In high-temperature materials science, shrinkage is the reduction in a component's volume that occurs during manufacturing. This dimensional change is not caused by external pressure but is an inherent result of processes like drying, the intense heat of firing or sintering, and subsequent cooling.

The central challenge is not to eliminate shrinkage, but to predict and control it. For many advanced materials, shrinkage is the very mechanism that creates a strong, dense final part, making it a critical design parameter that must be precisely managed to ensure dimensional accuracy and prevent failure.

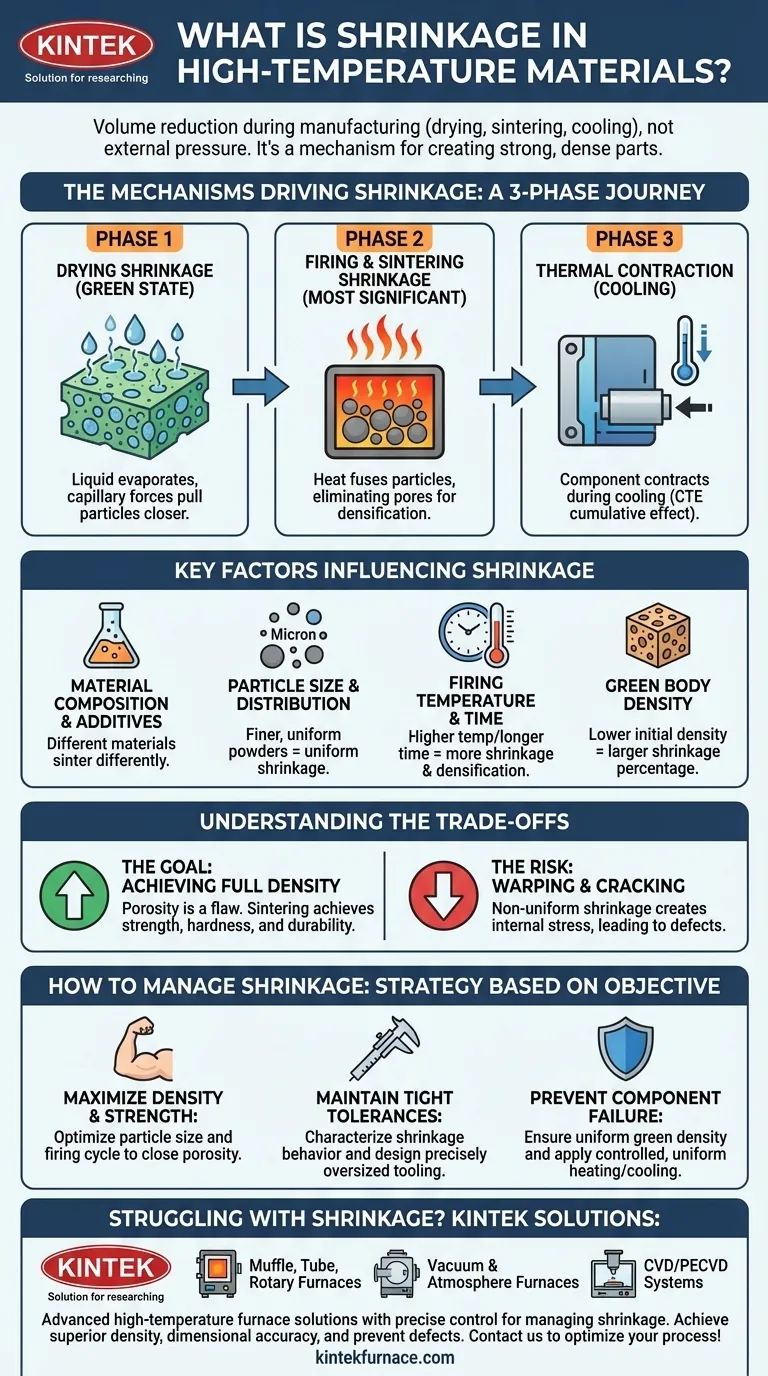

The Mechanisms Driving Shrinkage

Understanding why a material shrinks requires looking at three distinct, often sequential, phases of the manufacturing process. Each phase contributes to the total dimensional change.

Phase 1: Drying Shrinkage

Before high-temperature firing, a component is often in a "green" state, meaning it's a mix of the primary material powder and various binders or liquids. As this part dries, the liquid evaporates.

Capillary forces from the departing liquid pull the solid particles closer together, causing the part to shrink. This initial shrinkage is most significant in processes like ceramic slip casting or powder injection molding.

Phase 2: Firing & Sintering Shrinkage

This is the most significant phase for high-temperature materials like ceramics and powdered metals. Sintering is the process of fusing particles together using heat at temperatures below the material's melting point.

During sintering, atoms diffuse across the boundaries of particles, causing them to bond and grow together. This process eliminates the pores or empty spaces between the particles, which causes a dramatic and permanent reduction in the component's total volume. This is how a porous powder compact is transformed into a dense, strong solid.

Phase 3: Thermal Contraction (Cooling)

After reaching peak temperature during firing, the now-densified part must cool back to room temperature. Like most materials, it will contract as it cools.

This change is governed by the material's Coefficient of Thermal Expansion (CTE). While distinct from sintering shrinkage, it is a cumulative effect that must be factored into the final dimensions.

Key Factors Influencing Shrinkage

The exact amount of shrinkage is not a fixed number; it is highly sensitive to both the material itself and the process conditions.

Material Composition

Different materials inherently sinter and contract differently. Additives can be mixed into a powder to either promote or limit shrinkage and help control the final density.

Particle Size and Distribution

Finer and more uniformly sized powders generally pack more efficiently in the green state. This leads to more uniform and predictable shrinkage during firing, as there is less variation in the pores that need to be eliminated.

Firing Temperature and Time

Higher sintering temperatures and longer durations at that temperature increase the rate of atomic diffusion. This results in more complete pore elimination, leading to greater densification and, consequently, more shrinkage.

Green Body Density

The initial density of the unfired part is critical. A part with low green density has a high volume of pores. Eliminating this high porosity will result in a much larger percentage of shrinkage compared to a part that was already densely packed before firing.

Understanding the Trade-offs

Shrinkage is a double-edged sword; it is both a necessary tool for creating strong materials and a primary source of manufacturing defects.

The Goal: Achieving Full Density

For high-performance applications, porosity is a fatal flaw, as pores are stress concentrators where cracks can begin. Sintering shrinkage is the desired mechanism for achieving near-full density, which is directly correlated with a material's strength, hardness, and durability.

The Risk: Warping and Cracking

The danger lies in non-uniform shrinkage. If one part of a component heats faster or has a different green density, it will shrink at a different rate than its surroundings. This differential shrinkage creates immense internal stresses that can cause the part to warp, distort, or even crack during the process.

The Challenge: Predictability

The ultimate engineering challenge is to make shrinkage uniform and predictable. Manufacturers perform extensive testing to characterize a material's shrinkage rate. They then design their initial molds and tooling to be precisely oversized, anticipating the exact amount of shrinkage to achieve the final target dimensions.

How to Manage Shrinkage in Your Process

Controlling shrinkage is fundamental to success in high-temperature material processing. Your strategy will depend on your primary objective.

- If your primary focus is achieving maximum density and strength: You must embrace shrinkage as a tool, optimizing your material's particle size and the firing cycle to close as much porosity as possible.

- If your primary focus is maintaining tight dimensional tolerances: You must meticulously characterize your material's shrinkage behavior and design precisely oversized tooling to compensate for the expected volume loss.

- If your primary focus is preventing component failure: You must ensure uniform green body density and apply controlled, uniform heating and cooling profiles to prevent the differential shrinkage that leads to internal stress and cracking.

By treating shrinkage as a predictable engineering parameter rather than an unavoidable flaw, you gain control over the quality and performance of your final component.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | Volume reduction during manufacturing due to drying, sintering, and cooling, not external pressure. |

| Key Mechanisms | Drying shrinkage, firing/sintering shrinkage, thermal contraction. |

| Influencing Factors | Material composition, particle size, firing temperature/time, green body density. |

| Trade-offs | Achieves density and strength but risks warping/cracking if non-uniform. |

| Management Strategy | Predict and control shrinkage through material and process optimization for dimensional accuracy. |

Struggling with shrinkage in your high-temperature processes? KINTEK specializes in advanced high-temperature furnace solutions tailored for materials science labs. Our Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, combined with deep customization capabilities, ensure precise temperature control and uniform heating to manage shrinkage effectively. Achieve superior density, dimensional accuracy, and prevent defects in your components. Contact us today to discuss how we can optimize your manufacturing process!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating