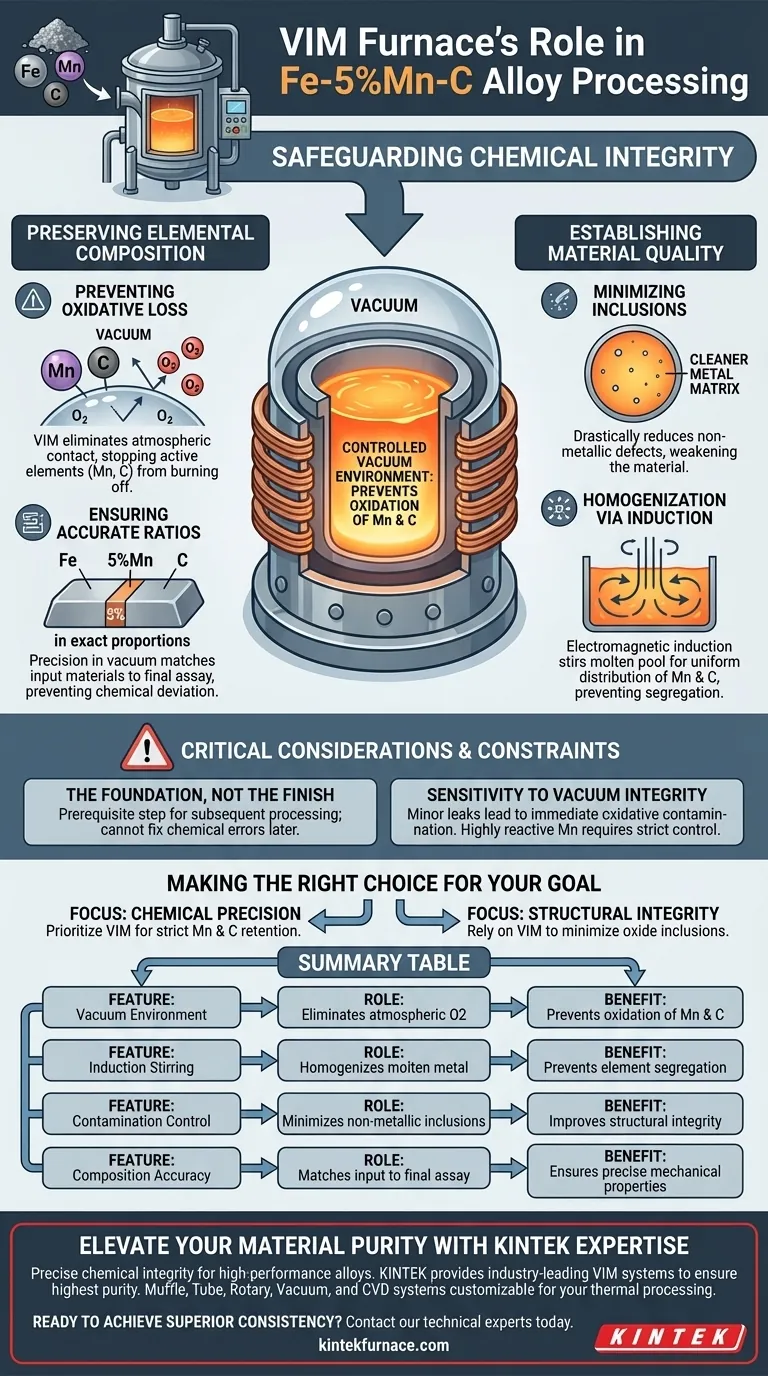

The primary role of a vacuum induction melting (VIM) furnace in processing Fe-5%Mn-C alloys is to safeguard the material's chemical integrity during the transition from raw material to liquid metal. It provides a controlled vacuum environment that specifically prevents the oxidation of active elements—manganese (Mn) and carbon (C)—ensuring the alloy achieves a high-purity composition and a precise elemental ratio.

The VIM furnace serves as the foundational quality control step; it eliminates atmospheric contamination to prevent the loss of reactive alloying elements and minimizes non-metallic inclusions, creating the necessary purity for high-performance applications.

Preserving Elemental Composition

Preventing Oxidative Loss

Manganese (Mn) and Carbon (C) are classified as active elements. When exposed to high temperatures in a standard atmosphere, they react rapidly with oxygen. The VIM furnace eliminates this risk by operating in a vacuum, ensuring these critical elements remain part of the alloy rather than burning off as oxides.

Ensuring Accurate Ratios

To achieve the specific "Fe-5%Mn-C" formulation, the ratio of iron to manganese and carbon must be exact. By preventing oxidative loss, the furnace ensures that the amount of raw material added matches the final composition of the ingot. This precision prevents chemical deviation that would otherwise alter the alloy's intended mechanical properties.

Establishing Material Quality

Minimizing Non-Metallic Inclusions

When active elements oxidize, they often form "inclusions"—microscopic particles of dirt or slag trapped inside the metal. These inclusions weaken the final material. The vacuum environment drastically reduces the production of these non-metallic defects, resulting in a cleaner, higher-purity metal matrix.

Homogenization via Induction

While the primary goal for this alloy is oxidation prevention, the VIM process also utilizes electromagnetic induction. This mechanism naturally stirs the molten pool. This stirring effect ensures that the manganese and carbon are uniformly distributed throughout the iron, preventing segregation and ensuring the alloy is consistent from edge to center.

Critical Considerations and Constraints

The Foundation, Not the Finish

It is vital to recognize that the VIM furnace establishes the material foundation, not the final product. It produces a high-purity ingot or casting. This step is a prerequisite for subsequent processing (such as rolling or heat treatment) to create high-performance alloy plates. If the initial melting is compromised, no amount of downstream processing can fix the chemical errors.

Sensitivity to Vacuum Integrity

The process is entirely dependent on the maintenance of a high-vacuum environment. Because Manganese is highly reactive, even minor leaks or insufficient vacuum levels will lead to immediate oxidative contamination. The "controlled" aspect of the environment is non-negotiable for this specific alloy chemistry.

Making the Right Choice for Your Goal

- If your primary focus is Chemical Precision: Prioritize VIM to strictly prevent the "burn-off" of Manganese and Carbon, ensuring your final assay matches your input calculations.

- If your primary focus is Structural Integrity: Rely on VIM to minimize non-metallic oxide inclusions, which act as crack initiation sites in high-performance plates.

The vacuum induction melting furnace transforms a mixture of reactive ingredients into a chemically stable, high-purity unified alloy.

Summary Table:

| Feature | Role in Fe-5%Mn-C Processing | Primary Benefit |

|---|---|---|

| Vacuum Environment | Eliminates atmospheric oxygen | Prevents oxidation of Mn and C |

| Induction Stirring | Homogenizes molten metal | Prevents element segregation |

| Contamination Control | Minimizes non-metallic inclusions | Improves structural integrity |

| Composition Accuracy | Matches input to final assay | Ensures precise mechanical properties |

Elevate Your Material Purity with KINTEK Expertise

Precise chemical integrity is the foundation of high-performance Fe-5%Mn-C alloys. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to eliminate oxidative loss and ensure the highest purity for your laboratory and production needs.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique thermal processing requirements. Whether you are developing advanced alloys or performing critical heat treatments, our equipment delivers the precision your research demands.

Ready to achieve superior alloy consistency? Contact our technical experts today to discuss your custom furnace solution.

Visual Guide

References

- Change in Dislocation Density via Ausforming in Fe-5%Mn-C Alloy with Lath Martensitic Structure. DOI: 10.2355/isijinternational.isijint-2025-090

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What materials can induction furnaces melt? A Guide to Metals and Alloys

- What is the primary role of a vacuum induction furnace in the initial preparation of Fe–32Ni alloys?

- What is the objective of using a high-power induction heating system? Optimize High-Entropy Alloy Melting

- How do IGBT induction melting furnaces compare to traditional melting systems? A Generational Leap in Melting Technology

- What role does a vacuum induction furnace play in removing phosphorus impurities from silicon? Advanced Vapor Refining

- What auxiliary role does a Ni/Al2O3 catalyst play in induction heating? Enhancing Ammonia Decomposition Uniformity

- What are the main industrial applications of induction heating? Unlock Precision and Efficiency in Your Processes

- What is the role of a Vacuum Induction Melting (VIM) furnace in Cobalt-Rhenium alloy production? Ensure Pure Alloys