The primary necessity of a laboratory blast drying oven in this process is to facilitate a controlled, slow dehydration of the impregnation slurry at a constant temperature. This specific equipment ensures the removal of physically adsorbed water without subjecting the mixture to rapid evaporation, which is critical for maintaining the structural integrity of the catalyst.

Core Takeaway The blast drying oven is not merely a heating device; it is a stabilization tool. Its function is to lock the Nickel (Ni) precursor in place on the Titanium Nitride (TiN) support by preventing the physical movement of fluids that occurs during rapid drying, ensuring the active metal remains uniformly dispersed.

The Physics of Controlled Drying

Regulating the Rate of Evaporation

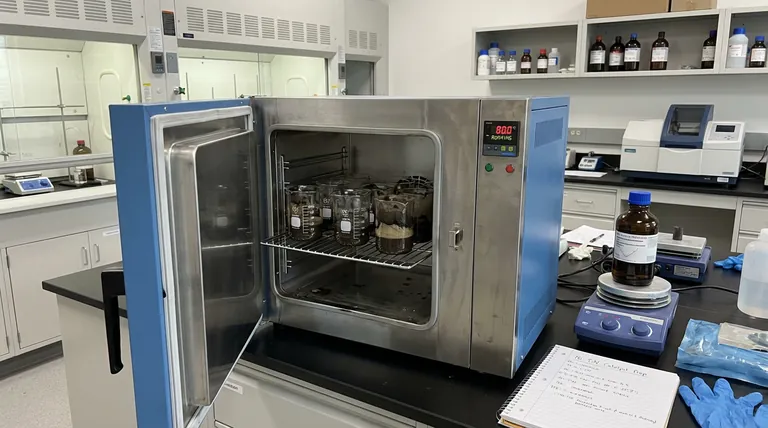

The blast drying oven utilizes hot air circulation to maintain a uniform temperature, often set to approximately 80 °C for Ni-TiN preparation.

Unlike static heating methods, the "blast" aspect ensures consistent airflow. This prevents hot spots and allows for a gradual, predictable evaporation rate across the entire sample batch.

Removal of Physically Adsorbed Water

The goal at this stage is to remove water that is physically clinging to the surface of the support.

By keeping the temperature moderate and constant over an extended period, the oven ensures that moisture is released systematically rather than explosively.

Preventing Solute Migration

The Danger of Violent Migration

When a solvent evaporates too quickly, it creates a capillary flow toward the surface of the porous support.

If this flow is "violent" or rapid, it drags the dissolved Nickel precursors along with it. This phenomenon results in the active metals pooling on the outer shell of the support rather than penetrating the pores.

Immobilizing the Precursor

The slow drying process provided by the oven effectively immobilizes the active metal salts.

By evaporating the solvent slowly, the viscosity of the solution increases gradually. This creates resistance to fluid movement, locking the precursor ions in their intended locations on the TiN support.

Protecting Component Distribution

Preserving the Initial State

The impregnation step establishes an ideal, initial distribution of the precursor on the TiN surface.

The blast drying oven protects this "initial distribution state." It ensures that the uniformity achieved during mixing is not undone during the drying phase.

Ensuring High Dispersion

Proper usage of the oven directly correlates to the final dispersion of the catalyst after calcination.

By preventing agglomeration (clumping) during drying, the oven ensures that the active Ni components remain finely divided and highly active in the final product.

Understanding the Trade-offs

The Risk of Rapid Heating

It is often tempting to increase the temperature to speed up the synthesis.

However, exceeding the optimal drying temperature (e.g., pushing well above 100°C too quickly) causes rapid vaporization. This leads to structural damage and uneven distribution, rendering the catalyst less effective.

Time vs. Homogeneity

The trade-off is time. A proper blast drying cycle is a lengthy process (often extending many hours).

Sacrificing this time for speed introduces non-uniform migration, where the active metal concentrates in specific areas, leading to poor catalytic performance.

Making the Right Choice for Your Goal

Achieving a high-performance Ni-TiN catalyst requires balancing efficiency with physical precision.

- If your primary focus is maximum dispersion: Prioritize a lower, constant temperature (e.g., 80 °C) with extended duration to minimize capillary flow.

- If your primary focus is structural integrity: Ensure the blast function is active to eliminate humidity gradients that could cause uneven stress on the support.

Ultimately, the blast drying oven acts as the safeguard that translates a well-mixed slurry into a chemically active, uniform solid catalyst.

Summary Table:

| Feature | Role in Ni-TiN Catalyst Preparation | Impact on Final Product |

|---|---|---|

| Hot Air Circulation | Ensures uniform temp (80°C) & prevents hot spots | Predictable, even evaporation |

| Controlled Dehydration | Removes physically adsorbed water slowly | Maintains structural integrity |

| Anti-Migration | Limits capillary flow of Nickel precursors | Prevents metal pooling & shell enrichment |

| Dispersion Control | Immobilizes active metal salts in pores | High catalytic activity & no agglomeration |

Elevate Your Catalyst Synthesis with KINTEK

Precision heating is the backbone of high-performance catalyst development. At KINTEK, we understand that maintaining structural integrity and uniform dispersion requires more than just heat—it requires control. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces, all customizable for your unique research needs.

Don't let rapid evaporation compromise your Ni-TiN catalyst performance. Contact us today to discover how our precision thermal solutions can optimize your precursor treatment and ensure maximum metal dispersion.

References

- Yi Zhu, Xunyu Lu. Making light work: designing plasmonic structures for the selective photothermal methanation of carbon dioxide. DOI: 10.1039/d3ey00315a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a planetary ball mill required for processing activated carbon? Achieve <30μm Particles for Superior Slurry

- Why is precise control of carrier gas flow rates required for hydrochar activation? Optimize Carbon Yield & Purity

- What is the technical necessity of sealing quartz ampoules at 10^-5 mbar for CVT? Ensure Crystal Purity

- What is shrinkage in the context of high-temperature materials? Master Dimensional Control for Stronger Parts

- Why is an automatically controlled mesh belt quenching line used for bearing rings? Precision & Stability Explained

- How does a magnetic stirring hot plate contribute to sol-gel synthesis? Expert Guide to Precursor Thin Film Success

- What is the importance of a stable thermal environment during crystallization? Ensure Precision in Metal Oxide Films

- How does a vacuum drying oven contribute to the study of the hydration degree in cement pastes? Essential Lab Insights