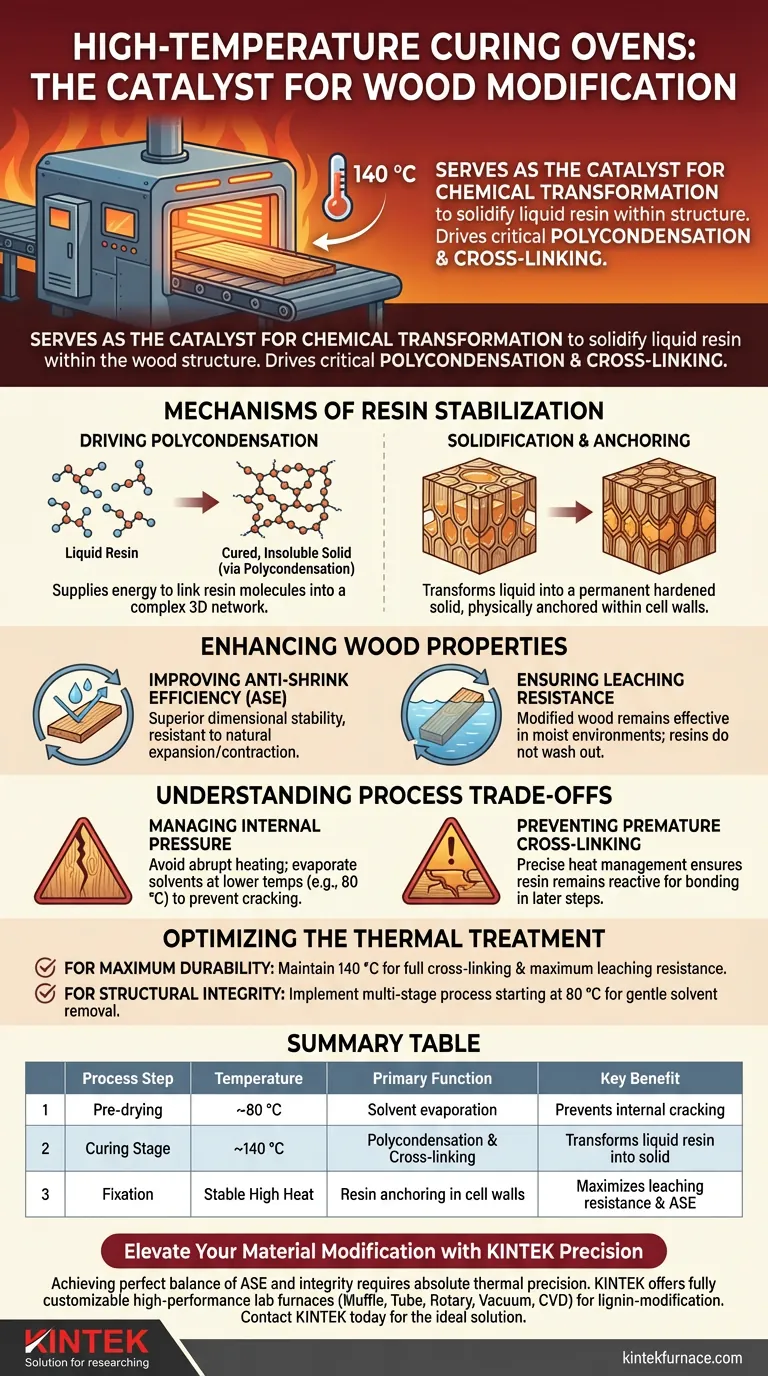

A high-temperature curing oven serves as the catalyst for chemical transformation, creating a stable thermal environment (typically around 140 °C) to solidify liquid resin within the wood structure. This heat drives critical polycondensation and cross-linking reactions, converting the impregnated lignin-modified phenolic resin into an insoluble solid anchored firmly inside the wood's cell walls.

The oven is not merely a drying device; it is a chemical reactor that locks resin into the wood structure to maximize dimensional stability and prevent the treatment from washing out over time.

Mechanisms of Resin Stabilization

Driving Polycondensation

The primary function of the oven is to supply the energy required to initiate and sustain polycondensation.

At temperatures near 140 °C, the resin molecules undergo a chemical reaction where they link together. This process creates a complex, three-dimensional network within the wood.

Solidification and Anchoring

Before this thermal treatment, the resin exists as a liquid within the wood structure.

The curing oven transforms this liquid into a permanent, hardened solid. This solid structure physically anchors itself within the cell walls, becoming an integral part of the composite material.

Enhancing Wood Properties

Improving Anti-Shrink Efficiency (ASE)

One of the most significant outcomes of high-temperature curing is the improvement of Anti-Shrink Efficiency (ASE).

By bulking the cell walls with cured resin, the wood becomes resistant to natural expansion and contraction. This results in superior dimensional stability compared to untreated timber.

Ensuring Leaching Resistance

Without proper curing, resins can remain soluble and easily wash out in humid or wet environments.

The high-temperature fixation ensures leaching resistance, meaning the protective properties of the modified wood remain effective even when exposed to moisture.

Understanding Process Trade-offs

Managing Internal Pressure

While high heat is necessary for curing, applying it too abruptly can be destructive.

Solvents must be evaporated at lower temperatures (such as 80 °C) before full curing. Failing to do so can generate excessive internal vapor pressure, leading to cracking or structural failure within the wood.

Preventing Premature Cross-linking

Temperature control is also critical for preserving the resin's utility for downstream processes.

If the resin cross-links too early—before steps like veneer stacking or hot-pressing—it loses the reactivity needed to bond layers together. Precise heat management ensures the resin remains viable for the final manufacturing stages.

Optimizing the Thermal Treatment

To achieve the best results with lignin-modified phenolic resins, you must balance curing requirements with material integrity.

- If your primary focus is Maximum Durability: Ensure the oven reaches and maintains 140 °C to achieve full cross-linking and maximum leaching resistance.

- If your primary focus is Structural Integrity: Implement a multi-stage process starting at 80 °C to remove solvents gently and prevent internal pressure cracks.

The difference between a failed batch and a high-performance product lies in the precision of your thermal control strategy.

Summary Table:

| Process Step | Temperature | Primary Function | Key Benefit |

|---|---|---|---|

| Pre-drying | ~80 °C | Solvent evaporation | Prevents internal cracking and vapor pressure |

| Curing Stage | ~140 °C | Polycondensation & Cross-linking | Transforms liquid resin into insoluble solid |

| Fixation | Stable High Heat | Resin anchoring in cell walls | Maximizes leaching resistance and ASE |

Elevate Your Material Modification with KINTEK Precision

Achieving the perfect balance of Anti-Shrink Efficiency (ASE) and structural integrity requires absolute thermal precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance lab high-temp furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique lignin-modification and resin-curing requirements.

Don't let imprecise heating compromise your wood composite quality. Contact KINTEK today to find the ideal furnace solution for your lab and ensure maximum leaching resistance for your advanced materials.

Visual Guide

References

- Johannes Karthäuser, Holger Militz. Utilizing pyrolysis cleavage products from softwood kraft lignin as a substitute for phenol in phenol-formaldehyde resins for modifying different wood species. DOI: 10.1007/s00107-024-02056-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does the temperature of the annealing process specifically influence the luminescence properties of ZnSe? Guide

- How are expansion compensation devices modeled in high-temp simulations? Enhance Accuracy with Self-Compensation Modeling

- What role does temperature control play in biomass pyrolysis for biochar? Achieve Optimal Pore Structure & Yield

- What is the role of a water-cooled solid end? Master Thermal Gradients in Directional Solidification

- How does plasma nitriding equipment improve the performance of titanium alloys in seawater? Boost Marine Durability

- What is the purpose of adding calcium fluoride (CaF2) in magnesium production? Accelerate Your Vacuum Carbothermal Reduction

- How does a precision carbon dioxide gas flow control system influence the precipitation of high-purity lithium carbonate?

- What are the advantages of using a vacuum drying oven for ZIF67/MXene? Protect Your Composite Integrity