High-temperature furnace systems provide critical precision for modifying material properties necessary for flexible electronics. Specifically, configurations like tube and Chemical Vapor Deposition (CVD) furnaces allow engineers to decouple mechanical flexibility from electrical conductivity through strictly controlled thermal treatments.

By enabling specific high-heat processes in regulated gas environments, these systems allow for the synthesis of composite materials that maintain electrical integrity even under significant stretching and cyclic loading.

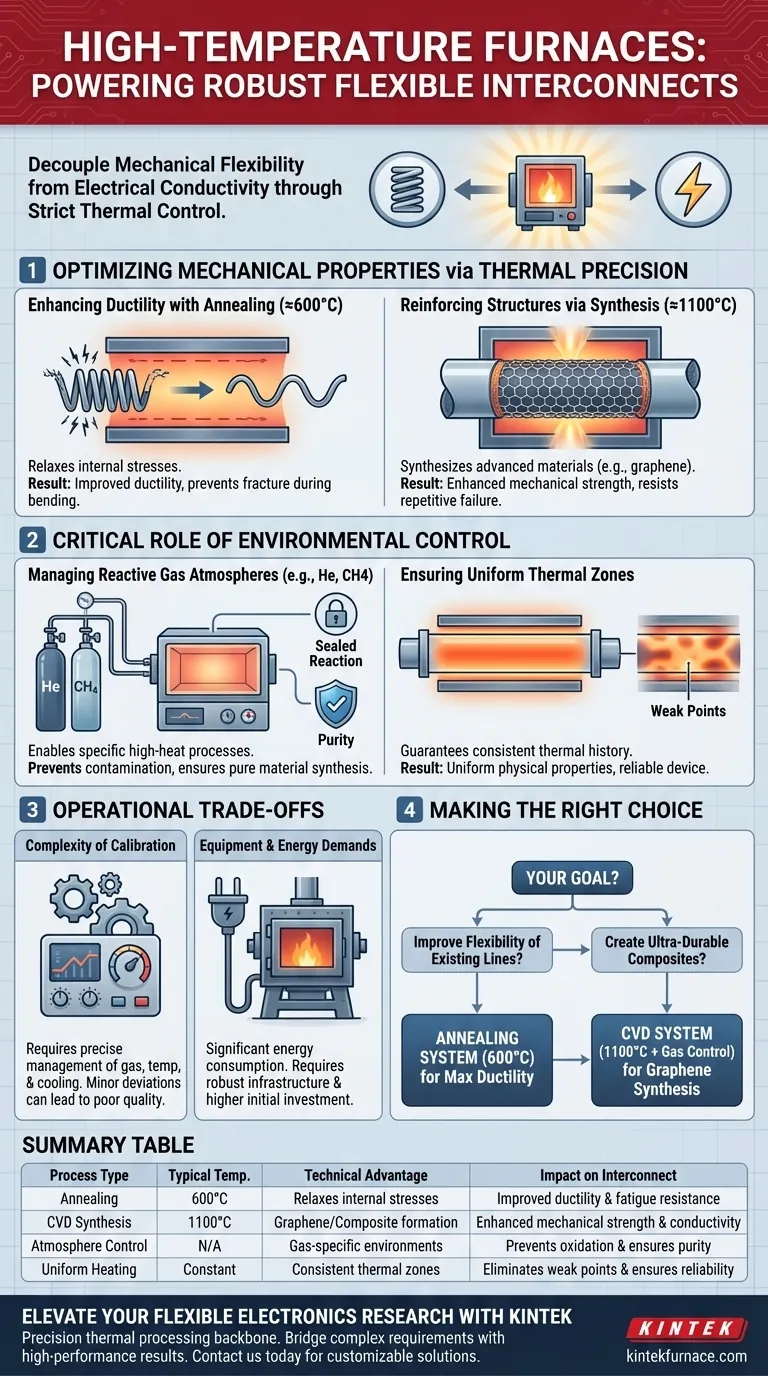

Optimizing Mechanical Properties Through Thermal Precision

Enhancing Ductility with Annealing

The primary challenge in flexible interconnects is preventing metal fatigue during movement. High-temperature furnaces solve this by enabling precise annealing processes at approximately 600°C.

This thermal treatment relaxes the internal stresses of conductive metals. The result is significantly improved ductility, allowing the interconnect to bend and twist without fracturing.

Reinforcing Structures via Synthesis

Beyond simple annealing, these systems support high-temperature synthesis at much higher thresholds, such as 1100°C. This capability is essential for creating advanced reinforcing materials like graphene.

By synthesizing graphene layers directly onto or within the interconnect structure, engineers can enhance the material's mechanical strength. This creates a robust composite that resists failure during repetitive use.

The Critical Role of Environmental Control

Managing Reactive Gas Atmospheres

Temperature is only half the equation; the chemical environment is equally critical. High-temperature systems are designed to handle specific gas flows, such as helium or methane, safely and effectively.

These gases are often required precursors or carrier gases for synthesizing advanced materials like graphene. The furnace acts as a sealed reaction chamber, preventing contamination and ensuring pure material synthesis.

Ensuring Uniform Thermal Zones

Inconsistent heating leads to weak points in an interconnect, which become failure points under stress. High-quality furnace systems utilize expert R&D and advanced manufacturing to guarantee uniform temperature zones.

This uniformity ensures that the entire length of the interconnect undergoes the exact same thermal history. Consequently, the physical properties—such as elasticity and conductivity—remain consistent throughout the device.

Understanding the Operational Trade-offs

Complexity of Calibration

Achieving these results requires rigorous calibration. The "strict control" mentioned requires precise management of gas flow rates, temperature ramp speeds, and cooling cycles. A minor deviation in the gas mixture or temperature profile can lead to poor graphene quality or oxidized metals.

Equipment and Energy Demands

Operating at 1100°C implies significant energy consumption and requires robust laboratory infrastructure. As noted in manufacturing standards, these systems must be built to exacting specifications to handle such extremes safely, representing a higher initial investment than standard drying ovens.

Making the Right Choice for Your Goal

To select the correct furnace configuration for your flexible interconnect project, consider your specific material requirements:

- If your primary focus is improving the flexibility of existing metal lines: Prioritize systems capable of stable, uniform annealing at 600°C to maximize ductility.

- If your primary focus is creating ultra-durable, next-generation composites: You require a CVD-capable system that can safely reach 1100°C and manage hydrocarbon gases for graphene synthesis.

Success in flexible electronics relies not just on the materials you choose, but on the precision of the thermal history you subject them to.

Summary Table:

| Process Type | Typical Temp. | Technical Advantage | Impact on Interconnect |

|---|---|---|---|

| Annealing | 600°C | Relaxes internal stresses | Improved ductility & fatigue resistance |

| CVD Synthesis | 1100°C | Graphene/Composite formation | Enhanced mechanical strength & conductivity |

| Atmosphere Control | N/A | Gas-specific environments | Prevents oxidation & ensures material purity |

| Uniform Heating | Constant | Consistent thermal zones | Eliminates weak points & ensures device reliability |

Elevate Your Flexible Electronics Research with KINTEK

Precision thermal processing is the backbone of next-generation interconnect technology. At KINTEK, we bridge the gap between complex material requirements and high-performance results. Backed by expert R&D and world-class manufacturing, we provide a comprehensive suite of Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your laboratory's specific needs.

Whether you are focusing on high-ductility annealing or complex graphene synthesis, our systems offer the customizable controls and uniform thermal zones essential for your success. Contact us today to find the perfect customizable high-temp solution for your research.

Visual Guide

References

- Kaihao Zhang, Sameh Tawfick. Ultrathin damage-tolerant flexible metal interconnects reinforced by in-situ graphene synthesis. DOI: 10.1038/s41528-024-00300-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is precise temperature control programming indispensable for SFC research? Optimize Sintering Process Success

- What is the purpose of high-purity argon in Fe60Co10-xNi15Cr15Six alloy preparation? Ensure Purity for Laser Cladding

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation

- What role does a nitrogen protection device play in copper-based halide thin films? Optimize Your Lab Annealing Process

- How does a high-temperature laboratory furnace contribute to the formation of high-quality CsV3Sb5 single crystals?

- What is the chemical vapor transport technique? A Guide to High-Purity Crystal Growth

- Why is high-temperature stability important for Cu2O substrates? Ensure Long-Term Electrocatalytic Efficiency