Vacuum Induction Melting (VIM) is a highly controlled metallurgical process executed through a suite of integrated solutions. The core components include high-efficiency copper induction coils for generating precise electromagnetic fields, tilt-pour mechanisms for controlled casting, and advanced secondary systems like mold pre-heating to ensure casting integrity. These solutions work in concert within a vacuum to produce alloys with superior purity and structural quality.

The specific technical solutions implemented in VIM are not arbitrary; they are a direct answer to the fundamental challenge of producing ultra-pure, chemically precise superalloys and reactive metals that cannot be made in a standard atmospheric environment.

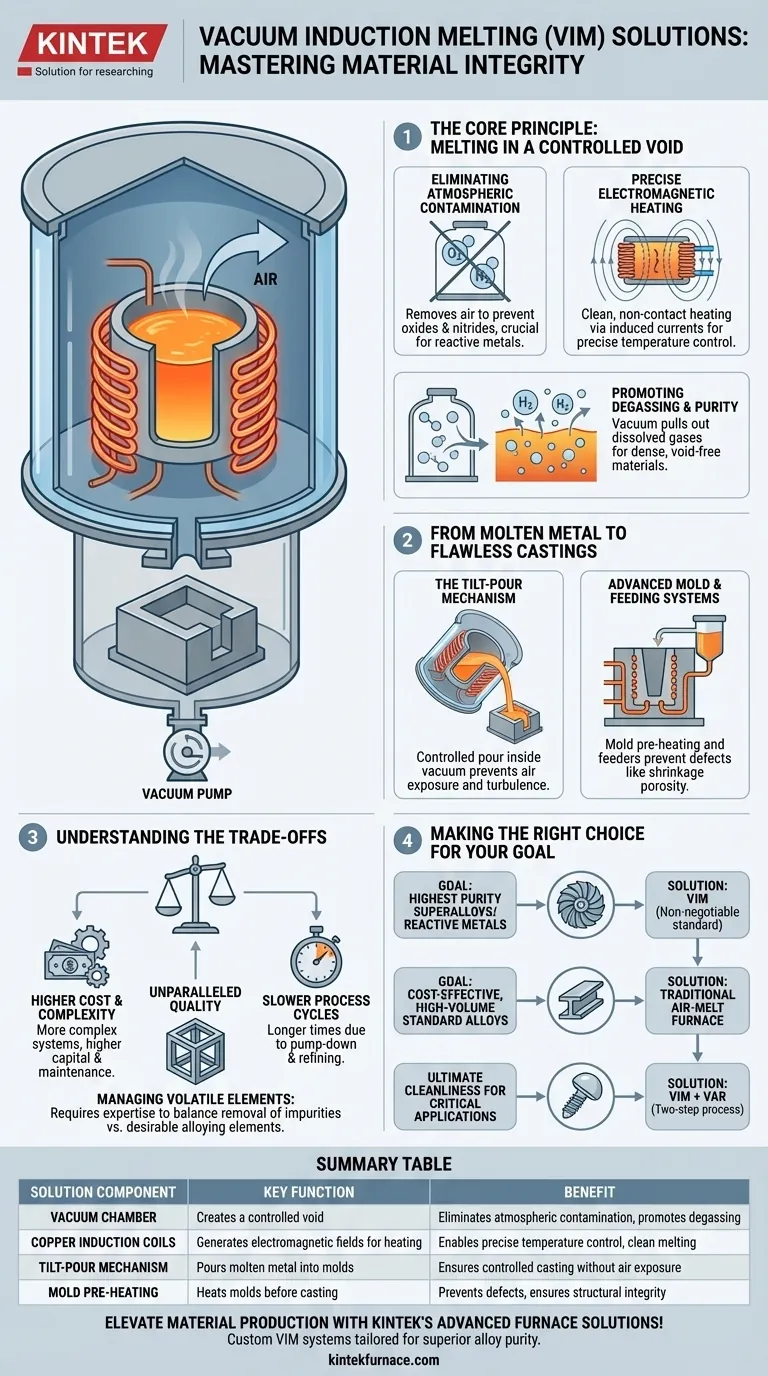

The Core Principle: Melting in a Controlled Void

The defining feature of VIM is its vacuum chamber, which fundamentally changes the melting environment. This controlled void is the reason VIM can achieve results impossible with other methods.

Eliminating Atmospheric Contamination

In a traditional furnace, molten metal reacts aggressively with oxygen and nitrogen in the air, forming impurities (oxides and nitrides) that degrade the final material's properties.

The VIM process begins by pumping the air out of a sealed chamber, eliminating this primary source of contamination. This is critical for reactive materials like titanium or superalloys containing aluminum.

Precise Electromagnetic Heating

At the heart of the system are water-cooled copper induction coils. These coils do not generate heat directly. Instead, they create a powerful, alternating electromagnetic field.

This field induces strong electrical currents within the metallic charge material itself, causing it to heat and melt rapidly from the inside out. This method is exceptionally clean, as the heat source never touches the metal, and allows for extremely precise temperature control.

Promoting Degassing and Purity

The vacuum environment does more than just prevent contamination; it actively purifies the melt.

Dissolved gases, particularly hydrogen, and unwanted volatile trace elements within the molten metal are effectively pulled out by the vacuum. This degassing step is essential for creating dense, void-free materials with predictable mechanical performance.

From Molten Metal to Flawless Castings

Achieving a pure, molten bath is only half the battle. The VIM solutions for casting are designed to preserve that purity all the way to the final solidified part.

The Tilt-Pour Mechanism

Once the metal reaches the correct temperature and chemical composition, the entire crucible assembly is tilted mechanically to pour the molten metal into a waiting mold.

Crucially, this entire transfer happens inside the vacuum chamber. This prevents the metal from being exposed to air during the pour, which would negate the benefits of vacuum melting. The controlled pour also minimizes turbulence, reducing the risk of defects.

Advanced Mold and Feeding Systems

To prevent casting defects like shrinkage porosity, VIM systems often incorporate mold pre-heating and secondary feeding systems.

Pre-heating the mold ensures a more controlled solidification gradient, while secondary feeders provide a reservoir of molten metal to compensate for volume reduction as the casting cools and solidifies. This guarantees a dense, structurally sound final product.

Understanding the Trade-offs

While VIM offers unparalleled quality, it is a specialized process with inherent trade-offs that make it unsuitable for every application.

Higher Initial Cost and Complexity

VIM furnaces are significantly more complex than their air-melt counterparts. The need for robust vacuum chambers, high-capacity pumping systems, and sophisticated controls leads to higher capital investment and maintenance costs.

Slower Process Cycle Times

Achieving a deep vacuum is a time-consuming step. The overall cycle time—including pump-down, melting, refining, and cooling—is considerably longer than for a simple air melt. This impacts overall production throughput.

Managing Volatile Alloying Elements

The same vacuum that removes unwanted volatile impurities can also remove desirable, high-vapor-pressure alloying elements (like manganese or chromium) if the process is not carefully controlled. Operating a VIM furnace requires significant metallurgical expertise to manage this delicate balance.

Making the Right Choice for Your Goal

The decision to use VIM depends entirely on the performance requirements of the final material.

- If your primary focus is producing the highest purity superalloys or reactive metals: VIM is the non-negotiable standard, as its vacuum environment is essential to prevent contamination and control chemistry.

- If your primary focus is cost-effective, high-volume production of standard steel or aluminum alloys: A traditional air-melt induction or arc furnace is often the more practical and economical choice.

- If your primary focus is achieving the ultimate material cleanliness for critical applications: Consider a two-step process like VIM followed by Vacuum Arc Remelting (VAR), where VIM is used to create a pure electrode for a secondary refining process.

Ultimately, VIM solutions are a strategic investment in material integrity, enabling the creation of alloys that meet the world's most demanding performance requirements.

Summary Table:

| Solution Component | Key Function | Benefit |

|---|---|---|

| Vacuum Chamber | Creates a controlled void | Eliminates atmospheric contamination and promotes degassing |

| Copper Induction Coils | Generates electromagnetic fields for heating | Enables precise temperature control and clean melting |

| Tilt-Pour Mechanism | Pours molten metal into molds | Ensures controlled casting without air exposure |

| Mold Pre-Heating | Heats molds before casting | Prevents defects and ensures structural integrity |

Elevate your material production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored VIM systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior alloy purity and performance. Contact us today to discuss how we can optimize your vacuum induction melting processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity