The primary objective of using a high-power induction heating system for multi-stage melting is to manage the extreme thermal disparities between different elements in a high-entropy alloy. By utilizing high energy input to prepare intermediate alloys, the system exploits a dissolution mechanism that lowers the overall processing temperature, ensuring that refractory elements melt fully without causing volatile elements to evaporate.

Core Takeaway High-entropy alloys often combine elements with conflicting melting points and volatilities. A multi-stage induction strategy uses low-melting-point phases to dissolve high-melting-point elements, effectively lowering the thermal barrier of the process and preserving the precise chemical composition of the final ingot.

The Mechanics of Multi-Stage Melting

Overcoming Melting Point Disparities

High-entropy alloys (HEAs) frequently consist of elements with vastly different melting points. Trying to melt these simultaneously in a single batch often leads to complications.

A high-power induction system provides the necessary energy to first prepare intermediate alloys. These usually consist of the high-melting-point elements.

The Dissolution Mechanism

The core principle of this strategy is using liquid phases as a solvent.

Once the intermediate alloys are formed, other elements are added gradually. The system utilizes a mechanism where low-melting-point phases effectively "dissolve" the high-melting-point refractory elements.

This is distinct from simply applying enough heat to melt the most refractory element in isolation. It relies on chemical interaction to facilitate the phase change.

Lowering the Thermal Barrier

By relying on dissolution rather than brute-force heating, the overall melting temperature of the batch is significantly reduced.

This means the system does not need to maintain the peak temperature required to melt the most heat-resistant element in the mix for the entire duration of the process.

Preserving Compositional Integrity

Mitigating Evaporation Loss

One of the greatest risks in HEA preparation is the loss of volatile elements, such as chromium.

If the system were to heat the entire mixture to the melting point of the most refractory element, these volatile components would likely evaporate.

By lowering the overall processing temperature through multi-stage dissolution, the system suppresses this evaporation. This ensures the final alloy retains its intended compositional ratio.

Electromagnetic Stirring

While the primary goal is thermal management, the induction system offers a secondary benefit of intense electromagnetic stirring.

This forces the molten metal to move continuously, ensuring that the intermediate alloys and added elements mix into a highly uniform composition.

Understanding the Trade-offs

Process Complexity

Multi-stage melting is inherently more complex than single-step processing.

It requires precise timing and a calculated order of element addition. Errors in the sequencing of intermediate alloys can lead to incomplete melting or segregation.

Crucible Contamination Risks

High-power induction heating involves intense energy transfer. In standard setups, this can lead to interactions between the molten metal and the crucible.

However, advanced variations, such as vacuum magnetic levitation, can mitigate this by suspending the metal. Without such levitation features, the high power required for refractory elements increases the risk of crucible material contaminating the alloy.

Making the Right Choice for Your Goal

The use of high-power induction for multi-stage melting is a strategic choice for complex alloy systems.

- If your primary focus is compositional accuracy: Use this multi-stage approach to prevent the evaporation of volatile elements like chromium.

- If your primary focus is homogeneity: Rely on the dissolution mechanism and electromagnetic stirring to ensure refractory elements are fully integrated into the matrix.

Summary: By treating the melting process as a staged chemical dissolution rather than a simple thermal event, you can produce high-quality alloys that are both chemically accurate and structurally uniform.

Summary Table:

| Feature | Multi-Stage Induction Objective | Technical Benefit |

|---|---|---|

| Thermal Management | Manages extreme melting point disparities | Lower overall processing temperatures |

| Phase Control | Uses liquid phases as a solvent | Dissolves refractory elements without brute heat |

| Compositional Integrity | Mitigates evaporation of volatile elements | Preserves precise chemical ratios (e.g., Chromium) |

| Homogeneity | Intense electromagnetic stirring | Ensures uniform distribution of elements |

Elevate Your Material Research with KINTEK

Precision in high-entropy alloy preparation requires more than just heat—it requires specialized control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Induction, Vacuum, CVD, and Muffle systems designed to handle the most demanding metallurgical workflows. Whether you need a customizable solution for multi-stage melting or a high-temp furnace for refractory materials, our equipment ensures compositional integrity and structural uniformity for your lab.

Ready to optimize your alloying process? Contact KINTEK today for a customized solution!

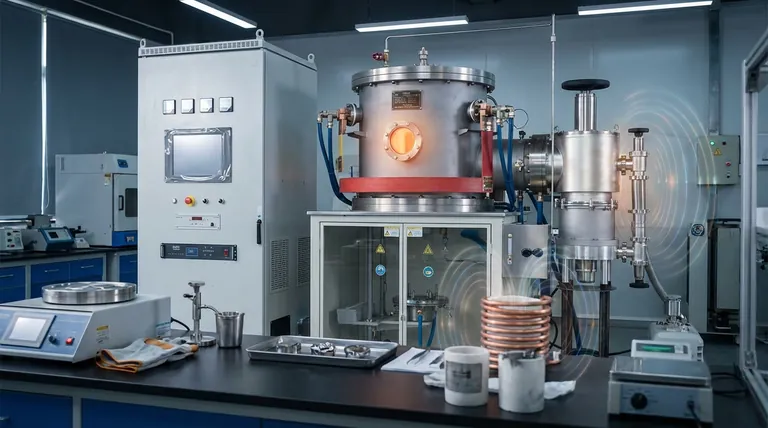

Visual Guide

References

- Laurent Peltier, Jérome Slowensky. Design of Multiphase Compositionally Complex Alloys for Enhanced Hardness at Elevated Temperatures and Machinability: Comparative Study with Inconel 718. DOI: 10.1002/adem.202501146

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is high-purity argon gas purging necessary during the melting of high-entropy alloys? Ensure Alloy Integrity

- What industries commonly use vacuum or protective atmosphere induction furnaces? Essential for Aerospace, Medical, and More

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- How are induction furnaces used in investment casting? Achieve Precision Melting for High-Quality Cast Parts

- What factors influence induction heater circuit design? Optimize Power, Frequency, and Material for Efficiency

- Why is maintaining a low-pressure vacuum environment necessary during induction heating graphitization?

- Why is a vacuum induction furnace necessary for Seebeck coefficient measurement? Achieve Precise Thermal Data

- What is the coreless induction furnace used for in the metal thermal processing industry? Achieve Clean, Efficient Metal Melting