In short, Chemical Vapor Transport (CVT) is a method for growing high-purity crystals or purifying solid materials. It works by using a chemical "transport agent" to convert a solid material into a gaseous compound at one temperature, which then moves and decomposes back into a purified solid at a different temperature. This entire process is controlled within a tube furnace, which provides the precise temperature zones required.

The core principle of Chemical Vapor Transport is leveraging a reversible chemical reaction driven by a temperature difference. A tube furnace is the ideal instrument for this task because it creates the stable, controlled hot and cold zones necessary to drive the reaction forward and in reverse, enabling the transport and purification of materials.

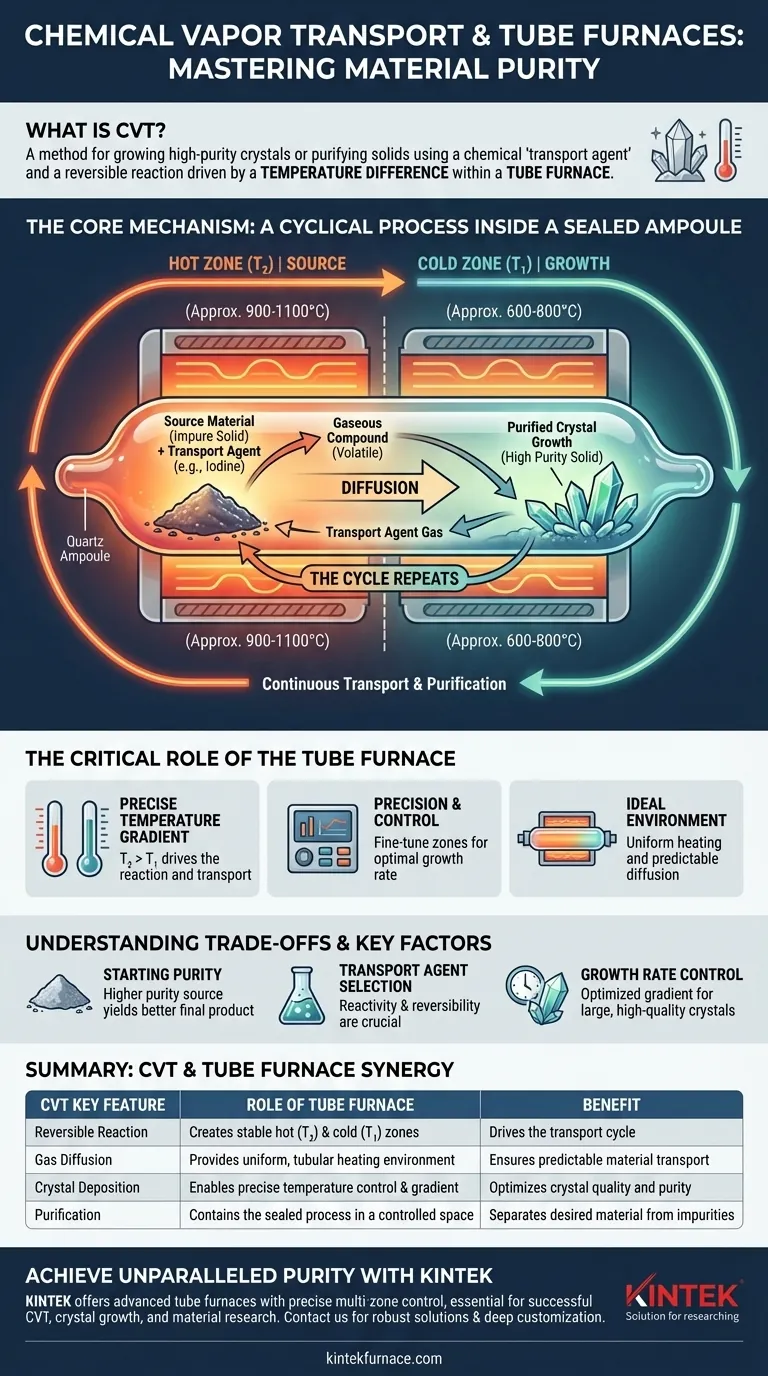

How Chemical Vapor Transport Works: The Core Mechanism

Chemical Vapor Transport can be visualized as a cyclical, self-contained purification process. It takes place inside a sealed tube, typically made of quartz, called an ampoule.

The Key Ingredients

First, the starting material (the substance to be purified or grown, like tantalum powder) and a small amount of a transport agent (often a halogen like iodine) are placed inside the ampoule. The ampoule is then evacuated to a high vacuum and sealed shut.

Step 1: Reaction in the Hot Zone (T₂)

The sealed ampoule is placed inside a two-zone tube furnace. One end, the "source zone," is heated to a higher temperature (T₂). Here, the source material reacts with the gaseous transport agent to form a new, volatile gaseous compound.

Step 2: Diffusion to the Cold Zone (T₁)

This newly formed gas mixture slowly diffuses from the hot zone towards the other end of the ampoule, which is held at a slightly lower temperature (T₁), the "growth zone."

Step 3: Deposition and Crystal Growth

In this cooler zone, the chemical equilibrium shifts. The reaction reverses, causing the gaseous compound to decompose. It deposits the original material—now in a highly pure, crystalline form—onto the wall of the ampoule and releases the transport agent.

Step 4: The Cycle Repeats

The freed transport agent gas is now ready to diffuse back towards the hotter source zone (T₂) to react with more of the starting material, repeating the cycle continuously. Over time, this process transports the material from the hot end to the cold end, leaving impurities behind and forming high-quality crystals.

The Critical Role of the Tube Furnace

The tube furnace is not just an oven; it is the engine that drives the entire CVT process. Its specific design is what makes this technique so effective and repeatable.

Establishing the Temperature Gradient

The most crucial function of the furnace is to create and maintain a precise temperature gradient (T₂ > T₁) along the length of the sealed ampoule. This temperature difference is the sole driving force for the chemical transport.

Precision and Control

Modern tube furnaces, especially multi-zone models, offer exceptional temperature stability and control. Researchers can fine-tune the temperatures of the hot and cold zones to optimize the transport rate and the quality of the resulting crystals.

The Ideal Environment

The tubular shape is perfect for holding the sealed ampoule, ensuring uniform heating around its circumference. This geometry promotes a predictable and stable diffusion of gases from one end to the other.

Understanding the Trade-offs

While powerful, CVT is a technique that requires careful planning and control to achieve the desired results.

Purity of Starting Materials

The process purifies materials, but starting with higher-purity source materials will yield a better final product and a more efficient process. Certain impurities can interfere with the transport reaction.

Choosing the Transport Agent

The selection of the transport agent is critical. It must react with the source material reversibly within a practical temperature range and must not permanently incorporate itself into the final crystal lattice.

Controlling the Growth Rate

The rate of crystal growth is determined by the temperature difference between the two zones. A very large difference can lead to rapid transport but may result in many small, poorly formed crystals. A smaller, optimized gradient promotes slower growth, which is essential for forming large, high-quality single crystals.

When to Consider Chemical Vapor Transport

The decision to use CVT is based on the specific material and the desired outcome. It is a specialized technique for applications where purity and crystalline structure are paramount.

- If your primary focus is creating high-purity single crystals: CVT is one of the premier methods for growing crystals of materials like transition metal dichalcogenides (e.g., TaS₂), which are vital in electronics and research.

- If your primary focus is purifying a non-volatile solid: This technique can effectively separate a desired element or compound from less reactive or non-volatile impurities left behind in the hot zone.

- If your primary focus is exploring novel materials: CVT allows for synthesis and crystal growth under very clean, controlled conditions, enabling the creation of materials that are difficult to produce by other means.

Ultimately, chemical vapor transport is a powerful demonstration of how controlling thermal energy with a tool like a tube furnace can be used to drive chemical reactions and create materials with exceptional purity.

Summary Table:

| CVT Key Feature | Role of Tube Furnace | Benefit |

|---|---|---|

| Reversible Reaction | Creates stable hot (T₂) & cold (T₁) zones | Drives the transport cycle |

| Gas Diffusion | Provides uniform, tubular heating environment | Ensures predictable material transport |

| Crystal Deposition | Enables precise temperature control & gradient | Optimizes crystal quality and purity |

| Purification | Contains the sealed process in a controlled space | Separates desired material from impurities |

Ready to achieve unparalleled purity in your materials research?

Chemical Vapor Transport demands precise thermal control, and KINTEK's advanced tube furnaces are engineered to deliver it. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions featuring multi-zone temperature control and uniform heating profiles—essential for successful CVT.

Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements, whether you are growing single crystals or purifying novel materials.

Contact KINTEK today to discuss how our high-temperature furnace solutions can power your next breakthrough.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability