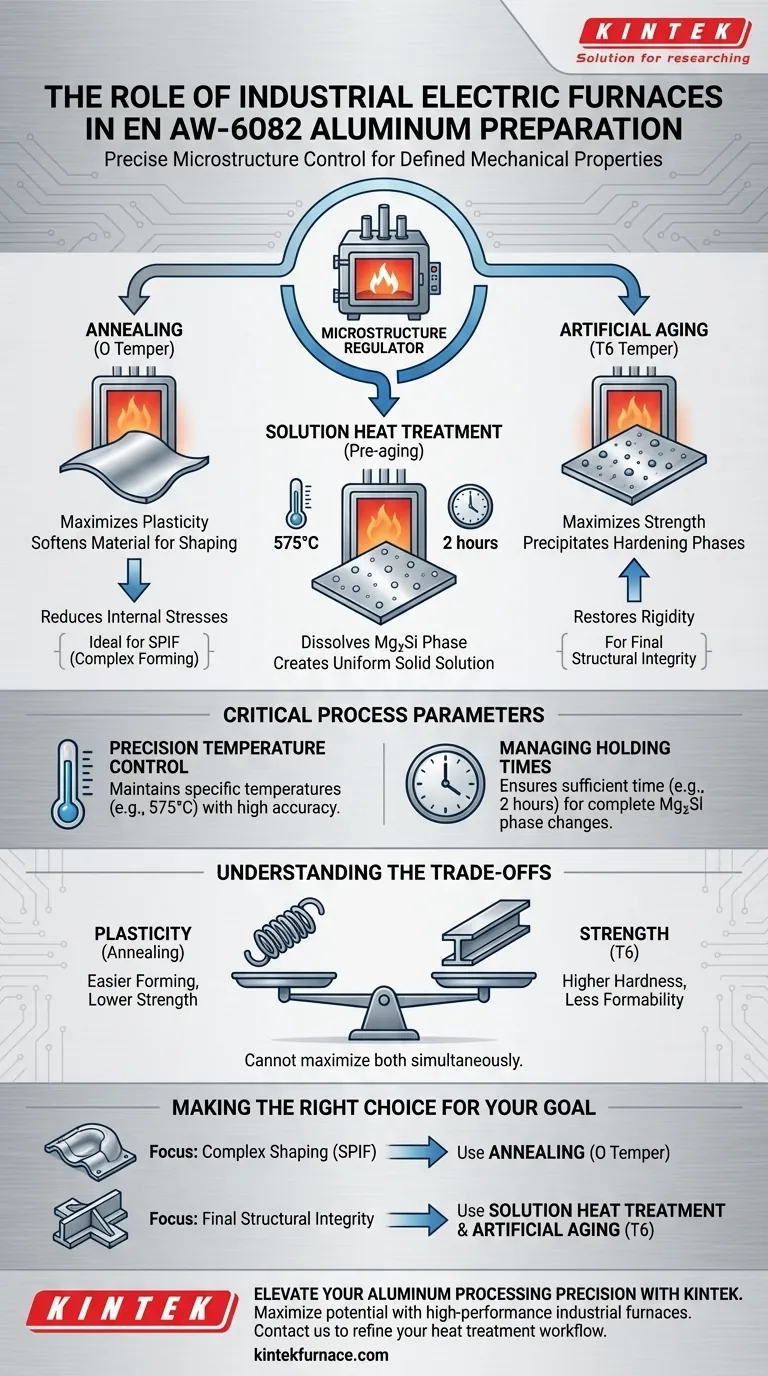

Industrial electric furnaces serve as the precise control mechanism for defining the mechanical properties of EN AW-6082 aluminum alloy sheets. Their primary function is to execute critical heat treatment cycles—specifically annealing, solution heat treatment, and artificial aging—which manipulate the alloy's internal structure. By maintaining exact temperatures and holding times, these furnaces prepare the material for demanding manufacturing techniques like Single Point Incremental Forming (SPIF).

The Core Objective The furnace does not simply heat the metal; it acts as a microstructure regulator. Its goal is to facilitate the dissolution or precipitation of the Mg2Si strengthening phase, allowing you to accurately dial in the specific hardness or plasticity required for your final application.

The Role of Microstructure Manipulation

Controlling the Mg2Si Phase

The defining characteristic of EN AW-6082 is its reliance on the magnesium silicide (Mg2Si) phase for strength.

The electric furnace is responsible for controlling the state of this phase. Depending on the temperature profile, the furnace causes these phases to either dissolve into the aluminum matrix, precipitate out, or aggregate.

Adjusting Baseline Hardness

By manipulating the strengthening phases, the furnace directly alters the material's hardness.

This allows manufacturers to reset the alloy's mechanical state. You can transition the sheet from a hard, brittle state to a softer state suitable for shaping, or vice versa.

Modifying Plasticity for Forming

Plasticity is essential for processes that deform the metal, such as SPIF.

The furnace treatments ensure the material has sufficient ductility to undergo deformation without cracking. This preparation is a prerequisite for achieving complex geometries during the forming stage.

Specific Treatment Cycles

Solution Heat Treatment

This process involves heating the alloy to high temperatures to dissolve soluble elements.

The primary reference highlights specific parameters, such as maintaining a temperature of 575°C. This ensures a uniform solid solution is created before subsequent steps.

Annealing (O Temper)

When maximum plasticity is required, the furnace is used for annealing.

This process softens the alloy, reducing internal stresses and maximizing ductility. It is the ideal preparation when the aluminum sheet must undergo significant mechanical deformation.

Artificial Aging (T6 Temper)

Once the material is formed, the furnace can be used to restore strength.

Through artificial aging, the furnace encourages the controlled precipitation of strengthening particles. This returns the component to a T6 temper, providing the rigidity and durability needed for the final product.

Critical Process Parameters

Precision Temperature Control

The effectiveness of the heat treatment hinges on thermal stability.

Industrial electric furnaces are utilized because they can maintain specific temperatures, such as the 575°C required for solution treatment, with high accuracy. Deviations here can result in inconsistent mechanical properties.

Managing Holding Times

Time is just as critical as temperature in these chemical reactions.

The reference notes specific durations, such as 2 hours, which allow sufficient time for the Mg2Si phases to reach the desired state. Cutting this time short prevents the complete dissolution or precipitation necessary for the target temper.

Understanding the Trade-offs

Plasticity vs. Strength

You cannot maximize both properties simultaneously in a single step.

The furnace allows you to prioritize plasticity (via annealing) to facilitate forming, but this temporarily sacrifices strength. Conversely, aging creates strength but reduces the material's ability to be formed without breaking.

The Cost of Precision

Achieving these specific tempers requires rigorous adherence to parameters.

If the furnace fails to hold 575°C consistently or if the 2-hour window is shortened, the material will not meet the baseline requirements for SPIF. There is no shortcut; the process requires exact compliance with the thermal recipe.

Making the Right Choice for Your Goal

To optimize your EN AW-6082 preparation, align the furnace cycle with your immediate manufacturing step:

- If your primary focus is complex shaping (SPIF): Utilize the furnace for Annealing (O Temper) to maximize plasticity and minimize the risk of cracking during deformation.

- If your primary focus is final structural integrity: Utilize the furnace for Solution Heat Treatment and Artificial Aging (T6) to precipitate Mg2Si and maximize hardness.

By leveraging the industrial electric furnace as a tool for phase management, you ensure your aluminum sheets are perfectly tuned to the demands of your specific fabrication process.

Summary Table:

| Heat Treatment Process | Target Temper | Primary Function | Key Parameters (Typical) |

|---|---|---|---|

| Annealing | O Temper | Maximizes plasticity & reduces stress for shaping | Softens material for deformation |

| Solution Heat Treatment | Pre-aging State | Dissolves Mg2Si phase into aluminum matrix | ~575°C for 2 hours |

| Artificial Aging | T6 Temper | Precipitates hardening phases for strength | Controlled cooling & reheating |

| Microstructure Control | N/A | Regulates hardness and ductility via Mg2Si | Precise thermal holding times |

Elevate Your Aluminum Processing Precision

Maximize the potential of EN AW-6082 and other advanced alloys with KINTEK’s high-performance industrial furnaces. Backed by expert R&D and world-class manufacturing, we provide Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for precise temperature control and uniform microstructure manipulation. Whether you need to optimize plasticity for SPIF or achieve maximum T6 hardness, our customizable lab and industrial solutions are engineered for your unique needs.

Ready to refine your heat treatment workflow? Contact KINTEK today for a consultation!

Visual Guide

References

- Łukasz Kuczek, Ryszard Sitek. Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. DOI: 10.3390/app15020783

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a forced air circulation oven required for Al-Cu-Mn alloy aging? Achieve Peak Hardness with Uniform Heat

- Why is the calcination step essential for Copper Ferrite? Unlock High Purity & Superior Crystallinity

- Why is a laboratory blast drying oven necessary for Ni-TiN catalysts? Ensure Precision in Precursor Treatment

- What is the importance of cold traps and pump recovery systems in VTD? Boost Safety and Material Recycling

- How does a stable constant temperature environment influence the structural development of LDHs during aging?

- What role does high-vacuum thermal evaporation equipment play in CsPbBr3 detectors? Optimize Electrode Fabrication

- How do water quenching and furnace cooling methods differ in their application to high-entropy alloys? Expert Insights

- What key data does a Simultaneous Thermal Analyzer (STA) provide for lignite combustion? Assess Fire Risk with Precision