A Vacuum Induction Melting (VIM) furnace is essential because it combines electromagnetic induction heating with a high-vacuum environment to isolate and purify molten metals. This specific configuration actively removes gaseous impurities such as oxygen, nitrogen, and hydrogen, while simultaneously preventing the oxidation of reactive elements. The result is an ultra-clean, chemically precise material required for critical applications in aerospace and high-purity semiconductors.

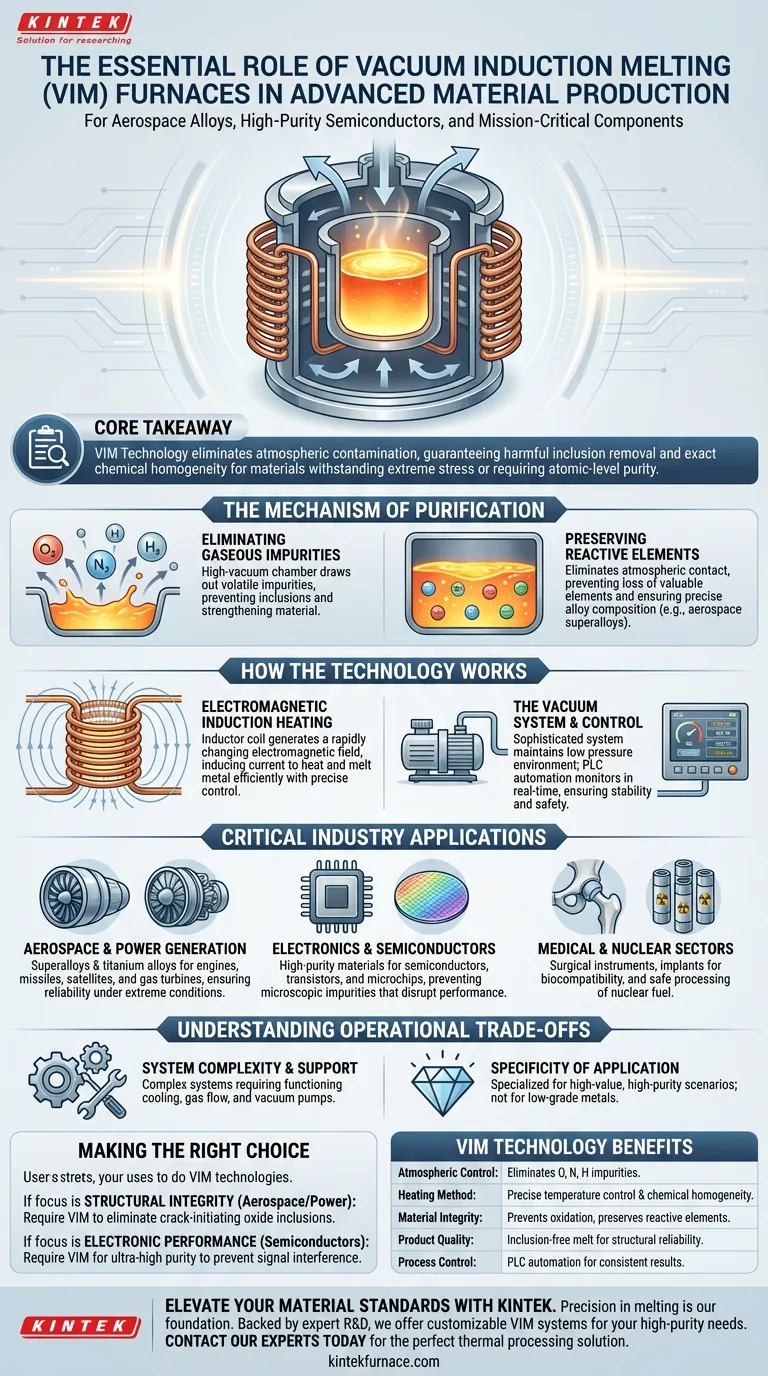

Core Takeaway: VIM technology addresses the critical challenge of atmospheric contamination in metallurgy. By processing materials in a vacuum, it guarantees the elimination of harmful inclusions and ensures exact chemical homogeneity, which is mandatory for components that must withstand extreme stress or require atomic-level purity.

The Core Mechanism of Purification

Eliminating Gaseous Impurities

The primary function of the VIM furnace is to create a pristine environment for melting. By operating within a high-vacuum chamber, the system facilitates the active removal of volatile impurities.

Gases such as oxygen, nitrogen, and hydrogen are drawn out of the molten metal and ejected via the vacuum pumping system. This prevents the formation of inclusions that would otherwise weaken the material's mechanical properties.

Preserving Reactive Elements

Standard melting processes often lead to the loss of valuable, easily oxidizable elements due to interaction with the air. VIM furnaces inhibit this loss by eliminating atmospheric contact.

This protection allows for the precise control of the alloy's chemical composition. It ensures that the final product retains the exact ratio of elements necessary for high-performance standards, such as those found in aerospace-grade superalloys.

How the Technology Works

Electromagnetic Induction Heating

The heating source in a VIM furnace is an inductor, typically a copper coil, which generates a rapidly changing electromagnetic field. This field induces an electrical current within the metal itself, causing it to heat up and melt efficiently.

This method allows for precise temperature control, ensuring consistent results across different batches. Because the heat is generated directly within the material, the process is highly energy-efficient compared to indirect heating methods.

The Vacuum System and Control

A sophisticated vacuum system, comprising pumps and a chamber, maintains the necessary low-pressure environment throughout the melting and casting process. This system is critical for preventing re-contamination during the liquid phase.

Advanced electrical controls, often managed by a programmable logic controller (PLC), monitor pressure and temperature in real-time. This automation ensures the melt remains stable and safe, activating emergency shutdown mechanisms if parameters drift beyond set limits.

Critical Industry Applications

Aerospace and Power Generation

The aerospace industry relies on VIM to produce superalloys and titanium alloys for aircraft engines, missiles, and satellites. These components must withstand extreme heat and stress without failing.

Similarly, the power generation sector uses VIM-produced materials for gas turbine components and nuclear reactor parts. The high homogeneity of the melt ensures these parts perform reliably over long service lives.

Electronics and Semiconductors

In the electronics sector, purity is paramount. VIM furnaces produce the high-purity materials required for semiconductors, transistors, and microchips.

Even microscopic impurities can cause failure in electronic components. The vacuum environment ensures the base materials are free from contaminants that could disrupt electrical conductivity or performance.

Medical and Nuclear Sectors

The medical industry utilizes VIM to manufacture surgical instruments and implants. The ultra-clean surfaces and lack of inclusions are vital for biocompatibility and durability in the human body.

The nuclear industry also employs this technology for processing low-enriched uranium into fuel rods, leveraging the furnace's ability to safely handle hazardous materials under controlled conditions.

Understanding the Operational Trade-offs

System Complexity and Support

While VIM furnaces are designed for ease of operation with intuitive controls, they are complex systems consisting of multiple critical subsystems. Reliable operation requires functioning cooling systems, gas flow controls (for argon or helium), and vacuum pumps.

Specificity of Application

This technology is specialized for high-value, high-purity applications. While it offers versatile material compatibility—ranging from ceramics to stainless steel—it is an advanced manufacturing solution intended for scenarios where material quality cannot be compromised. It is less relevant for producing low-grade metals where atmospheric contamination is acceptable.

Making the Right Choice for Your Goal

To determine if VIM technology aligns with your production needs, consider the specific demands of your end product.

- If your primary focus is Structural Integrity (Aerospace/Power): You require VIM to eliminate oxide inclusions that act as crack initiation sites in superalloys and turbine blades.

- If your primary focus is Electronic Performance (Semiconductors): You require VIM to achieve the ultra-high purity levels necessary to prevent signal interference and ensure consistent conductivity.

Ultimately, the Vacuum Induction Melting furnace is the definitive tool for converting raw metals into the advanced, defect-free materials that power modern technology.

Summary Table:

| Feature | VIM Technology Benefit | Industry Impact |

|---|---|---|

| Atmospheric Control | High-vacuum environment | Eliminates oxygen, nitrogen, and hydrogen impurities |

| Heating Method | Electromagnetic Induction | Precise temperature control and chemical homogeneity |

| Material Integrity | Prevents oxidation | Preserves reactive elements for aerospace superalloys |

| Product Quality | Inclusion-free melt | Ensures structural reliability and atomic-level purity |

| Process Control | PLC-managed automation | Consistent, repeatable results for mission-critical parts |

Elevate Your Material Standards with KINTEK

Precision in melting is the foundation of innovation in aerospace, electronics, and medical manufacturing. At KINTEK, we understand that even microscopic impurities can compromise the integrity of your advanced materials.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-performance Vacuum Induction Melting furnaces—all customizable to meet your unique laboratory or industrial needs.

Ready to achieve ultra-clean results and exact chemical precision? Contact our technical experts today to find the perfect thermal processing solution for your high-purity applications.

Visual Guide

References

- Salokhiddin Absattarov, Jamshed Avliyokulov. Dependence establishment of mass transfer coefficient in third kind boundary condition on temperature during vacuum carburizing of steels. DOI: 10.1063/5.0266787

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Where is the target material placed in an induction heater and what happens to it? Discover the Science of Non-Contact Heating

- What solutions are implemented for vacuum induction melting (VIM)? Achieve Superior Alloy Purity and Performance

- What is the role of the power supply in an IGBT-based induction heater circuit? Unlock Maximum Heating Performance

- How does an induction furnace improve the purity of melted gold? Achieve Maximum Purity and Yield

- What is the function of a vacuum induction furnace with cold copper crucible in Ti-5Al-2.5Sn alloy preparation?

- What are the primary advantages of using a Vacuum Induction Cold Crucible Furnace (VCCF)? Achieve Extreme Steel Purity

- What are the benefits of induction furnace? Achieve Unmatched Efficiency & Purity in Metal Melting

- How do induction furnaces contribute to sustainability in metal casting? Boost Efficiency and Cut Waste