To successfully grow hexagonal alpha-Silicon Carbide (alpha-SiC) crystals, your high-temperature reactor must maintain a precise and stable environment above 1700 degrees Celsius. This thermal threshold is non-negotiable for producing alpha-phase variants, such as 4H-SiC and 6H-SiC.

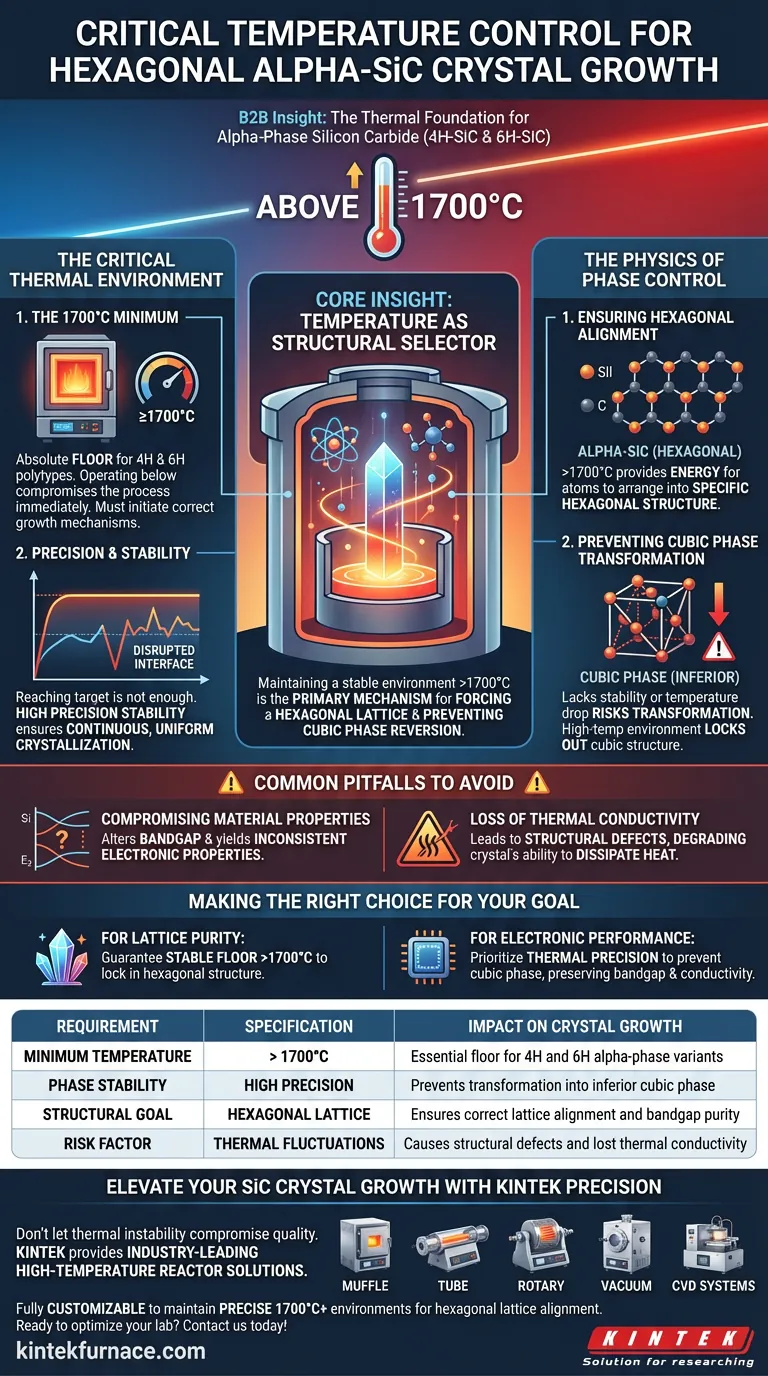

Core Insight: Temperature in SiC growth is not merely a catalyst; it is a structural selector. Maintaining a stable environment above 1700°C is the primary mechanism for forcing the material into a hexagonal lattice and preventing it from reverting to an inferior cubic phase.

The Critical Thermal Environment

The 1700°C Minimum

For alpha-phase Silicon Carbide, specifically the 4H and 6H polytypes, 1700°C serves as the absolute floor for viable crystal growth.

Operating below this temperature compromises the process immediately. The reactor must be capable of reaching and sustaining temperatures exceeding this figure to initiate the correct growth mechanisms.

Precision and Stability

Reaching the target temperature is not enough; the reactor must maintain it with high precision.

Fluctuations in the thermal environment can disrupt the growth interface. Stability is essential to ensure continuous, uniform crystallization throughout the production cycle.

The Physics of Phase Control

Ensuring Hexagonal Alignment

The primary reason for this high thermal requirement is lattice alignment.

At temperatures above 1700°C, the silicon and carbon atoms possess the energy required to arrange themselves into the specific hexagonal structure that defines alpha-SiC.

Preventing Cubic Phase Transformation

If the temperature drops or lacks stability, the crystal structure is at risk of transforming into the cubic phase.

This phase change is a failure mode for alpha-SiC growth. The high-temperature environment effectively locks out the cubic structure, forcing the crystal to maintain its hexagonal identity.

Common Pitfalls to Avoid

Compromising Material Properties

Failing to maintain the required temperature profile has direct downstream effects on the material's performance.

Specifically, the transformation into the cubic phase alters the bandgap of the material. A reactor that cannot hold >1700°C yields a material with inconsistent electronic properties.

Loss of Thermal Conductivity

Beyond the bandgap, thermal stability is critical for preserving thermal conductivity characteristics.

Inconsistent heating leads to structural defects or mixed phases, which degrade the crystal's ability to dissipate heat—one of the primary advantages of using SiC in the first place.

Making the Right Choice for Your Goal

To ensure your reactor setup meets the necessary criteria for high-quality SiC production, prioritize your system specifications based on the following:

- If your primary focus is Lattice Purity: Ensure your control systems can guarantee a stable floor above 1700°C to lock in the hexagonal structure.

- If your primary focus is Electronic Performance: Prioritize thermal precision to prevent cubic phase transformation, thereby preserving the specific bandgap and thermal conductivity required for your application.

Mastering the thermal environment is the single most critical factor in defining the physical and electronic identity of your Silicon Carbide crystals.

Summary Table:

| Requirement | Specification | Impact on Crystal Growth |

|---|---|---|

| Minimum Temperature | > 1700°C | Essential floor for 4H and 6H alpha-phase variants |

| Phase Stability | High Precision | Prevents transformation into inferior cubic phase |

| Structural Goal | Hexagonal Lattice | Ensures correct lattice alignment and bandgap purity |

| Risk Factor | Thermal Fluctuations | Causes structural defects and lost thermal conductivity |

Elevate Your SiC Crystal Growth with KINTEK Precision

Don't let thermal instability compromise your semiconductor quality. KINTEK provides industry-leading high-temperature reactor solutions specifically engineered for the rigorous demands of alpha-Silicon Carbide production.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to maintain the precise 1700°C+ environments your hexagonal lattice alignment requires. Whether you are prioritizing lattice purity or electronic performance, our systems ensure the stability needed to lock out cubic phase transformations.

Ready to optimize your lab's high-temp capabilities? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Qingyuan Yu. Comparative Analysis of Sic and Gan: Third-Generation Semiconductor Materials. DOI: 10.54097/2q3qyj85

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is high raw material purity essential for magnesium alloy research? Ensure Precise Thermodynamic Data Quality

- What role does an RTA system play in processing SiN thin films? Unlock High-Performance Quantum & Optical Materials

- Why is a jaw crusher used for initial magnesite ore crushing? Maximize Efficiency & Protect Your Mill

- What factors are assessed during the evaluation for an Industrial Furnace project? Optimize Your Thermal Process

- Why is uniform heating important in industrial processes? Ensure Quality and Efficiency in Manufacturing

- What is the significance of the vacuum oven drying process in the preparation of MnO@WAC electrode sheets? Expert Guide

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- Why is the mechanical mixing of precursor powders necessary for ITO thin films? Guide to Precision Growth