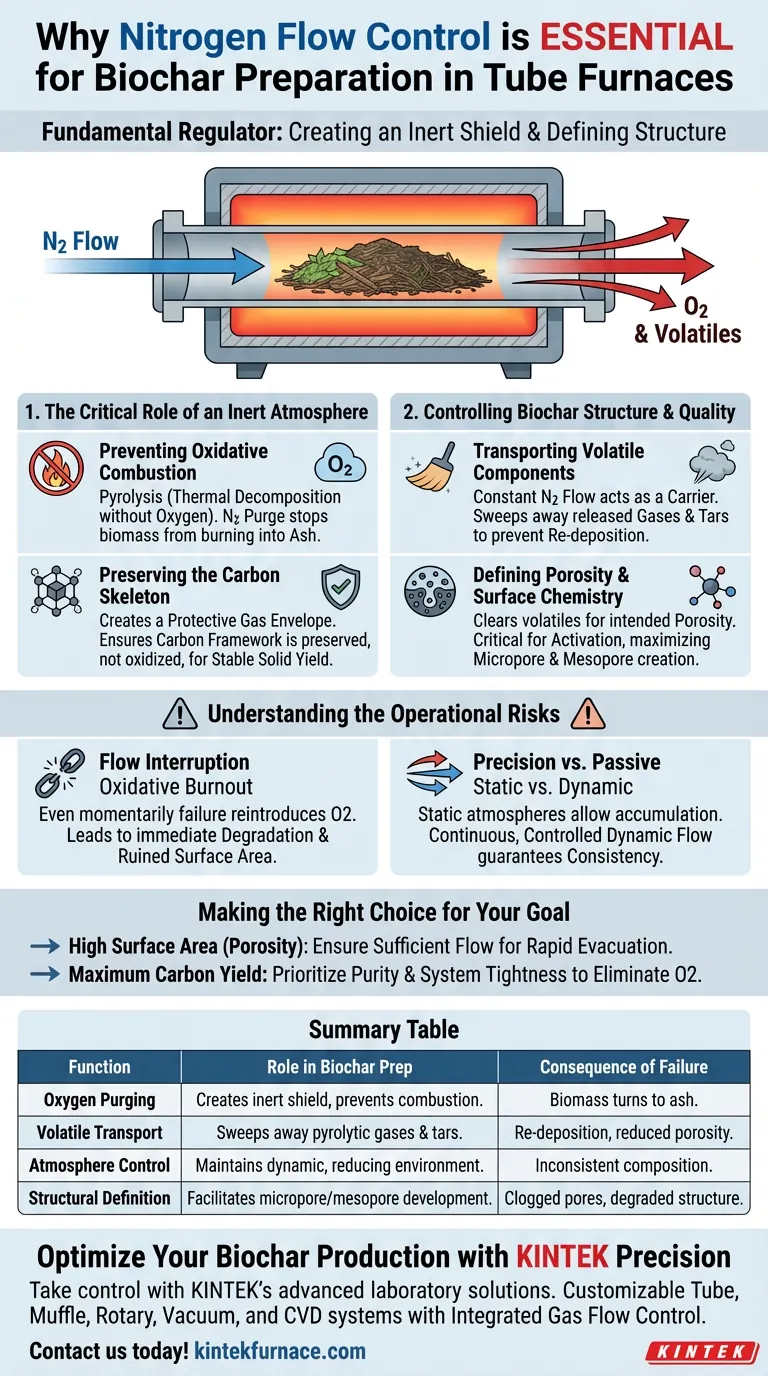

A nitrogen flow control system acts as the fundamental regulator of the chemical environment during biochar preparation. It is essential because it continuously purges oxygen from the tube furnace to prevent the biomass from burning into ash, while simultaneously transporting volatile byproducts away from the sample to define its physical structure.

The system serves two non-negotiable functions: creating an inert "shield" to prevent combustion and providing a dynamic transport mechanism to remove pyrolytic gases, thereby strictly controlling the biochar’s porosity and surface chemistry.

The Critical Role of an Inert Atmosphere

Preventing Oxidative Combustion

Biochar production relies on pyrolysis, which is thermal decomposition in the absence of oxygen.

Without a continuous nitrogen purge, the high temperatures inside the furnace (typically 400–700 °C) would cause the biomass to react with oxygen.

This results in complete combustion, leaving behind useless ash instead of carbon-rich char.

Preserving the Carbon Skeleton

The nitrogen flow creates a protective gas envelope around the sample.

This "reducing environment" ensures that the carbon framework of the wood or biomass is preserved rather than oxidized.

By effectively excluding oxygen, the system allows for the precise carbonization necessary to achieve a stable solid yield.

Controlling Biochar Structure and Quality

Transporting Volatile Components

As biomass heats up, it releases various volatile gases and tars.

A constant nitrogen flow rate acts as a carrier vehicle, sweeping these volatiles away from the solid sample.

This prevents these byproducts from lingering and potentially reacting with or re-depositing on the biochar surface.

Defining Porosity and Surface Chemistry

The removal of volatiles is not just a cleanup step; it is a structural requirement.

By clearing these gases, the system ensures the development of the intended porosity and surface functional groups.

This is particularly critical during activation processes, where the gas flow allows activating agents to etch the carbon framework efficiently, maximizing micropore and mesopore creation.

Understanding the Operational Risks

The Consequence of Flow Interruption

The reliability of the nitrogen supply is as critical as the furnace temperature.

Even a momentary failure in the flow control system can reintroduce oxygen into the chamber.

At high temperatures, this leads to immediate oxidative burnout, degrading the graphitic structure and ruining the sample's surface area properties.

Precision vs. Passive Displacement

Simply filling the chamber with nitrogen is insufficient; the flow must be continuous and controlled.

Static atmospheres allow volatiles to accumulate, altering the chemical composition of the final product.

Therefore, the dynamic nature of the flow is what guarantees consistency in carbon content and pore development batch after batch.

Making the Right Choice for Your Goal

To maximize the quality of your biochar, you must tune your nitrogen system based on your specific objectives.

- If your primary focus is High Surface Area (Porosity): Ensure the flow rate is sufficient to rapidly evacuate volatiles, allowing micropores to develop without clogging.

- If your primary focus is Maximum Carbon Yield: Prioritize the purity of the nitrogen source and system tightness to strictly eliminate any trace of oxygen that causes burnout.

Control the flow, and you control the chemistry of your final product.

Summary Table:

| Function | Role in Biochar Preparation | Consequence of Failure |

|---|---|---|

| Oxygen Purging | Creates an inert shield to prevent oxidative combustion. | Biomass turns to ash instead of stable carbon char. |

| Volatile Transport | Sweeps away pyrolytic gases and tars from the sample surface. | Re-deposition of tars and reduced porosity/surface area. |

| Atmosphere Control | Maintains a dynamic, reducing environment for carbonization. | Inconsistent chemical composition and surface chemistry. |

| Structural Definition | Facilitates the development of micropores and mesopores. | Clogged pores and degraded graphitic structure. |

Optimize Your Biochar Production with KINTEK Precision

Take full control of your pyrolysis environment with KINTEK’s advanced laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable with integrated gas flow control to ensure your biochar achieves maximum porosity and carbon stability.

Don't let oxygen contamination or inconsistent flow ruin your research. Contact us today to find the perfect customizable high-temp furnace for your unique needs!

Visual Guide

References

- Shrikanta Sutradhar, Kang Kang. Comparison of Oil-Seed Shell Biomass-Based Biochar for the Removal of Anionic Dyes—Characterization and Adsorption Efficiency Studies. DOI: 10.3390/plants13060820

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of FE-SEM for SSBSN ceramics? Master Morphological Analysis for Superior Electrical Performance

- How do laboratory thermostatic baths contribute to the phosphoric acid treatment of 3Y-TZP ceramics? Boost Bioactivity

- What are the advantages of using KOH as a chemical activator? Enhance Biomass Carbon Surface Area and Porosity

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces

- Why is industrial-grade isostatic pressing necessary for zirconia? Achieve Uniform Density & Structural Integrity

- Why is a sealed heating vessel used with a stepped heating process to infiltrate sulfur? Maximize Li-S Battery Performance

- Why is charcoal used as a susceptor in MHH for metal powders? Boost Microwave Efficiency with Hybrid Heating

- Why must high-purity argon gas be introduced for aluminum matrix composites? Ensure Sintering Success with KINTEK