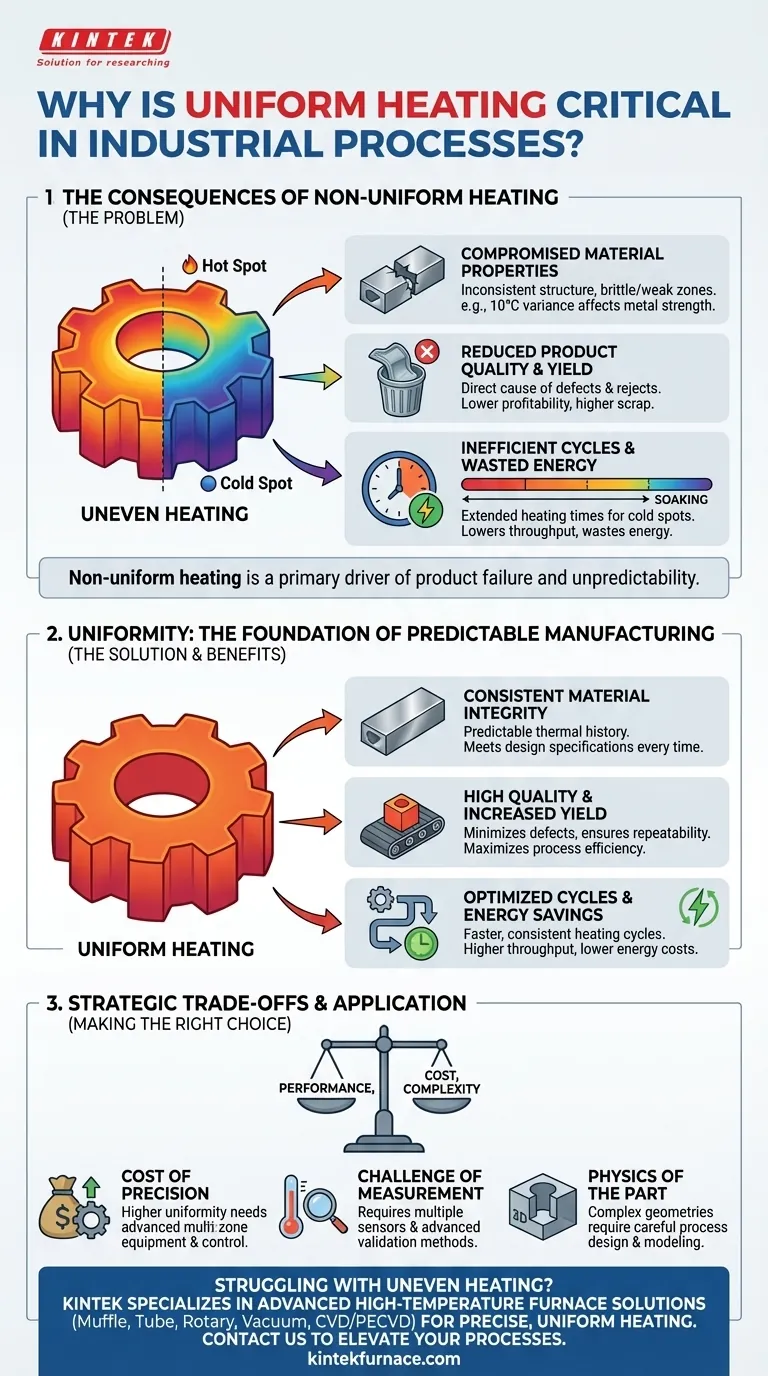

Uniform heating is crucial in industrial settings because it guarantees that every part of a product experiences the same thermal conditions. This consistency is the foundation of predictable and repeatable manufacturing, preventing defects, ensuring material integrity, and maximizing the efficiency of the entire process.

Non-uniform heating is not merely an inefficiency; it is a primary driver of product failure, inconsistent quality, and unpredictable outcomes. Achieving thermal uniformity is the most direct way to exert control over a process, ensuring the final product meets its design specifications every time.

The Consequence of Thermal Gradients

The goal of any industrial heating process is to induce a specific physical or chemical change. When heat is applied unevenly, that change happens at different rates in different locations, creating a cascade of problems.

Compromised Material Properties

The physical structure of a material is often defined by its thermal history. Hot spots and cold spots create inconsistencies that permanently weaken the final product.

In metal heat treating, for example, a 10°C variance can be the difference between a strong, ductile part and a brittle one. A cold spot might not undergo the required phase transformation, creating a soft area that will fail under stress.

Reduced Product Quality and Yield

Inconsistent heating is a direct cause of rejected parts. This has a significant impact on process yield and profitability.

A common example is in plastics or composites, where uneven curing can lead to warping, internal stresses, or surface blemishes. Each warped part is scrap, wasting material, energy, and machine time.

Inefficient Cycles and Wasted Energy

To compensate for a known cold spot, operators are often forced to extend the heating cycle time, a practice known as "soaking." The goal is to give the coldest area enough time to reach the target temperature.

This approach is profoundly inefficient. It forces the rest of the batch to be held at temperature for longer than necessary, wasting a significant amount of energy and reducing the overall throughput of the equipment.

Where Uniformity is Non-Negotiable

While important everywhere, thermal uniformity is the single most critical variable in many high-precision industries. The success or failure of the entire operation hinges on it.

Semiconductor Manufacturing

During wafer processing, hundreds of delicate steps like deposition and etching are performed. The performance of the resulting microchips is directly tied to the uniformity of temperature across the entire silicon wafer, often with tolerances of less than ±1°C.

Aerospace and Medical Components

For critical components like turbine blades or medical implants, material failure is not an option. Uniform heat treatment ensures consistent grain structure and strength, guaranteeing the part will perform as designed under extreme conditions and meet stringent safety standards.

Curing and Coating Processes

From the paint on a car to the adhesive bonding a composite wing, the curing process must be uniform. Incomplete curing in one area leads to a weak point, risking delamination, corrosion, or structural failure over the product's lifespan.

Understanding the Trade-offs

Achieving perfect thermal uniformity is an engineering challenge that involves balancing performance, cost, and complexity. It is not simply about turning up the heat.

The Cost of Precision

Higher uniformity requires more advanced equipment. This can include multi-zone heaters for independent control, high-velocity convection fans for better heat distribution, or more sophisticated PID controllers and sensors. This upfront investment can be substantial.

The Challenge of Measurement

You cannot control what you cannot measure. Verifying uniformity requires multiple thermocouples placed throughout the product or workspace, or non-contact methods like thermal imaging. This adds complexity to process setup and validation.

The Physics of the Part

The geometry of the product itself can work against you. Complex shapes with thick and thin sections will naturally heat at different rates due to thermal conduction. Overcoming this requires careful process design and advanced modeling.

Making the Right Choice for Your Goal

Evaluating your process heating needs should be driven by the end goal. Use these principles to guide your decisions on equipment and process design.

- If your primary focus is ultimate product quality and consistency: Invest in multi-zone heating control and a comprehensive sensor or thermal imaging package to actively eliminate temperature gradients.

- If your primary focus is maximizing throughput and energy efficiency: Prioritize systems with superior heat transfer mechanisms, like high-flow convection, to reduce cycle times and eliminate wasteful "soaking" periods.

- If your primary focus is controlling costs on a new process: Begin with thermal modeling and simulation to understand the natural heating profile of your part and determine the minimum required level of uniformity to meet specifications, avoiding over-engineering.

Ultimately, mastering uniform heating transforms a critical processing variable into a reliable and predictable constant.

Summary Table:

| Aspect | Impact of Uniform Heating |

|---|---|

| Material Properties | Prevents hot/cold spots, ensuring consistent strength and avoiding brittleness |

| Product Quality | Reduces rejections, warping, and defects for higher yield |

| Process Efficiency | Eliminates energy waste from extended cycles, improving throughput |

| Key Industries | Critical in semiconductors, aerospace, and curing processes for precision |

Struggling with uneven heating in your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to deliver precise, uniform heating that enhances your experimental outcomes and boosts efficiency. Our strong deep customization capability ensures we can meet your specific requirements, helping you achieve consistent results and reduce waste. Don't let thermal inconsistencies hold you back—contact us today to discuss how KINTEK can elevate your industrial processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety