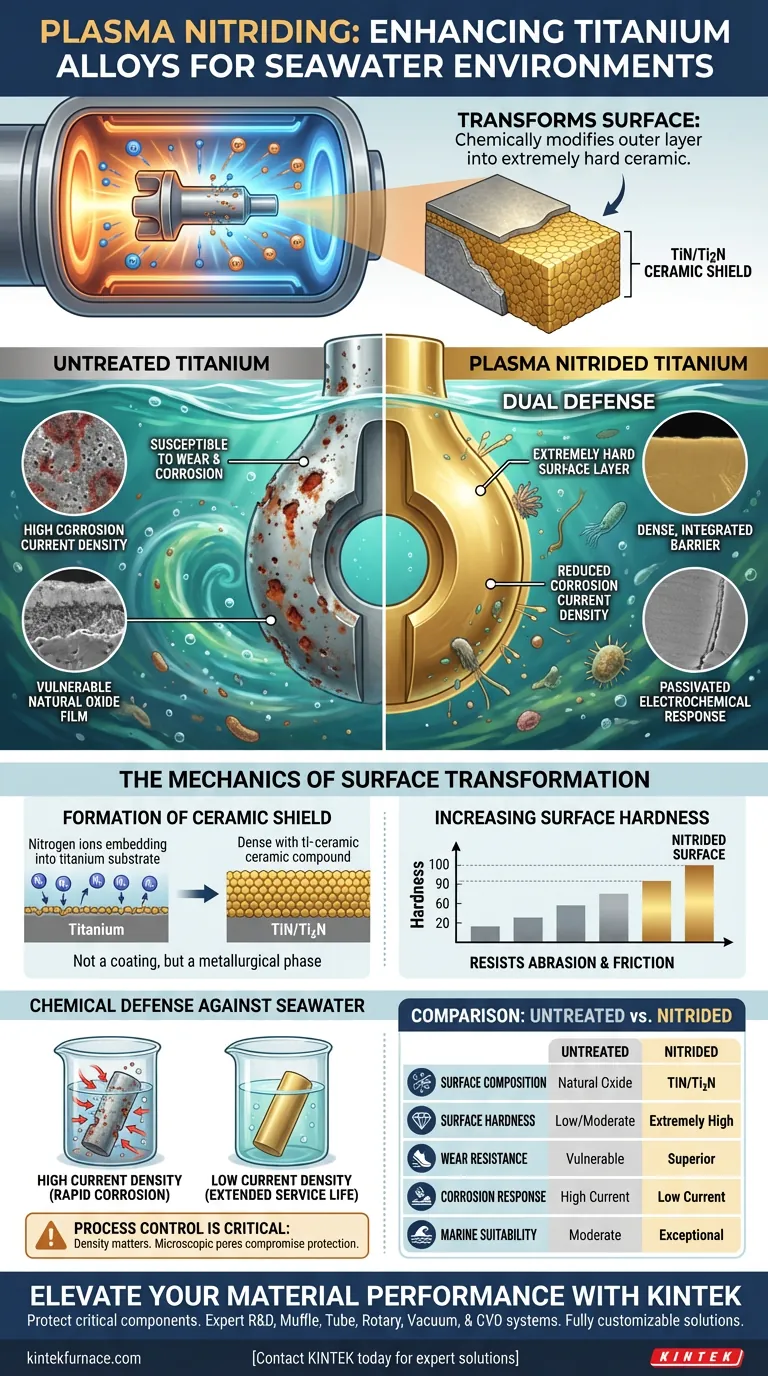

Plasma nitriding equipment transforms the surface of titanium alloys by chemically modifying the outer layer to form a dense, extremely hard ceramic compound known as titanium nitride (TiN/Ti2N). This process directly addresses the vulnerabilities of titanium in marine settings by significantly increasing wear resistance and fundamentally altering the material's electrochemical response to corrosive seawater.

The core advantage lies in the creation of a titanium nitride barrier. This layer effectively reduces corrosion current density and hardens the surface, providing a dual defense against the chemical attack and physical abrasion common in seawater environments.

The Mechanics of Surface Transformation

Formation of the Ceramic Shield

Plasma nitriding equipment does not simply paint a coating onto the alloy. Instead, it introduces nitrogen ions into the surface of the titanium to create a new metallurgical phase.

This results in the formation of titanium nitride (TiN/Ti2N). This is a dense ceramic layer that integrates with the substrate, rather than just sitting on top of it.

Increasing Surface Hardness

While titanium is known for its high strength-to-weight ratio, untreated titanium alloys can be susceptible to surface wear.

The plasma nitriding process generates an extremely hard surface layer. This hardness is critical for components that face abrasive particles suspended in seawater or physical friction from operation.

Chemical Defense Against Seawater

Altering Electrochemical Properties

Corrosion is fundamentally an electrochemical process. The presence of the nitrided layer changes how the titanium interacts with electrolytes like seawater.

By altering these electrochemical properties, the equipment effectively "passivates" the surface more robustly than the natural oxide film found on untreated titanium.

Reducing Corrosion Current Density

The most significant metric for marine performance in this context is corrosion current density. High current density indicates rapid corrosion.

The nitrided layer effectively reduces this density in corrosive media. This reduction slows down the degradation process, ensuring the alloy maintains its structural integrity over a longer service life in extreme environments.

Understanding the Constraints

Process Control is Critical

The effectiveness of this protection relies entirely on the density of the ceramic layer.

If the equipment is not calibrated to produce a dense TiN/Ti2N layer, microscopic pores could allow seawater to penetrate the coating. This would compromise the enhanced corrosion resistance described above.

Surface vs. Core Properties

It is important to remember that this is a surface modification technique.

While the outer layer becomes a hard ceramic, the core of the material retains the original properties of the titanium alloy. The benefit is strictly localized to the interface between the metal and the seawater.

Evaluating Plasma Nitriding for Marine Applications

To determine if this process aligns with your engineering requirements, consider the specific stresses your components will face.

- If your primary focus is Wear Resistance: The formation of the extremely hard TiN/Ti2N layer will protect moving parts from abrasion and friction.

- If your primary focus is Corrosion Longevity: The reduction in corrosion current density offers a significant extension of service life for static structures submerged in seawater.

By leveraging plasma nitriding, you convert a standard titanium alloy into a composite system capable of withstanding the dual threats of chemical corrosion and physical wear.

Summary Table:

| Feature | Untreated Titanium Alloy | Plasma Nitrided Titanium |

|---|---|---|

| Surface Composition | Natural Oxide Film | Titanium Nitride (TiN/Ti2N) Layer |

| Surface Hardness | Low to Moderate | Extremely High (Ceramic) |

| Wear Resistance | Vulnerable to abrasion | Superior resistance to physical wear |

| Corrosion Response | High Current Density | Low Current Density (Reduced Degradation) |

| Marine Suitability | Moderate | Exceptional (Dual Defense) |

Elevate Your Material Performance with KINTEK

Protect your critical components from the harshest marine conditions. Backed by expert R&D and manufacturing, KINTEK offers cutting-edge Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature furnace solutions designed for advanced surface treatments like plasma nitriding.

Whether you are looking to enhance wear resistance or ensure long-term corrosion protection, our equipment is fully customizable to meet your unique metallurgical needs. Don't let seawater compromise your project’s integrity—partner with KINTEK for superior material durability.

Ready to transform your titanium alloys? Contact KINTEK today for expert solutions!

Visual Guide

References

- Kang Gao, Pinghu Chen. Overview of Surface Modification Techniques for Titanium Alloys in Modern Material Science: A Comprehensive Analysis. DOI: 10.3390/coatings14010148

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- How does a continuous argon flow heating chamber aid CMF testing? Ensure Pure Thermal Analysis

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- Why must Ba1-xCaxTiO3 ceramic samples undergo a high-temperature silver-firing process? Ensure Accurate Dielectric Data

- What role does precise temperature control play in nuclear waste leaching tests? Ensure Accurate Safety Evaluations

- Why is annealing considered a core process in perovskite solar cell manufacturing? Unlock Peak Efficiency

- What is the function of a high-pressure reactor in hydrothermal carbonization? Master Biomass Conversion Efficiency

- What are the specific temperature control requirements for alpha-SiC growth? Master the 1700°C Thermal Threshold