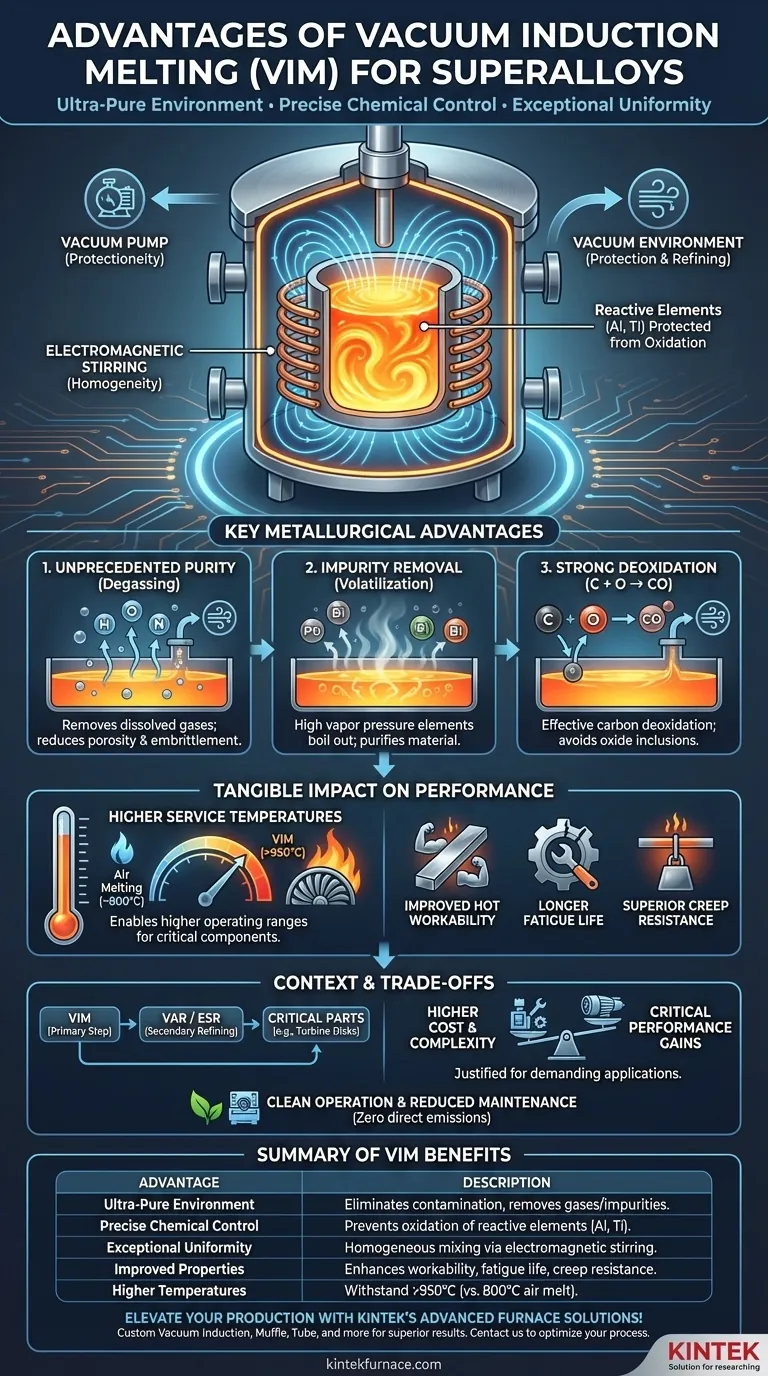

At its core, vacuum induction melting (VIM) provides three critical advantages for producing superalloys: an ultra-pure melting environment, precise chemical control over reactive elements, and exceptional compositional uniformity. This combination is what enables the creation of high-performance materials capable of withstanding extreme service conditions where conventional air-melted alloys would fail.

Vacuum induction melting is not merely a melting technique; it is a fundamental refining process. By creating a controlled vacuum, it eliminates the atmospheric contamination that degrades superalloys, allowing for the design and production of materials with superior strength, purity, and temperature resistance.

The Core Principle: A Controlled Melting Environment

The effectiveness of VIM technology stems from placing a standard induction furnace inside a sealed, evacuated chamber. This simple concept fundamentally changes the melting process from one of exposure to one of protection and refinement.

Why a Vacuum is Essential

Superalloys derive their incredible high-temperature strength from reactive elements, primarily aluminum (Al) and titanium (Ti). When melted in air, these vital elements rapidly oxidize, forming inclusions that compromise the alloy's integrity and mechanical properties.

The vacuum environment prevents this oxidation. By removing oxygen and nitrogen, VIM ensures these reactive elements remain in the metallic solution to perform their intended strengthening function.

How Induction Aids the Process

The induction furnace itself generates an electromagnetic field that heats and stirs the molten metal. This electromagnetic stirring is crucial, as it ensures all alloying additions are distributed perfectly evenly throughout the melt. The result is a completely homogeneous alloy with consistent properties from top to bottom.

Key Metallurgical Advantages

The controlled VIM environment delivers a series of distinct benefits that directly translate to higher quality superalloys.

Achieving Unprecedented Purity

The vacuum actively pulls dissolved gases like hydrogen, oxygen, and nitrogen out of the molten metal. This degassing process drastically reduces the potential for gas-related porosity and embrittlement, leading to a cleaner, more reliable final product.

Removing Harmful Impurities

Many detrimental trace elements, such as lead and bismuth, have a high vapor pressure. Under vacuum, these elements will literally boil out of the molten superalloy and are removed by the vacuum system. This volatilization effect is a powerful purification mechanism unique to vacuum processing.

Strong Deoxidation Capability

VIM facilitates a highly effective carbon deoxidation reaction. In the vacuum, carbon readily combines with any residual oxygen in the melt to form carbon monoxide (CO) gas, which is then pumped away. This is far more effective than using metallic deoxidizers, which can leave behind undesirable oxide inclusions.

Understanding the Trade-offs

While powerful, VIM is a specific tool with its own context. Understanding its role and limitations is key to using it effectively.

Often a Primary Melting Step

For the most demanding applications, like rotating jet engine components, VIM is the crucial first step in a multi-stage process. The "electrode" created by VIM is often remelted using secondary processes like Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR) to achieve even greater purity and an optimized grain structure.

Higher Complexity and Cost

Operating a vacuum furnace is inherently more complex and costly than air melting. The equipment, maintenance of vacuum systems, and longer cycle times contribute to a higher price point for VIM-produced materials. This cost is justified by the immense performance gains required for critical applications.

Environmental and Maintenance Benefits

Modern VIM furnaces are clean-operating systems with zero direct emissions, aligning with sustainability goals. Their designs, often incorporating distilled water cooling systems, also minimize maintenance by preventing scale buildup and ensuring high reliability.

The Tangible Impact on Superalloy Performance

The metallurgical advantages of VIM are not just theoretical; they produce dramatic improvements in the final material.

Enabling Higher Service Temperatures

By allowing for higher concentrations of reactive alloying elements and producing a cleaner base metal, vacuum smelting has been directly responsible for raising the capability of superalloys. For example, it increased the maximum service temperature of wrought superalloys from approximately 800°C to over 950°C.

Improving Mechanical Properties

The combination of high purity, low gas content, and chemical homogeneity leads to superior mechanical properties across the board. VIM-processed superalloys exhibit enhanced hot workability, longer fatigue life, and significantly improved creep resistance at high temperatures.

Making the Right Choice for Your Goal

- If your primary focus is producing critical rotating parts (e.g., turbine disks): VIM is the non-negotiable starting point to achieve the necessary purity and reliability.

- If your primary focus is developing new, advanced alloy compositions: VIM provides the pristine, controlled environment essential for accurate research and development.

- If your primary focus is improving the performance of an existing alloy: Transitioning from air-melt to VIM is one of the most effective ways to elevate its temperature capability and mechanical integrity.

Ultimately, vacuum induction melting is the cornerstone technology that makes modern jet engines, power turbines, and other high-performance systems possible.

Summary Table:

| Advantage | Description |

|---|---|

| Ultra-Pure Melting Environment | Eliminates atmospheric contamination, removes dissolved gases and impurities for cleaner alloys. |

| Precise Chemical Control | Prevents oxidation of reactive elements like Al and Ti, ensuring accurate alloy composition. |

| Exceptional Compositional Uniformity | Electromagnetic stirring provides homogeneous mixing for consistent properties throughout the melt. |

| Improved Mechanical Properties | Enhances hot workability, fatigue life, and creep resistance at high temperatures. |

| Higher Service Temperatures | Enables superalloys to withstand temperatures over 950°C, up from 800°C with air melting. |

Elevate your superalloy production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide vacuum induction furnaces and other systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, delivering superior purity, performance, and reliability. Contact us today to discuss how we can optimize your processes and achieve breakthrough results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications