In essence, a coreless induction furnace is a high-powered electric furnace used to melt metals. Its primary function in the metal processing industry is to take solid metal charges, such as scrap, ingots, or recycled material, and efficiently heat them into a liquid state for casting, alloying, or holding. The technology operates without a central iron core, allowing for rapid melting and excellent metallurgical control.

A coreless induction furnace is not just a heater; it is a versatile tool for melting and refining. Its key value lies in its ability to provide clean, efficient, and highly controlled melting for a vast range of metals, making it indispensable for modern foundries and metallurgical operations.

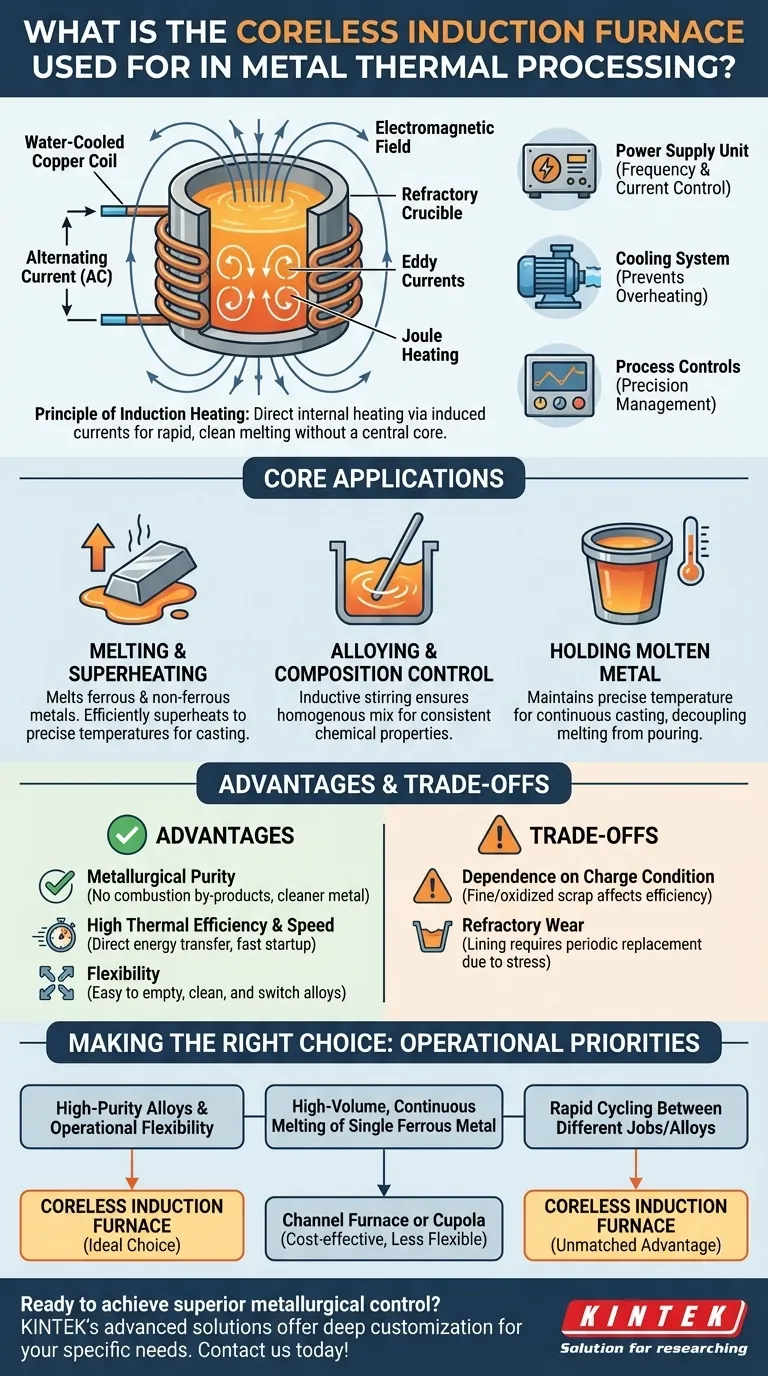

How a Coreless Induction Furnace Works

To understand its applications, you must first grasp its fundamental operating principle. The furnace does not use external heating elements or combustion.

The Principle of Induction Heating

The furnace is built around a refractory-lined vessel, or crucible, which holds the metal charge. This crucible is encircled by a water-cooled copper coil.

When a powerful alternating current (AC) flows through this coil, it generates a strong, rapidly changing electromagnetic field inside the crucible.

This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal charge itself. The metal's natural electrical resistance causes it to heat up rapidly due to the flow of these eddy currents, a principle known as Joule heating. This internal heating continues until the metal melts.

Key Components and Their Roles

A complete system relies on several integrated parts. The power supply unit converts mains electricity into the specific frequency and high current required for the coil. A cooling system, typically using water, is critical to prevent the copper coil from overheating and melting. Finally, modern process controls allow operators to precisely manage power input, temperature, and melting time.

Core Applications in Metal Processing

The unique characteristics of induction heating make the coreless furnace ideal for several critical tasks in a foundry or metallurgical plant.

Melting and Superheating

This is the furnace's primary role. It can melt anything from ferrous metals like iron and steel to non-ferrous metals like copper, aluminum, and precious metals. After melting, the furnace can efficiently add more energy to superheat the liquid metal to the precise temperature required for casting.

Alloying and Composition Control

The electromagnetic field that melts the metal also creates a natural stirring action within the molten bath. This inductive stirring ensures the melt is homogenous, which is crucial when creating specific alloys. It allows for the even distribution of alloying elements, resulting in a final product with consistent chemical composition and properties.

Holding Molten Metal

In many operations, the furnace also acts as a "holder." After a large batch is melted, it can be held at a precise pouring temperature. This allows a continuous casting or pouring process to draw from a ready supply of liquid metal, decoupling the melting rate from the production line's speed.

Understanding the Advantages and Trade-offs

No technology is perfect for every scenario. Choosing a coreless induction furnace involves understanding its distinct benefits and limitations.

Advantage: Metallurgical Purity

Because the heat is generated directly within the metal, there are no by-products of combustion (like in a gas-fired furnace) to contaminate the melt. This results in a cleaner, higher-quality final metal, which is critical for demanding applications like aerospace or medical components.

Advantage: High Thermal Efficiency and Speed

Energy is transferred directly to the charge material with minimal heat loss to the surrounding environment. This makes the process highly efficient. Furthermore, coreless furnaces have very fast startup times and can achieve high melting rates.

Advantage: Flexibility

A coreless furnace can be completely emptied, cleaned, and used for a different alloy with minimal downtime. This makes it highly flexible for foundries that produce a variety of different metals and alloys, unlike channel furnaces which must maintain a molten heel.

Trade-off: Dependence on Charge Condition

The efficiency of a coreless induction furnace can be affected by the physical nature of the charge material. Very fine, loose, or heavily oxidized scrap may not couple as effectively with the magnetic field, potentially leading to lower efficiency and longer melt times.

Trade-off: Refractory Wear

The intense heat and electromagnetic stirring action place significant stress on the refractory lining of the crucible. This lining is a consumable item that requires regular monitoring and periodic replacement, which represents a key operational cost.

Making the Right Choice for Your Goal

Selecting the correct melting technology depends entirely on your operational priorities.

- If your primary focus is high-purity alloys and operational flexibility: The superior control and clean melting of a coreless induction furnace make it the ideal choice.

- If your primary focus is high-volume, continuous melting of a single ferrous metal: You may find a channel induction furnace or a cupola to be a cost-effective alternative, though you will sacrifice flexibility.

- If your primary focus is rapid cycling between different jobs and alloys: The ability to start, stop, and completely empty a coreless furnace gives it an unmatched advantage.

Ultimately, the coreless induction furnace empowers you to produce clean, homogenous, and precisely controlled molten metal on demand.

Summary Table:

| Application | Key Benefit |

|---|---|

| Melting & Superheating | Rapid, direct internal heating from solid to liquid state |

| Alloying & Composition Control | Natural inductive stirring ensures homogenous, consistent alloys |

| Holding Molten Metal | Maintains precise temperature for continuous casting operations |

| High-Purity Melting | No combustion contaminants; ideal for aerospace/medical grades |

Ready to achieve superior metallurgical control and flexibility in your foundry?

KINTEK's advanced coreless induction furnace solutions leverage our exceptional R&D and in-house manufacturing to deliver the clean, efficient melting you need. Whether you're working with ferrous metals, non-ferrous alloys, or precious metals, our furnaces provide the precise temperature control and homogenous stirring critical for high-quality results.

Our strong deep customization capability allows us to tailor the furnace system—including power supply, cooling, and controls—to your specific charge materials and production goals, helping you maximize efficiency and minimize refractory wear.

Contact KINTEL today to discuss how our coreless induction furnace technology can transform your metal thermal processing.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys