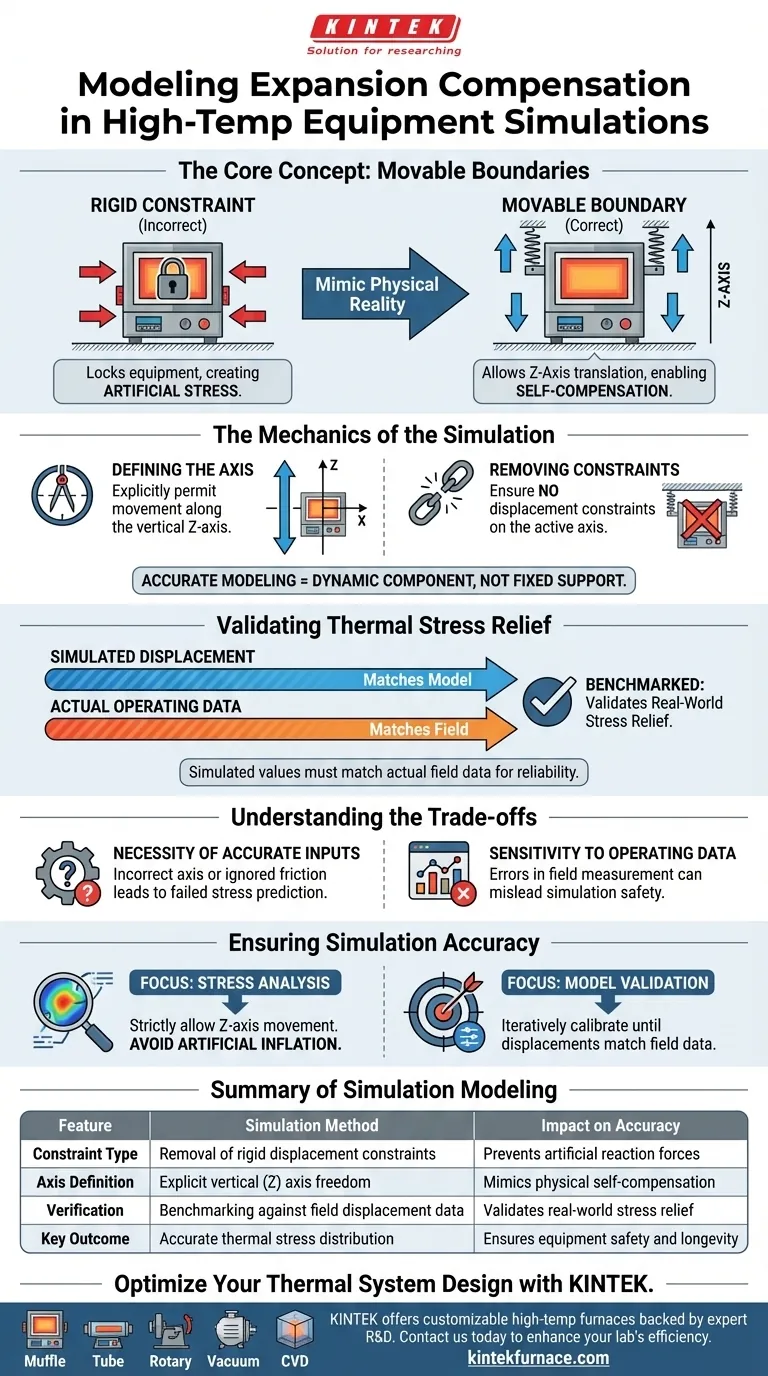

In mechanical constraint simulations, expansion compensation devices like spring suspension systems are modeled by explicitly permitting movement along a specific directional axis, typically the vertical (Z) axis. Rather than applying rigid displacement constraints that lock the equipment in place, the finite element model is defined to allow free translation in this direction to mimic physical reality.

By removing rigid constraints on the suspension axis, the model accurately simulates the equipment's "self-compensation" capability. This ensures that the calculated thermal stresses reflect the actual relief provided by the suspension system during operation.

The Mechanics of the Simulation

Defining the Axis of Movement

To replicate the behavior of high-temperature equipment, the simulation must account for directional freedom.

In the finite element model, the boundary conditions for the spring suspension are set to allow movement specifically along the vertical Z-axis. This distinguishes the suspension points from fixed anchor points, which would otherwise restrict all motion.

Removing Displacement Constraints

The key to accurate modeling is the absence of artificial restrictions.

The simulation setup must ensuring that no displacement constraints are imposed on the suspension's active axis. This prevents the mathematical model from generating artificial reaction forces that would not exist in the real-world physical system.

Validating Thermal Stress Relief

Simulating Self-Compensation

High-temperature equipment expands naturally when heated.

By modeling the suspension as a movable boundary, the simulation captures the equipment's ability to self-compensate. This confirms that the equipment can expand without generating excessive internal stresses that would occur if it were rigidly constrained.

Benchmarking Against Real Data

The reliability of the simulation depends on verification.

Engineers assess the effectiveness of the model by comparing the simulated displacement values directly with actual operating data. If the simulation moves the same amount as the real equipment, the model is considered a valid predictor of thermal stress relief.

Understanding the Trade-offs

The Necessity of Accurate Inputs

While this modeling approach is realistic, it relies heavily on the quality of the boundary definitions.

If the axis of movement is defined incorrectly, or if friction is ignored where it shouldn't be, the model will fail to predict the true stress distribution.

Sensitivity to Operating Data

The validation process is only as good as the field data available.

Because the model is validated by matching actual operating data, any errors in field measurement can lead to a false sense of security regarding the safety of the simulation results.

Ensuring Simulation Accuracy

To effectively model expansion compensation in your projects:

- If your primary focus is Stress Analysis: Ensure your boundary conditions strictly allow movement along the vertical Z-axis to avoid artificially inflating stress values.

- If your primary focus is Model Validation: Calibrate your simulation by iteratively adjusting parameters until the simulated displacements match your recorded field data.

Accurate modeling requires treating the suspension not as a fixed support, but as a dynamic component that breathes with the equipment.

Summary Table:

| Feature | Simulation Method | Impact on Accuracy |

|---|---|---|

| Constraint Type | Removal of rigid displacement constraints | Prevents artificial reaction forces |

| Axis Definition | Explicit vertical (Z) axis freedom | Mimics physical self-compensation |

| Verification | Benchmarking against field displacement data | Validates real-world stress relief |

| Key Outcome | Accurate thermal stress distribution | Ensures equipment safety and longevity |

Optimize Your Thermal System Design with KINTEK

Ensure your high-temperature equipment is built for durability and performance. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temp furnaces are fully customizable to accommodate unique expansion compensation needs and complex mechanical constraints.

Ready to enhance your lab's thermal processing efficiency? Contact us today to discuss how our customizable systems can meet your exact research and production requirements.

Visual Guide

References

- Nenghong Zheng, Ye Chen. Numerical Simulation Research on Screen Superheater of Supercritical Circulating Fluidized Bed Boiler. DOI: 10.54691/czsm3b20

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a high vacuum deposition system ensure thin film quality? Purity Through Advanced Pumping

- What is the function of a laboratory drying oven in the preparation of solid bismuth molybdate materials? Expert Tips

- How does temperature control affect nanoporous copper dealloying? Master Pore Uniformity and Size

- What is the primary purpose of 24-hour wet milling for SSBSN ceramics? Achieve Atomic-Scale Homogeneity

- What is induction heating and what materials can it be used on? A Guide to Fast, Precise Heating

- What role does a belt-type rapid sintering furnace play in forming metal contacts? Optimize Solar Cell Efficiency

- How does the availability of specialized furnace systems benefit chemical research? Optimize Your Thermal Processing

- What is the function of a drying oven during the chemical activation of biochar? Optimize Your Porous Carbon Structure