At its core, a laboratory furnace operates by converting electrical energy into thermal energy and transferring that heat to a sample within an insulated chamber. This process relies on a specific heating mechanism, such as electrical resistance or electromagnetic induction, to generate high temperatures. The heat is then delivered to the sample through a combination of convection, conduction, and radiation.

While all laboratory furnaces heat samples, the specific method they use—from resistive coils to electromagnetic fields—is fundamentally tied to the material being heated and the desired outcome. Understanding this distinction is the key to selecting the right tool for your research.

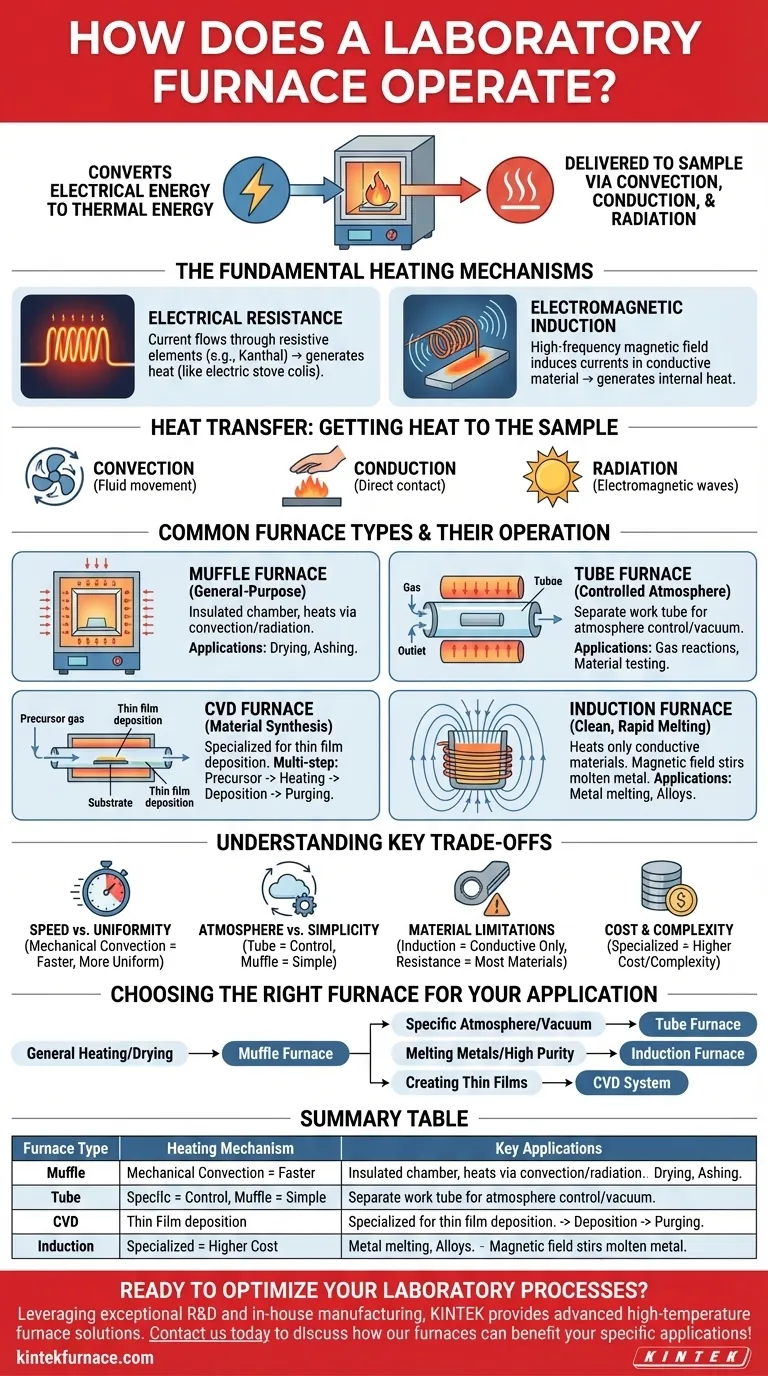

The Fundamental Heating Mechanisms

To understand how a furnace works, you must first understand how it generates and transfers heat. These two core principles define the furnace's capabilities and limitations.

Electrical Resistance: The Workhorse Principle

The vast majority of laboratory furnaces, including muffle and tube furnaces, operate using electrical resistance.

Current is passed through specialized heating elements, often made of materials like Kanthal or silicon carbide. These materials resist the flow of electricity, causing them to get extremely hot, much like the coils in an electric stove.

Electromagnetic Induction: For Conductive Materials

An induction furnace uses a completely different principle. It generates a powerful, high-frequency magnetic field using a water-cooled copper coil.

When a conductive material, such as metal, is placed within this field, the magnetic field induces electrical currents (eddy currents) within the metal itself. The metal's own internal resistance to these currents generates rapid and precise heat.

Heat Transfer: Getting Heat to the Sample

Once heat is generated, it must reach the sample.

- Convection: Heat is transferred through the movement of a fluid, typically air or a specific gas. Gravity convection relies on the natural principle of hot air rising, while mechanical convection uses fans and blowers for faster, more uniform temperature distribution.

- Conduction: Heat is transferred through direct physical contact. The furnace walls and sample holder conduct heat directly to the sample.

- Radiation: At high temperatures, heat is transferred via electromagnetic waves (infrared radiation), which travel from the hot elements directly to the sample without needing a medium.

Common Furnace Types and Their Operation

The fundamental principles of heating are applied in different ways across various furnace designs, each optimized for a specific task.

The Muffle Furnace: General-Purpose Heating

A muffle furnace is a box-style furnace where heating elements line the walls of an insulated chamber. The term "muffle" historically referred to the inner ceramic chamber that protected the sample from the fuel and combustion byproducts in older furnace designs.

In modern electric furnaces, it simply refers to the insulated chamber that contains the sample, heating it primarily through convection and radiation.

The Tube Furnace: For Controlled Atmospheres

A tube furnace heats samples inside a separate, cylindrical work tube, typically made of quartz, alumina, or mullite. The heating elements are positioned outside this tube.

This design is critical for processes that require a controlled atmosphere. Samples are loaded into the tube, which can then be sealed and purged with an inert gas, a reactive gas, or evacuated to create a vacuum. The furnace heats the tube, and the tube in turn heats the sample.

The CVD Furnace: A System for Material Synthesis

A Chemical Vapor Deposition (CVD) furnace is a highly specialized type of tube furnace designed for a single purpose: creating thin solid films on a substrate.

Its operation is a multi-step process:

- Precursor Introduction: Gaseous chemicals (precursors) are precisely introduced into the tube.

- Heating: The furnace heats the chamber to a temperature that triggers a chemical reaction.

- Deposition: The precursors react and "deposit" a solid thin film onto the surface of a substrate inside the tube.

- Cooling & Purging: The system is cooled, and unreacted gases are purged from the chamber.

The Induction Furnace: For Clean, Rapid Melting

An induction furnace is designed for melting metals and creating alloys. It consists of the copper coil surrounding a non-conductive container, or crucible, which holds the metal.

Because it only heats the conductive material, the crucible walls remain much cooler. This results in a very clean melt with minimal contamination. A unique benefit is that the magnetic field also stirs the molten metal, ensuring excellent mixing and alloy homogeneity.

Understanding the Key Trade-offs

No single furnace design is perfect for all applications. The choice of furnace involves balancing several critical factors.

Speed vs. Uniformity

A furnace with mechanical convection (using a fan) will achieve a target temperature faster and provide much greater temperature uniformity throughout the chamber than one relying on gravity convection.

Atmosphere Control vs. Simplicity

A standard muffle furnace is simple to operate for heating in air. A tube furnace offers precise atmosphere control but adds the complexity of gas lines, vacuum pumps, and sealing flanges.

Material Limitations

The most significant limitation is with induction furnaces, which can only heat electrically conductive materials. Resistance furnaces, by contrast, can heat nearly any material placed inside them.

Cost and Complexity

As a general rule, complexity and cost increase with specialization. A simple gravity convection muffle furnace is the most economical, while specialized systems like CVD and induction furnaces represent a significantly higher investment.

Choosing the Right Furnace for Your Application

Your final choice depends entirely on your specific research goal.

- If your primary focus is general-purpose heating, drying, or ashing of non-reactive samples: A standard muffle furnace with gravity or mechanical convection is your most reliable and cost-effective choice.

- If your primary focus is heating samples in a specific gas atmosphere (inert or reactive) or vacuum: A tube furnace is essential for the isolation and process control it provides.

- If your primary focus is melting metals or synthesizing alloys with high purity and homogeneity: An induction furnace offers unmatched speed, cleanliness, and a unique stirring capability.

- If your primary focus is creating high-purity thin films on a substrate: A dedicated Chemical Vapor Deposition (CVD) system is required for its precise control over precursor gases and reaction conditions.

By matching the furnace's operating principle to your specific material and process goals, you ensure accurate, repeatable, and successful results.

Summary Table:

| Furnace Type | Heating Mechanism | Key Applications |

|---|---|---|

| Muffle Furnace | Electrical Resistance | General heating, drying, ashing |

| Tube Furnace | Electrical Resistance | Controlled atmosphere, gas reactions |

| CVD Furnace | Electrical Resistance | Thin film deposition, material synthesis |

| Induction Furnace | Electromagnetic Induction | Metal melting, alloy creation |

Ready to optimize your laboratory processes? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need precise temperature control, atmosphere management, or specialized synthesis, we have the expertise to enhance your efficiency and results. Contact us today to discuss how our furnaces can benefit your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals