The primary benefits of an induction furnace are its exceptional energy efficiency, precise process control, and the high purity of the metal it produces. Unlike traditional fuel-fired furnaces that heat the environment around the metal, an induction furnace uses an electromagnetic field to heat the metal directly. This fundamental difference results in a cleaner, faster, and more cost-effective melting process.

The core advantage of induction technology lies in its direct, contactless heating method. This fundamental difference from traditional furnaces leads to superior energy efficiency, precise process control, and a cleaner melt, ultimately resulting in lower operational costs and higher-quality final products.

The Foundation: How Direct Heating Drives Efficiency

The efficiency of an induction furnace stems from its unique method of energy transfer. By generating heat directly within the metallic charge, it avoids the massive energy losses inherent in combustion-based systems.

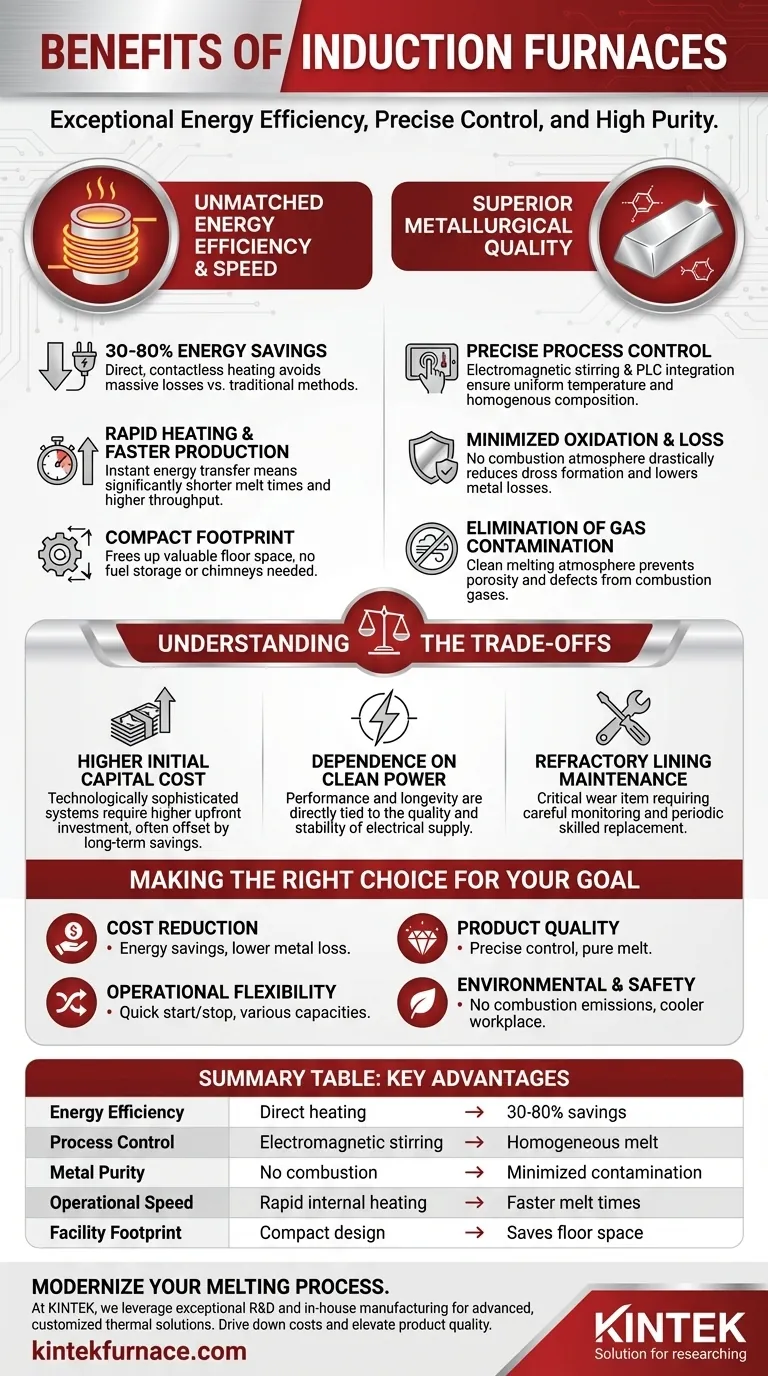

Unmatched Energy Efficiency

Induction furnaces can deliver energy savings of 30–80% compared to traditional methods. Because heat is generated inside the metal itself, very little energy is wasted heating the furnace walls or surrounding air.

Furthermore, there is zero standby heat loss, as power is consumed only when the melting cycle is active.

Rapid Heating and Production Speed

Energy is transferred to the metal almost instantly, resulting in significantly faster heating speeds and shorter melt times. This directly translates to higher production efficiency and throughput for your operation.

Compact Footprint

Induction melting systems are remarkably compact. They do not require space for fuel storage, chimneys, or complex exhaust handling systems, which frees up valuable floor space and can reduce overall operational facility costs.

Achieving Superior Metallurgical Quality

Direct heating provides a level of control that is simply unattainable with fuel-fired furnaces. This control is the key to producing metal of a consistently higher quality.

Precise Temperature and Composition Control

The electromagnetic field naturally stirs the molten bath, creating a highly uniform temperature and a homogenous chemical composition throughout the melt.

Modern furnaces integrated with PLCs (Programmable Logic Controllers) allow for precise, repeatable control over the entire process, enabling operators to program specific melt recipes for different alloys.

Minimized Oxidation and Metal Loss

Because there is no combustion, there are no oxygen-rich byproducts to react with the molten metal. This drastically reduces oxidation and dross formation, leading to lower metal losses and a higher yield from your raw materials.

Elimination of Gas Contamination

Fuel-fired furnaces introduce gases like hydrogen and carbon from the combustion process, which can dissolve into the metal and cause defects like porosity. Induction melting occurs in a clean atmosphere, eliminating this source of gas contamination.

Understanding the Trade-offs

While the benefits are substantial, an objective evaluation requires acknowledging the considerations and potential challenges associated with induction technology.

Higher Initial Capital Cost

Induction furnace systems are technologically sophisticated and often require a higher upfront investment compared to simpler, traditional furnace types. However, this cost is frequently offset by long-term operational savings.

Dependence on Clean Power

The furnace's performance and efficiency are directly tied to the quality and stability of your electrical supply. Power sags, surges, or harmonics can potentially impact furnace operation and component longevity.

Refractory Lining Maintenance

The refractory lining that contains the molten metal is a critical wear item. Its condition must be carefully monitored, and it requires periodic replacement by skilled personnel, which represents a significant ongoing operational cost.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on your operational priorities. Induction furnaces offer a compelling case across several key business objectives.

- If your primary focus is cost reduction: The significant energy savings, lower metal loss, and elimination of fuel costs offer a clear path to lower long-term operational expenses.

- If your primary focus is product quality: The precise temperature control, homogenous melt, and clean atmosphere ensure superior metallurgical purity and consistency in every batch.

- If your primary focus is operational flexibility: The ability to quickly start, stop, and melt various metals and alloys in capacities from kilograms to tons makes induction a highly adaptable solution.

- If your primary focus is environmental and worker safety: The elimination of combustion emissions and a cooler, quieter workplace make it the superior choice for meeting modern EHS standards.

Ultimately, adopting induction furnace technology is a strategic decision to modernize your melting process for greater efficiency, control, and quality.

Summary Table:

| Benefit | Key Advantage | Impact |

|---|---|---|

| Energy Efficiency | Direct, contactless heating | 30-80% energy savings vs. traditional methods |

| Process Control | Electromagnetic stirring & PLC integration | Homogeneous melt & precise temperature control |

| Metal Purity | No combustion atmosphere | Minimized oxidation & elimination of gas contamination |

| Operational Speed | Rapid, internal heating | Faster melt times & higher production throughput |

| Facility Footprint | Compact design, no fuel systems | Saves valuable floor space & reduces facility costs |

Ready to modernize your melting process with the efficiency and precision of an induction furnace?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions for diverse laboratories and production facilities. Our deep customization capabilities ensure your induction furnace system is precisely tailored to meet your unique operational requirements for metal purity, energy savings, and process control.

Contact our experts today to discuss how a KINTEK induction furnace can drive down your costs and elevate your product quality.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys