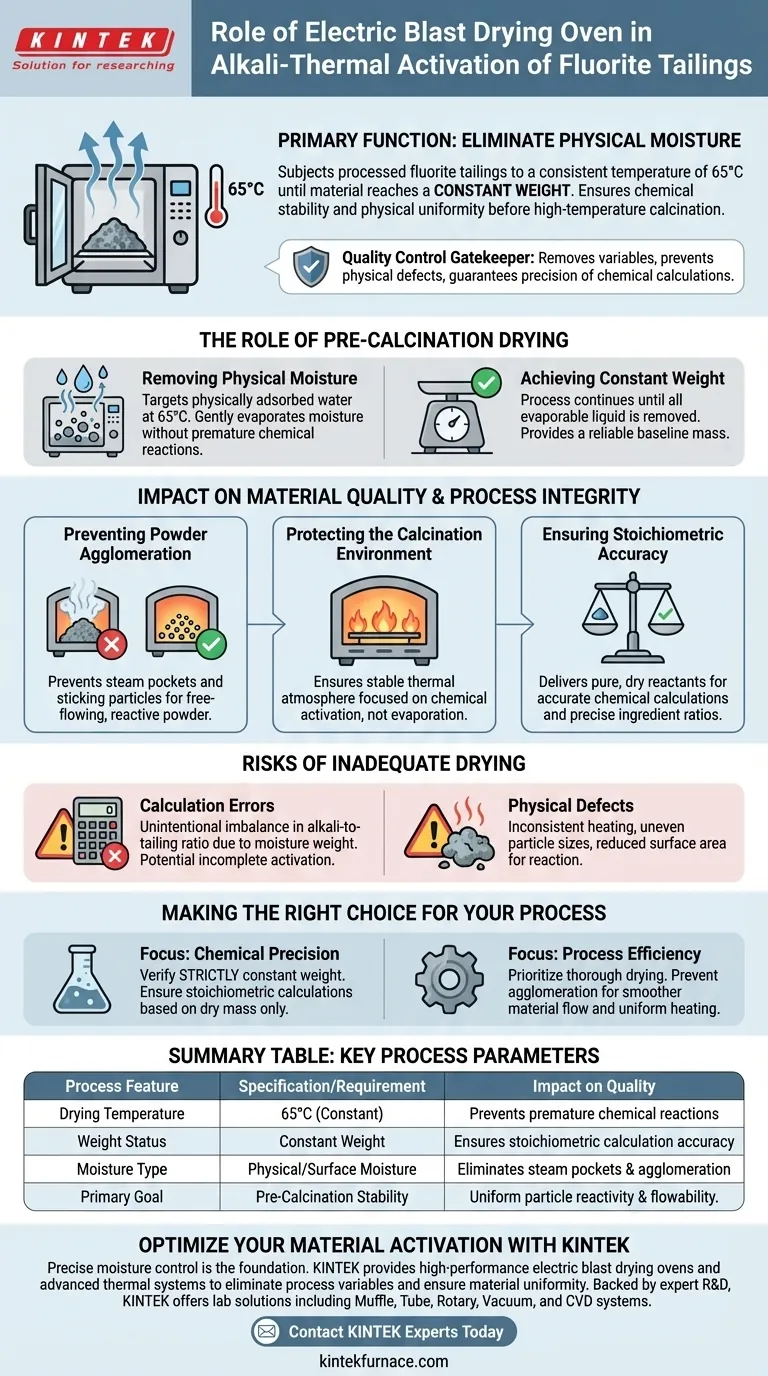

The primary function of an electric blast drying oven is to eliminate physical moisture. Specifically, it subjects processed fluorite tailings to a consistent temperature of 65°C until the material reaches a constant weight. This critical preparatory step ensures the raw material is chemically stable and physically uniform before it enters the high-temperature calcination phase.

The drying oven serves as a quality control gatekeeper, removing variables that could compromise the activation process. By ensuring tailings are dried to a constant weight, it prevents physical defects like clumping and guarantees the precision of chemical calculations required for successful alkali-thermal activation.

The Role of Pre-Calcination Drying

The drying process is not merely about removing water; it is about standardizing the material state. The electric blast drying oven prepares the tailings to behave predictably under intense heat.

Removing Physical Moisture

The oven targets water physically adsorbed onto the surface of the fluorite tailings. By maintaining a temperature of 65°C, the device gently evaporates this moisture without inducing premature chemical reactions.

Achieving Constant Weight

The process continues until the material reaches a constant weight. This indicates that all evaporable liquid has been removed, providing a reliable baseline mass for subsequent processing steps.

Impact on Material Quality and Process Integrity

The effectiveness of the subsequent calcination relies heavily on how well the drying oven performs its function.

Preventing Powder Agglomeration

If wet material enters a high-temperature calcination environment, rapid water evaporation can create steam pockets. This leads to powder agglomeration, where particles stick together. The drying oven prevents this, ensuring the powder remains free-flowing and reactive.

Protecting the Calcination Environment

Excess moisture can interfere with the thermal atmosphere inside a calcining kiln. By pre-drying the material, the oven ensures the calcination environment remains stable and focused on chemical activation rather than evaporation.

Ensuring Stoichiometric Accuracy

Chemical reactions depend on precise ratios of ingredients. If the tailings contain moisture, the weight measurement will include water mass, leading to incorrect calculations. The drying oven ensures accurate chemical stoichiometry by delivering pure, dry reactants.

Risks of Inadequate Drying

Skipping or rushing this stage introduces significant variables that can degrade the final product.

Calculation Errors

If the material is not dried to a constant weight, operators will unintentionally add less fluorite tailing than required. This imbalance disrupts the alkali-to-tailing ratio, potentially leading to incomplete activation.

Physical Defects

Residual moisture causes inconsistent heating. This often results in uneven particle sizes or clumping, which reduces the surface area available for the alkali-thermal reaction.

Making the Right Choice for Your Process

To maximize the efficiency of alkali-thermal activation, consider these specific operational goals when utilizing the drying oven.

- If your primary focus is Chemical Precision: Verify that the material has reached a strictly constant weight to ensure your stoichiometric calculations are based on dry mass only.

- If your primary focus is Process Efficiency: Prioritize thorough drying to prevent agglomeration, which facilitates smoother material flow and more uniform heating during calcination.

A properly executed drying phase is the foundation for a predictable and high-yield activation process.

Summary Table:

| Process Feature | Specification/Requirement | Impact on Quality |

|---|---|---|

| Drying Temperature | 65°C (Constant) | Prevents premature chemical reactions |

| Weight Status | Constant Weight | Ensures stoichiometric calculation accuracy |

| Moisture Type | Physical/Surface Moisture | Eliminates steam pockets & agglomeration |

| Primary Goal | Pre-Calcination Stability | Uniform particle reactivity & flowability |

Optimize Your Material Activation with KINTEK

Precise moisture control is the foundation of successful alkali-thermal activation. KINTEK provides high-performance electric blast drying ovens and advanced thermal systems designed to eliminate process variables and ensure material uniformity.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are processing fluorite tailings or advanced ceramics, our equipment is fully customizable to meet your unique thermal processing needs.

Ready to enhance your lab's efficiency and chemical precision?

Visual Guide

References

- Hao Qiu, Xiao Wang. Preparation and mechanical performance of fluorite tailings geopolymer precursor under alkaline heat activation. DOI: 10.1038/s41598-024-82560-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does the sintering process enhance conventional ceramics with Alumina? Boost Strength and Insulation

- Why is the precision of an automatic temperature-controlled furnace critical in glass synthesis? Achieve 1350°C Accuracy

- Why is a nitrogen flow control system essential for biochar? Achieve Precise Pyrolysis & High-Quality Carbon Yields

- What is the function of the heating device in the micro-Kjeldahl method? Master Protein Analysis in Mushrooms

- How do heat exchangers contribute to energy efficiency? Boost Your Hybrid Power System Performance

- How does a laboratory furnace operate? Master Heating Principles for Your Lab

- What are the advantages of a benchtop industrial oven in terms of usability? Enhance Lab Efficiency with Compact Design

- Why is titanium used as a gettering agent in TiCo1-xCrxSb preparation? Achieve Purity in Your Alloy Synthesis