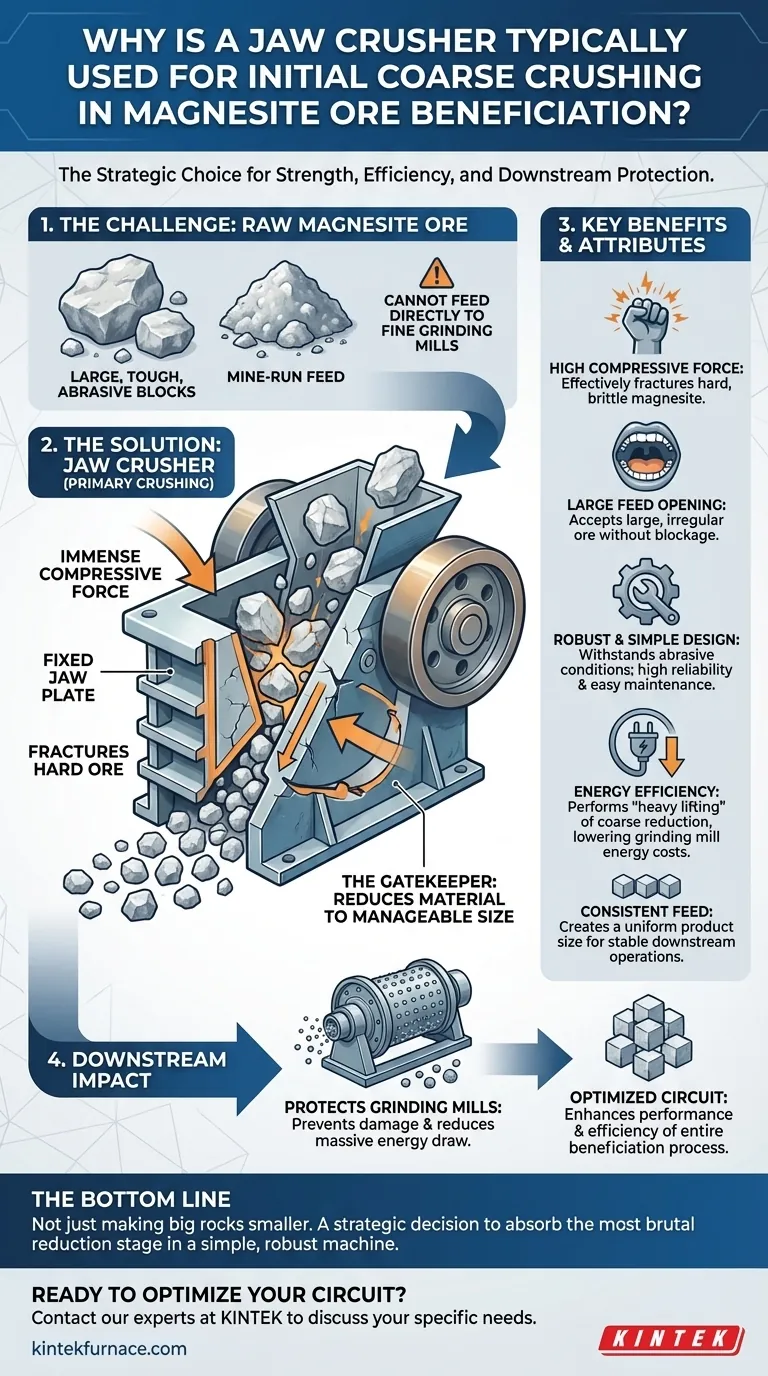

In magnesite ore processing, a jaw crusher is the designated equipment for the initial coarse crushing stage due to its ability to apply immense compressive force. It is specifically designed to break down the large, tough, and often abrasive blocks of raw ore delivered from the mine. This first step is essential for reducing the material to a manageable size, which in turn lowers the energy consumption and mechanical stress on the subsequent, more sensitive grinding equipment.

The use of a jaw crusher is a strategic decision in mineral processing. It is not merely about making big rocks smaller; it's about absorbing the most brutal stage of size reduction in a simple, robust machine to protect more complex equipment and optimize the energy efficiency of the entire beneficiation circuit.

The Principle of Primary Crushing

Primary crushing is the first and most mechanically demanding step in the comminution process, which is the overall reduction of particle size. Its role is fundamental to the success of all downstream operations.

Why Coarse Crushing is Non-Negotiable

You cannot feed large, irregular boulders from a mine directly into a fine grinding mill. The mill is not designed to handle such sizes and would be catastrophically damaged.

Primary crushers act as the gatekeepers of the processing plant, ensuring all material is reduced to a predictable and manageable size for the next stage.

The Goal: Preparing for Liberation

The ultimate objective of crushing and grinding is to "liberate" the valuable magnesite from the surrounding waste rock, known as gangue.

By breaking the ore along its natural fracture planes, the jaw crusher begins this liberation process, making it easier for subsequent grinding stages to fully separate the minerals.

Why the Jaw Crusher is the Right Tool for the Job

While other crushers exist, the jaw crusher's specific design characteristics make it uniquely suited for the primary crushing of hard ores like magnesite.

A Mechanism Built for Compressive Strength

A jaw crusher operates with one fixed jaw plate and one moving jaw plate. This simple design creates a V-shaped crushing chamber.

The moving jaw exerts enormous compressive force on the ore, fracturing it effectively. This direct pressure is ideal for hard, brittle materials like magnesite.

Handling Large and Irregular Feed

Jaw crushers are defined by a large feed opening, or gape. This allows them to accept very large, unevenly shaped blocks of ore without blockage, a critical requirement for a primary crusher.

Simplicity and Durability

Compared to other primary crusher types, jaw crushers are mechanically simple and exceptionally robust. Their rugged construction allows them to withstand the high-impact, abrasive environment of a mine site with high reliability and relatively straightforward maintenance.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. Understanding the jaw crusher's limitations clarifies its specific role in the circuit.

Not Designed for Fine Reduction

A jaw crusher is a specialist in coarse crushing. It has a limited reduction ratio, meaning it can only make the ore a few times smaller than its feed size.

It cannot produce the fine particles required for separation methods like flotation; that is the job of secondary crushers and grinding mills.

Inefficient with Sticky Materials

The compressive action of a jaw crusher can cause issues with soft or sticky ores, which may compact and clog the crushing chamber. This limitation reinforces why it is an excellent choice for hard, non-sticky magnesite.

The Impact on Downstream Efficiency

The primary crusher's performance has a significant ripple effect throughout the entire processing plant, particularly on energy usage and throughput.

Reducing the Burden on Grinding Mills

Grinding is by far the most energy-intensive part of mineral processing. Every unit of size reduction achieved in the crushing stage is a unit of energy saved in the grinding stage.

The jaw crusher performs the "heavy lifting" of initial size reduction far more economically than a grinding mill could, drastically lowering overall plant energy costs.

Creating a Consistent Feed for Secondary Stages

By transforming unpredictable, mine-run ore into a product with a controlled top size, the jaw crusher provides a consistent and manageable feed for secondary crushing or milling circuits. This stability improves the performance and efficiency of all subsequent equipment.

Making the Right Choice for Your Goal

Selecting a jaw crusher for primary duty is an engineering decision rooted in the characteristics of the ore and the operational goals of the plant.

- If your primary focus is handling hard, abrasive, large-sized feed: The jaw crusher is the default choice due to its high compressive force and robust design.

- If your primary focus is maximizing plant energy efficiency: Using a jaw crusher for coarse reduction is a critical first step to lower the massive energy draw of downstream grinding circuits.

- If your primary focus is achieving high throughput with minimal downtime: The mechanical simplicity and durability of a jaw crusher make it a reliable workhorse for the demanding primary crushing stage.

Ultimately, the jaw crusher's role is to reliably and economically absorb the initial, brutal impact of size reduction, setting the entire magnesite beneficiation process up for success.

Summary Table:

| Key Attribute | Benefit for Magnesite Ore Processing |

|---|---|

| High Compressive Force | Effectively fractures hard, brittle magnesite ore. |

| Large Feed Opening | Accepts large, irregular mine-run ore without blockage. |

| Robust & Simple Design | Withstands abrasive conditions with high reliability and easy maintenance. |

| Energy Efficiency | Performs 'heavy lifting' of coarse reduction, drastically lowering grinding mill energy costs. |

| Consistent Feed | Creates a uniform product size for stable secondary crushing and grinding operations. |

Ready to Optimize Your Magnesite Beneficiation Circuit?

Choosing the right primary crusher is the first critical step toward a more efficient and profitable operation. Our team at KINTEK can help you select the ideal robust jaw crusher to handle your toughest ore, protect your downstream equipment, and significantly reduce your energy consumption.

We provide solutions for: Mining operations and mineral processing plants focused on hard, abrasive ores like magnesite.

Our expertise includes: Designing and supplying durable, high-performance crushers backed by expert engineering and manufacturing.

Contact our experts today to discuss your specific needs and discover how our reliable crushing solutions can enhance your entire beneficiation process.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries