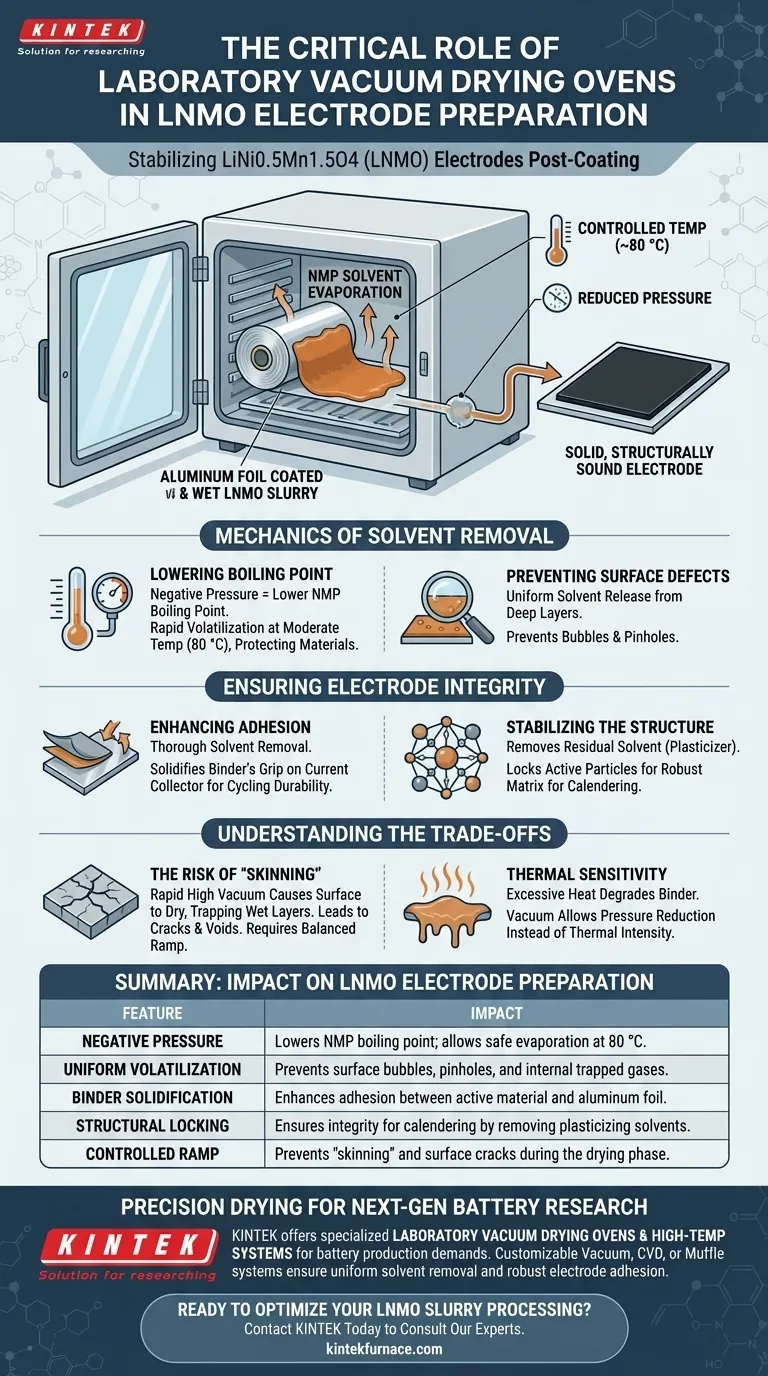

The laboratory vacuum drying oven plays a decisive role in stabilizing LiNi0.5Mn1.5O4 (LNMO) electrodes immediately after the coating process. By applying a controlled temperature (typically 80 °C) within a reduced pressure environment, it ensures the rapid and complete evaporation of the N-methyl-2-pyrrolidone (NMP) solvent from the slurry coated on the aluminum foil. This step is fundamental to transforming the wet slurry into a solid, structurally sound electrode.

The vacuum drying process is not merely about evaporation; it is a critical quality control mechanism that prevents coating defects and ensures robust adhesion between the active material and the current collector.

The Mechanics of Solvent Removal

Lowering the Boiling Point

The NMP solvent used in LNMO slurries has a high boiling point, making it difficult to remove via heat alone without damaging the components.

The vacuum oven utilizes negative pressure to significantly lower this boiling point. This allows the solvent to volatilize rapidly at a moderate temperature (e.g., 80 °C), protecting the thermal stability of the electrode materials.

Preventing Surface Defects

Drying a thick slurry coating can often lead to trapped gases or uneven evaporation.

The vacuum environment facilitates a uniform release of solvent from the deep layers of the coating. This prevents the formation of bubbles or pinholes on the coating surface, which are common causes of electrode failure.

Ensuring Electrode Integrity

Enhancing Adhesion

The mechanical strength of a battery electrode relies on how well the active material sticks to the aluminum foil current collector.

By thoroughly removing the NMP solvent, the vacuum drying process solidifies the binder's grip on the foil. This enhanced adhesion is vital for maintaining electrical contact during the expansion and contraction of battery cycling.

Stabilizing the Structure

Residual solvent acts as a plasticizer, making the electrode coating soft and unstable.

Complete drying ensures the "structural integrity" of the LNMO electrode. It locks the active particles in place, creating a robust matrix that can withstand subsequent manufacturing steps like calendering (pressing).

Understanding the Trade-offs

The Risk of "Skinning"

While vacuum drying is efficient, applying high vacuum too quickly can cause the surface to dry while the bottom layers remain wet.

This phenomenon, known as "skinning," can lead to surface cracks or internal voids. The process requires a balance of temperature and pressure to ensure the solvent evaporates evenly throughout the thickness of the coating.

Thermal Sensitivity

Although 80 °C is standard for LNMO, excessive heat in an attempt to speed up drying can degrade the polymeric binder.

If the binder degrades, the electrode will lose flexibility and adhesion. The vacuum oven allows you to avoid these high-temperature risks by relying on pressure reduction rather than thermal intensity.

Making the Right Choice for Your Goal

To optimize the preparation of your LNMO electrodes, align your drying protocol with your specific quality metrics.

- If your primary focus is Physical Durability: Prioritize a gradual ramp in vacuum pressure to prevent surface cracking and ensure the binder distributes uniformly.

- If your primary focus is Electrochemical Performance: Ensure the drying duration is sufficient to remove all traces of NMP, as residual solvent will impede electron transfer and weaken adhesion.

The success of your LNMO battery cell is often determined not by the chemistry alone, but by the precision of the drying phase that solidifies it.

Summary Table:

| Feature | Impact on LNMO Electrode Preparation |

|---|---|

| Negative Pressure | Lowers NMP boiling point; allows safe evaporation at 80 °C. |

| Uniform Volatilization | Prevents surface bubbles, pinholes, and internal trapped gases. |

| Binder Solidification | Enhances adhesion between active material and aluminum foil. |

| Structural Locking | Ensures integrity for calendering by removing plasticizing solvents. |

| Controlled Ramp | Prevents "skinning" and surface cracks during the drying phase. |

Precision Drying for Next-Generation Battery Research

Achieving the perfect LNMO electrode requires more than just chemistry; it requires a controlled thermal environment that preserves material integrity. Backed by expert R&D and manufacturing, KINTEK offers specialized Laboratory Vacuum Drying Ovens and high-temp systems designed for the rigorous demands of battery production.

Whether you need customizable Vacuum, CVD, or Muffle systems, our technology ensures uniform solvent removal and robust electrode adhesion tailored to your unique research needs.

Ready to optimize your LNMO slurry processing? Contact KINTEK today to consult with our experts on the ideal drying solution for your lab.

Visual Guide

References

- Jong‐Won Lim, Kyung‐Won Park. Enhanced Electrochemical Stability of Solid‐State Electrolyte‐Coated High‐Voltage <scp>L</scp>i<scp>N</scp>i<sub>0.5</sub><scp>M</scp>n<sub>1.5</sub><scp>O</scp><sub>4</sub> Cathodes in Li‐Ion Batteries. DOI: 10.1002/eem2.70025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What function does a high-temperature furnace serve in alumina nanopowder decarbonization? Ensure Purity & Performance

- What role does a high-pressure reactor play in the production of hydrochar? Optimize Biomass Carbonization

- What role does a laboratory precision ventilated oven play in the post-processing of dispersed carbon nanotubes?

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- How does a vacuum drying oven contribute to biodiesel moisture control? Ensure Fuel Quality & Stability

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance

- How does a laboratory furnace work? Master the Heating Mechanisms for Your Lab

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure