Vacuum Furnace

Vacuum Induction Melting Furnace and Arc Melting Furnace

Item Number : KT-VI

Price varies based on specs and customizations

- Max temperature

- 2000 ℃

- Crucible effective capacity (Steel)

- 20kgs

- Max melting vacuum

- 7×10-3Pa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

Discover KINTEK's Advanced Vacuum Induction Melting Furnace

KINTEK's Vacuum Induction Melting Furnace is engineered for superior performance in melting metals and alloys under precisely controlled vacuum or inert gas conditions. Leveraging our exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial clients with advanced high-temperature furnace solutions. This specialized furnace, capable of reaching temperatures up to 2000℃, is crucial for applications demanding high purity, such as casting aircraft components and refining high-purity metals.

Our comprehensive product line extends beyond this model to include Muffle Furnaces, Tube Furnaces, Rotary Furnaces, other specialized Vacuum & Atmosphere Furnaces, and sophisticated CVD/PECVD/MPCVD Systems. What truly sets KINTEK apart is our strong deep customization capability, allowing us to precisely tailor solutions to meet your unique experimental or production requirements.

Explore the detailed features and specifications below. If you're ready to enhance your material processing capabilities or have specific needs, please contact us to discuss your project.

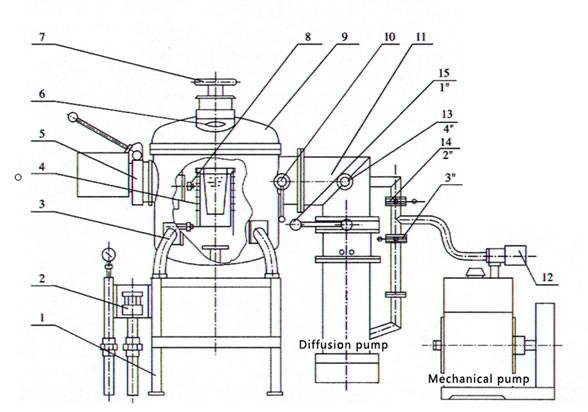

Detail & Parts

Furnace Structure(1. Base 2. Water cooling system 3. Furnace stack 4. Inductor 5.Sealing rotary bearing 6.Observation window 7.Feeder 8.Electrode 9. stove lids 10.Temperature Measuring 11.Vacuum system 12.Inflatable vacuum solenoid valve 13.vent valve 14.Φ50 Vacuum valve 15.Φ300)

Product Overview and Key Features

The Vacuum Induction Melting Furnace is specialized equipment designed for melting and casting metals under vacuum or inert gas conditions. It utilizes a water-cooled induction coil and refractory lining, crucial for processes requiring high purity and precise temperature control, operating at temperatures up to 2000℃. This furnace is particularly beneficial for melting valuable active metals and alloys, preventing reactions with non-metallic inclusions, and removing harmful dissolved gases and pollutants from the molten metals. Key features include:

- Air-Tight Water-Cooled Steel Jacket: The furnace is equipped with an air-tight, water-cooled steel jacket that can withstand the required vacuum for processing, ensuring a stable and controlled environment for melting.

- Induction Heating System: Utilizing medium frequency induction heating, the furnace can reach temperatures up to 2000℃, making it suitable for melting a wide range of metals and alloys, including nickel, special steel, and high-temperature alloys.

- Crucible and Refractory Lining: The metal is melted in a crucible housed in a water-cooled induction coil, and the furnace is lined with suitable refractories to enhance durability and performance.

- Vacuum and Inert Gas Casting: The molten metal can be poured or cast under either vacuum or inert gas environments, providing flexibility in processing and ensuring the purity of the final product.

- Advanced Features: Depending on the size and model, the furnace may include tilt and pour mechanisms, casting chambers, sampling ports, and mould handling facilities with vacuum interlock systems, enhancing automation and precision in the melting process.

These features collectively ensure high-quality melting and casting of metals, making the Vacuum Induction Melting Furnace an indispensable tool for industries requiring precision and purity in their metalworking processes.

Applications

The Vacuum Induction Melting Furnace is a specialized equipment used for melting and casting metals under vacuum conditions, primarily utilizing medium-frequency induction heating. This technology is crucial in various high-tech industries due to its ability to produce high-purity metals and alloys with precise control over the melting environment. Key applications include:

- Aerospace components casting

- Manufacturing of complex valves for extreme conditions

- Refining high-purity metals and alloys

- Production of electrodes for remelting

- Nickel and special steel production

- Precision alloy fabrication

- Active metal processing

- High-temperature alloy development

- Magnet material creation

Operating Principle

The vacuum induction melting furnace operates on the principle of medium frequency induction heating, where a high vacuum environment is created to melt metals. The furnace utilizes an induction coil to generate an alternating electromagnetic field, which induces eddy currents within the metal, causing it to heat up and melt. The vacuum environment prevents oxidation and contamination of the molten metal, allowing for the production of high-purity alloys. This process is particularly suitable for melting high-temperature alloys, active metals, and materials requiring precise composition control.

Key System Components & Design Features

Our Vacuum Induction Melting Furnace incorporates thoughtfully designed components to ensure reliability, efficiency, and ease of use:

- Furnace Body: The furnace body and furnace cover have a water-cooled interlayer to ensure the furnace surface temperature will not be too high. An optional side door on the furnace body can be added according to user requirements. The furnace cover is equipped with an alloy feeder and observation window, which allows for the addition of different alloy raw materials during smelting and observation of the working conditions in the furnace.

- Inductor: The furnace inductor is coiled into a spiral coil with thick-wall copper tubes. The outer layer of the induction coil is covered with a ceramic coating, which increases the firmness and extends the service life of the coil while ensuring its insulation.

- Furnace Tilting Mechanism: Manual, electric, and hydraulic furnace tilting options are available. The furnace tilting angle is designed to tilt forward 105 degrees and backward 10 degrees, ensuring no residual liquid. The furnace tilting speed can be adjusted continuously.

- Vacuum System: Consists of a mechanical pump, Roots pump, diffusion pump or booster diffusion pump, vacuum valves, damping elastic sleeves, and vacuum pipelines. The configuration of the vacuum system is tailored to the physical and chemical properties and process of the smelting materials.

- Medium Frequency Power Supply: Utilizes an IGBT medium frequency power unit, enabling maximum temperatures up to 2000℃.

- Electrical Control System: Features a Touch screen controller with PLC, vacuum measuring instrument, temperature measuring instrument, and operation buttons, indicator lights, and other components. It enables the operation and control of the pneumatic system, vacuum system, furnace cover lifting, furnace tilting, etc.

Key Benefits & Process Advantages

Utilizing the KINTEK Vacuum Induction Melting Furnace offers significant advantages for your material processing:

- Effectively control and adjust alloy composition to produce high-performance metal or alloy materials.

- Capable of inhibiting the formation of non-metallic oxide inclusions produced in the metal solution and casting high-quality castings.

- The unique electromagnetic stirring feature can effectively avoid element segregation during alloy smelting.

- According to the different melting points of elements, some harmful volatile trace elements, such as antimony, tellurium, selenium, bismuth, etc., can be purposely removed.

Technical specifications

| Crucible effective volume | 4L |

|---|---|

| Crucible effective capacity (Steel) | 20kgs |

| Max temperature | 2000 ℃ |

| Max melting vacuum |

|

| Rated power | 60KW |

| Rated voltage | 375V |

| Power frequency | 50HZ |

| Rated frequency | 1500~2500HZ |

| Heat element | Induction copper coil |

| Vacuum system |

|

| Model | Capacity | Temperature | Vacuum | Rated power |

|---|---|---|---|---|

| KT-VI5 | 5kg | 1700 ℃ | 6x10-3Pa | 40Kw |

| KT-VI10 | 10kg | 40Kw | ||

| KT-VI25 | 25kg | 75Kw | ||

| KT-VI50 | 50kg | 100Kw | ||

| KT-VI100 | 100kg | 160Kw | ||

| KT-VI200 | 200kg | 200Kw | ||

| KT-VI500 | 500kg | 500Kw | ||

| Semi-continuously melting production can be customized | ||||

Partner with KINTEK for Your High-Temperature Furnace Needs

KINTEK's Vacuum Induction Melting Furnaces offer unparalleled precision and purity for your demanding applications. With our expertise in high-temperature technology and commitment to customization, we can provide the perfect solution for your laboratory or production needs.

Don't see the exact specifications you need? Our team excels at deep customization. Contact us today to discuss your unique requirements, request a quote, or learn more about how our furnaces can benefit your work.

FAQ

What Are The Main Applications Of A Vacuum Furnace?

What Is A Vacuum Induction Furnace?

What Is A Dental Furnace Used For?

What Is An Atmosphere Furnace Used For?

What Are The Main Applications Of A Muffle Furnace?

What Are The Key Features Of A Vacuum Furnace?

What Are The Main Applications Of Vacuum Induction Furnaces?

What Are The Key Features Of A Dental Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Key Features Of A Muffle Furnace?

How Does A Vacuum Furnace Work?

How Does A Vacuum Induction Furnace Work?

How Does A Dental Furnace Work?

How Does An Atmosphere Furnace Work?

How Does A Muffle Furnace Work?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using A Vacuum Induction Furnace?

What Are The Advantages Of Using A Dental Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Are The Advantages Of Using A Muffle Furnace?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Vacuum Induction Furnaces Are Available?

What Safety Features Should A Dental Furnace Have?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Types Of Muffle Furnaces Are Available?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

Why Is Temperature Control Important In Vacuum Induction Furnaces?

What Types Of Dental Furnaces Are Available?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Can Vacuum Furnaces Be Customized For Specific Applications?

What Materials Can Be Processed In A Vacuum Induction Furnace?

How Does The Vacuum Environment Benefit Material Processing?

4.9

out of

5

Incredible precision and speed! The furnace melts metals flawlessly, a game-changer for our lab.

4.8

out of

5

Top-notch quality and durability. Worth every penny for our research needs.

4.7

out of

5

Fast delivery and easy setup. The furnace outperforms competitors effortlessly.

4.9

out of

5

Cutting-edge technology with consistent results. Highly recommended for serious metallurgists.

4.8

out of

5

Exceptional value for money. The furnace handles high temperatures like a champ.

4.9

out of

5

Unmatched efficiency and reliability. Our production has never been smoother.

4.7

out of

5

Superior build quality and advanced features. A must-have for any modern foundry.

4.8

out of

5

Impressive performance and minimal maintenance. Exceeded all our expectations.

4.9

out of

5

The furnace arrived ahead of schedule and works like a dream. Perfect for precision melting.

4.8

out of

5

Innovative design and robust construction. A stellar addition to our workshop.

4.7

out of

5

Consistent results and user-friendly controls. Makes complex tasks seem simple.

4.9

out of

5

The furnace’s speed and accuracy are unparalleled. A true industry leader.

4.8

out of

5

Durable and efficient. It’s transformed our metalworking process entirely.

4.9

out of

5

Advanced technology meets reliability. Perfect for high-precision applications.

4.7

out of

5

Quick delivery and flawless operation. The furnace is a joy to work with.

4.8

out of

5

Superior craftsmanship and innovative features. A standout in its category.

4.9

out of

5

The furnace’s performance is stellar. It’s revolutionized our production line.

4.7

out of

5

Reliable and efficient. The perfect tool for demanding metallurgical work.

4.8

out of

5

Exceptional build and advanced tech. It’s a powerhouse in a compact design.

4.9

out of

5

The furnace delivers perfection every time. A brilliant investment for any lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!