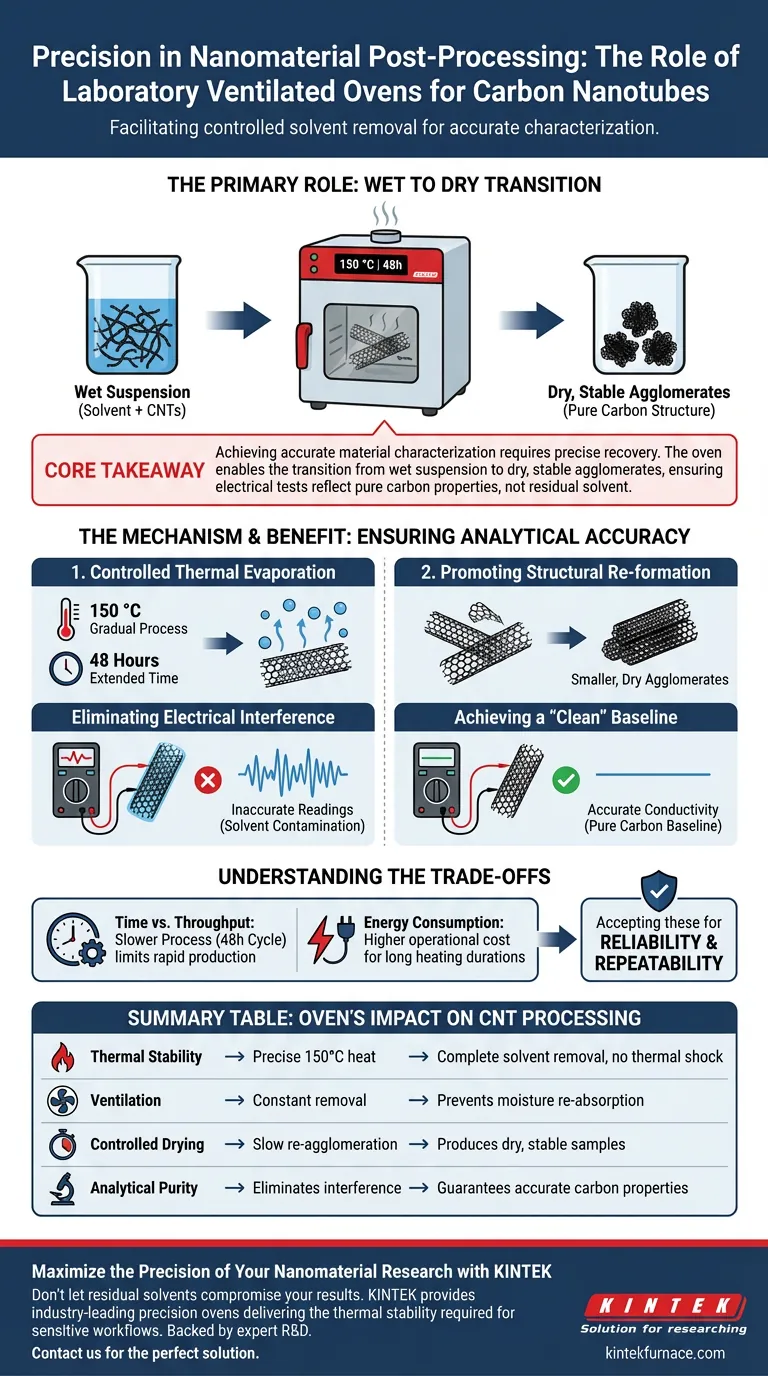

The primary role of a laboratory precision ventilated oven in the processing of dispersed carbon nanotubes is to facilitate the controlled, slow removal of solvents. By maintaining a stable thermal environment, the oven ensures that liquid mediums used during dispersion, such as ethylene glycol, are fully evaporated without compromising the integrity of the nanomaterial.

Core Takeaway Achieving accurate material characterization requires more than just mixing; it requires precise recovery. The ventilated oven enables carbon nanotubes to transition from a wet suspension back into dry, stable agglomerates, ensuring that subsequent electrical testing reflects the properties of the carbon itself, not the residual solvent.

The Mechanism of Solvent Removal

Controlled Thermal Evaporation

The dispersion process often involves suspending carbon nanotubes in solvents to separate them. However, for the material to be useful or testable, this solvent must be removed completely.

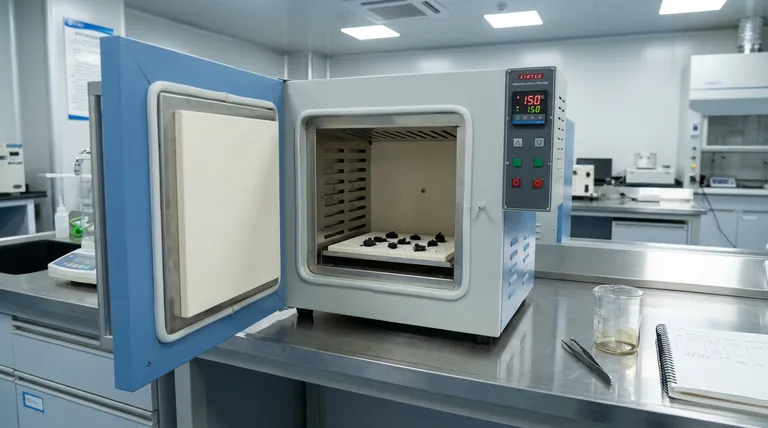

A precision oven is set to specific temperatures, such as 150 °C, to drive this evaporation. Unlike rapid heating methods, this equipment allows for a gradual process, often spanning extended periods like 48 hours.

Promoting Structural Re-formation

As the solvent evaporates, the carbon nanotubes physically change their arrangement. The slow drying process allows the nanotubes to re-form into smaller, dry agglomerates.

This controlled re-agglomeration is essential for handling the material safely and consistently in later stages of production or analysis.

Ensuring Analytical Accuracy

Eliminating Electrical Interference

The most critical reason for using a precision ventilated oven is to protect the validity of downstream testing.

If liquid molecules remain trapped within the nanotube structure, they can act as contaminants. These residuals often alter the conductivity or resistance readings during electrical test results.

Achieving a "Clean" Baseline

By ensuring the total evaporation of solvents like ethylene glycol, the oven guarantees that the material being tested is pure carbon.

This isolation allows researchers and engineers to attribute performance characteristics strictly to the nanotube structure, rather than the dispersion medium.

Understanding the Trade-offs

Time vs. Throughput

The process described is inherently slow. Dedicating 48 hours to a single drying cycle creates a significant bottleneck in workflow throughput.

While this duration ensures quality, it limits the speed of rapid prototyping or high-volume production.

Energy Consumption

Running precision heating equipment for days at a time carries an operational cost.

The trade-off is accepting higher energy usage and longer lead times in exchange for the reliability and repeatability of the dried samples.

Making the Right Choice for Your Goal

To optimize your post-processing workflow, align your oven settings with your specific analytical needs.

- If your primary focus is Electrical Accuracy: Prioritize extended drying times (e.g., 48 hours) to ensure zero solvent interference in conductivity tests.

- If your primary focus is Structural Integrity: Use controlled temperatures (around 150 °C) to allow agglomerates to form naturally without thermal shock.

Precision in drying is not just about removing liquid; it is about defining the baseline for all future data.

Summary Table:

| Feature | Role in CNT Processing | Impact on Results |

|---|---|---|

| Thermal Stability | Precise 150°C heat for 48 hours | Ensures complete solvent removal without thermal shock |

| Ventilation | Constant removal of evaporated solvent | Prevents moisture/chemical re-absorption into nanotubes |

| Controlled Drying | Facilitates slow re-agglomeration | Produces dry, stable samples for safe handling |

| Analytical Purity | Eliminates electrical interference | Guarantees conductivity tests reflect pure carbon properties |

Maximize the Precision of Your Nanomaterial Research

Don’t let residual solvents compromise your electrical testing or material integrity. KINTEK provides industry-leading laboratory precision ovens and high-temperature systems designed to deliver the thermal stability and ventilation required for the most sensitive post-processing workflows.

Backed by expert R&D and world-class manufacturing, KINTEK offers a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working with carbon nanotubes or advanced ceramics, our equipment is fully customizable to meet your unique laboratory needs.

Ensure your results are accurate and repeatable. Contact KINTEK today to find the perfect furnace or oven solution for your lab!

Visual Guide

References

- Bruno Alderete, S. Suárez. Evaluating the effect of unidirectional loading on the piezoresistive characteristics of carbon nanoparticles. DOI: 10.1038/s41598-024-59673-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the primary function of a high-precision drop furnace? Master Flash Smelting Simulation Kinetics

- Why are aluminum alloy castings subjected to high-temperature testing in an industrial blister oven? Reveal Defects

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency

- What is the necessity of the subsequent pyrolysis step in ZnS-CFC preparation? Unlocking High-Performance Carbonization

- What is the purpose of introducing high-purity argon gas into an immersed probe? Enhance Melt Analysis Accuracy

- Why is precise heating rate control necessary during the pyrolysis of bamboo? Optimize Au-NPs/BC Nanocomposite Quality

- How does a continuous furnace differ from a batch furnace? Optimize Your Heat Treatment Process

- Why is a heating system with closed-loop feedback essential for TL analysis? Precision Tips for High-Accuracy Kinetics