Precise heating rate control is the fundamental variable that dictates the structural integrity of bamboo biochar during pyrolysis. Specifically, utilizing a slow ramp rate of approximately 2°C per minute allows for the gradual release of volatile compounds, preventing internal structural collapse and ensuring the material can effectively host gold nanoparticles.

Core Takeaway Controlling the heating rate is not just about temperature management; it is about managing the mechanical stress caused by gas expansion. A slow ramp preserves the bamboo’s natural sieve tube architecture, creating the high specific surface area required for the uniform distribution and stabilization of gold nanoparticles (Au-NPs).

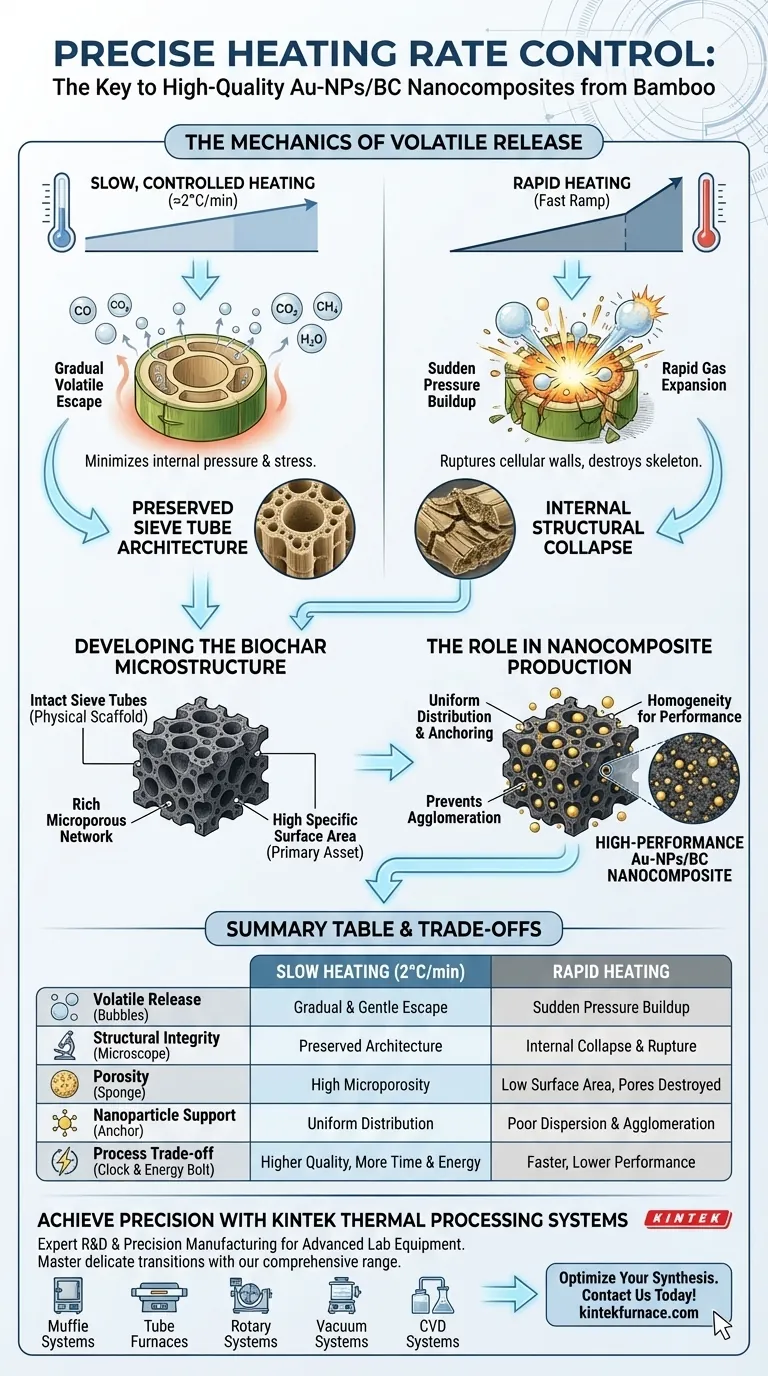

The Mechanics of Volatile Release

Managing Internal Pressure

During pyrolysis, bamboo undergoes thermal decomposition, generating various volatile byproducts. These include carbon monoxide, carbon dioxide, methane, and water vapor.

The Consequence of Rapid Heating

If the temperature rises too quickly, these gases form and expand rapidly within the bamboo matrix. This sudden pressure can rupture the cellular walls, effectively destroying the material's internal skeleton.

The Benefit of Controlled Devolatilization

A precise, slow heating rate (e.g., 2°C per minute) moderates this process. It allows volatiles to escape gently, minimizing physical stress on the carbonizing material.

Developing the Biochar Microstructure

Preserving Sieve Tubes

Bamboo is naturally composed of complex sieve tube structures. Controlled heating is the only way to retain these biological architectures during the transition to biochar.

Creating Microporosity

By preventing structural collapse, the slow release of volatiles facilitates the development of a rich microporous network.

Increasing Specific Surface Area

The preservation of these micropores and sieve tubes results in a biochar (BC) with a significantly high specific surface area. This vast surface area is the primary asset of the material.

The Role in Nanocomposite Production

Providing a Physical Scaffold

For Au-NPs/BC nanocomposites, the biochar serves as the physical support system. The quality of this support is determined entirely by the pyrolysis process.

Ensuring Uniform Distribution

The developed micropores act as anchoring sites for the gold nanoparticles. This prevents the particles from clumping together (agglomeration).

Achieving Homogeneity

Because the sieve tube structure is preserved, the gold nanoparticles can be distributed uniformly throughout the composite. This uniformity is crucial for the material's performance in catalytic or sensing applications.

Understanding the Trade-offs

Process Efficiency vs. Material Quality

The primary trade-off of precise, slow-rate pyrolysis is time. A ramp rate of 2°C per minute significantly extends the duration of the synthesis process compared to faster methods.

Energy Implications

Longer processing times inherently lead to higher energy consumption during the manufacturing phase.

Justifying the Cost

However, for high-performance nanocomposites, this inefficiency is necessary. Rapid heating methods, while faster, yield a low-surface-area char that cannot effectively support or disperse gold nanoparticles.

Optimizing Your Pyrolysis Strategy

To produce high-quality Au-NPs/BC nanocomposites, you must align your thermal processing parameters with your structural goals.

- If your primary focus is Structural Integrity: Adhere strictly to a slow ramp rate (2°C/min) to prevent pore collapse during the off-gassing phase.

- If your primary focus is Nanoparticle Performance: Prioritize the development of micropores over processing speed, as these are required to prevent gold particle aggregation.

By treating the heating rate as a critical architectural tool, you ensure the transformation of raw bamboo into a highly effective, porous nanocarrier.

Summary Table:

| Parameter | Impact of Slow Heating (2°C/min) | Impact of Rapid Heating |

|---|---|---|

| Volatile Release | Gradual & gentle escape | Sudden pressure buildup |

| Structural Integrity | Preserved sieve tube architecture | Internal collapse and rupture |

| Porosity | High microporosity developed | Low surface area, pores destroyed |

| Nanoparticle Support | Uniform distribution & anchoring | Poor dispersion & agglomeration |

| Process Trade-off | Higher quality, more time/energy | Faster, but lower material performance |

Elevate Your Nanocomposite Research with Precision Thermal Processing

Achieving the perfect biochar architecture for Au-NPs/BC nanocomposites requires uncompromising control over heating parameters. KINTEK provides the advanced lab equipment necessary to master these delicate transitions.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need a slow 2°C/min ramp rate for bamboo pyrolysis or a fully customized high-temperature furnace for unique materials, KINTEK ensures your research is supported by reliability and uniform thermal performance.

Ready to optimize your material synthesis? Contact us today to find the ideal thermal solution for your lab's specific needs!

Visual Guide

References

- Synthesis and characterization of gold nanoparticle-mediated bamboo biochar nanocomposite-based electrode and analysis of its electrochemical behavior. DOI: 10.56042/ijbb.v62i2.12109

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- Why is a high-precision furnace required for Li22Sn5 synthesis? Ensure Pure-Phase Alloy Stability

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis

- Why is a high-precision substrate heating system required for BST thin films? Achieve Crystal Growth Success

- What role does a high-temperature curing oven play in lignin-modified wood? Unlock Superior Dimensional Stability

- What are the technical advantages of using a pyrolysis furnace vs. an incinerator? Recover Value from Composites

- Why is a laboratory resistance furnace preferred for Al-5Er-Ti alloys? Achieve High-Purity Homogeneity

- Why is a vacuum freeze dryer used for Vivianite? Optimize Your LFP Synthesis with Superior Precursor Integrity