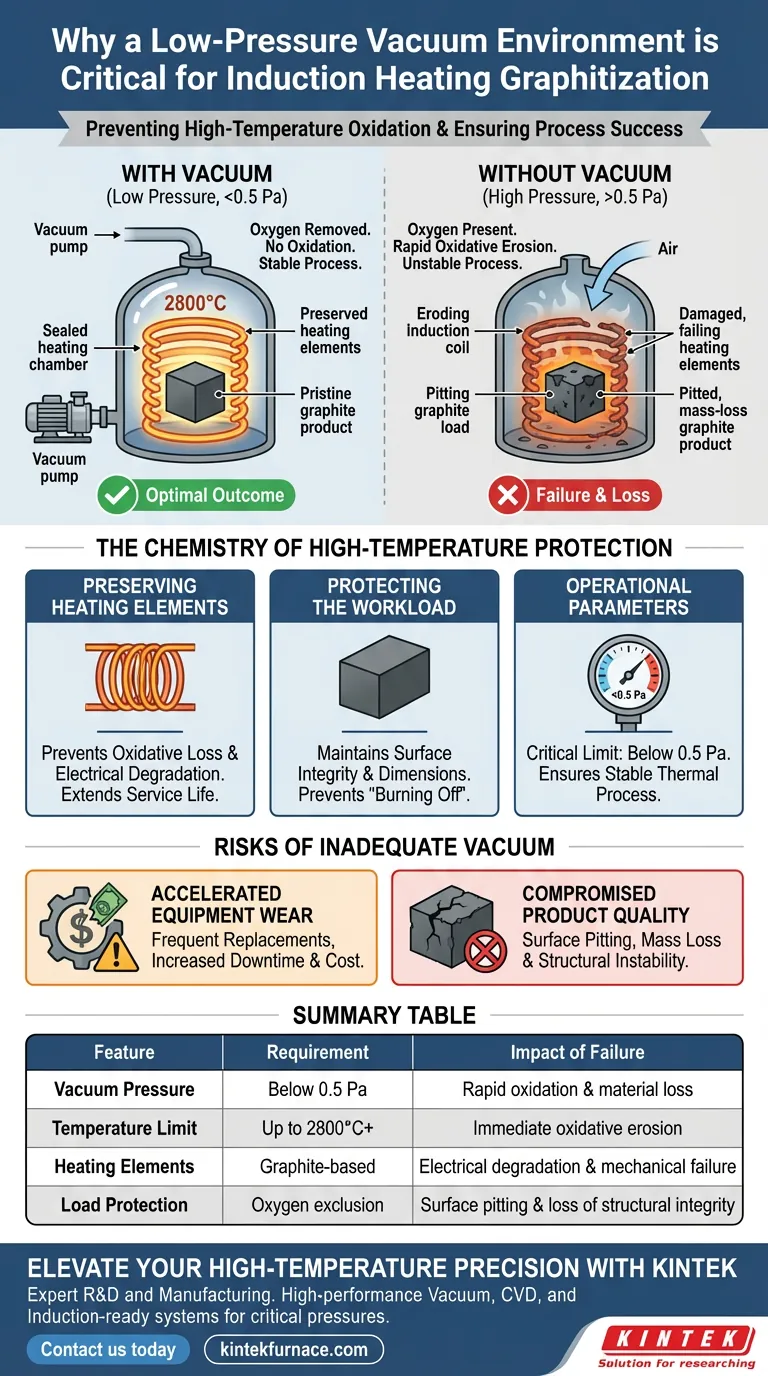

The critical necessity of a low-pressure vacuum environment during induction heating graphitization is dictated by the extreme chemical reactivity of carbon at high temperatures. Specifically, the vacuum is required to remove oxygen from the chamber, preventing the rapid destruction of both the heating elements and the graphite load through oxidation.

At process temperatures exceeding 2800°C, the presence of even trace amounts of oxygen leads to immediate oxidative erosion. Maintaining a vacuum below 0.5 Pa is the definitive safeguard that ensures material survival, process stability, and equipment longevity.

The Chemistry of High-Temperature Protection

The Oxidation Threshold

Graphitization requires extreme heat to realign carbon atoms into a crystalline structure. However, once temperatures rise, graphite becomes highly susceptible to reacting with oxygen.

Without a protective environment, the graphite does not just get hot; it chemically breaks down. The vacuum acts as a barrier, removing the air that would otherwise fuel this reaction.

Preserving Heating Elements

The induction furnace relies on graphite heating elements to generate the necessary thermal energy. These components are just as vulnerable as the product being treated.

If oxygen is present, these heating elements suffer from oxidative loss, effectively eroding away. This degradation alters the electrical properties of the elements and leads to premature mechanical failure.

Protecting the Workload

The graphite products (the load) undergoing graphitization must maintain their mass and structural integrity.

A vacuum environment ensures that the surface of the product remains pristine. By excluding air, you prevent the "burning off" of surface layers, ensuring the final product retains its intended dimensions and material properties.

Operational Parameters

The Critical Pressure Limit

To be effective, the vacuum must be substantial. The standard requirement for this process is maintaining a pressure typically below 0.5 Pa.

Operating above this pressure threshold introduces enough oxygen molecules to initiate significant erosion over the duration of the heating cycle.

Process Stability

A stable vacuum is synonymous with a stable thermal process.

Fluctuations in pressure can lead to inconsistent oxidation rates. By locking the pressure below 0.5 Pa, you ensure the thermal environment is controlled and predictable, allowing the induction heating mechanism to function without interference from chemical deterioration.

The Risks of Inadequate Vacuum Levels

Accelerated Equipment Wear

The most immediate trade-off of a poor vacuum is cost. If the system fails to maintain low pressure, the service life of the graphite heating elements is drastically shortened.

This forces frequent, expensive replacements and increases system downtime for maintenance.

Compromised Product Quality

Beyond equipment damage, a compromised vacuum affects the load. Inadequate air exclusion leads to surface pitting and mass loss in the graphite products.

This results in structural instability and potential rejection of the final components due to oxidative erosion.

Ensuring Process Success

To maximize the efficiency of your induction heating graphitization, consider these priorities:

- If your primary focus is Equipment Longevity: Ensure your vacuum pumps can reliably sustain pressures below 0.5 Pa to minimize the erosion rate of your heating elements.

- If your primary focus is Product Consistency: Monitor vacuum levels strictly throughout the cycle to prevent oxidative loss that alters the dimensions and quality of the graphite load.

Strict adherence to vacuum protocols is not merely an operational detail; it is the fundamental requirement for successful high-temperature graphitization.

Summary Table:

| Feature | Requirement | Impact of Failure |

|---|---|---|

| Vacuum Pressure | Below 0.5 Pa | Rapid oxidation and material loss |

| Temperature Limit | Up to 2800°C+ | Immediate oxidative erosion of carbon |

| Heating Elements | Graphite-based | Electrical degradation and mechanical failure |

| Load Protection | Oxygen exclusion | Surface pitting and loss of structural integrity |

Elevate Your High-Temperature Precision with KINTEK

Maintaining a flawless vacuum is the only way to safeguard your graphite assets and ensure product purity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, CVD, and induction-ready systems designed to sustain critical pressures below 0.5 Pa. Whether you need Muffle, Tube, or custom Rotary furnaces, our solutions are engineered for the extreme demands of graphitization.

Ready to optimize your thermal process? Contact us today to discover how our customizable lab and industrial furnaces can enhance your efficiency and equipment longevity.

Visual Guide

References

- Rui Li, Hongda Du. Design and Numerical Study of Induction-Heating Graphitization Furnace Based on Graphene Coils. DOI: 10.3390/app14062528

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Which industries commonly use IGBT induction melting furnaces? Unlock Precision & Efficiency

- What are the benefits of vacuum induction smelting technology? Achieve Superior Purity and Performance for Advanced Materials

- How are vacuum casting furnaces utilized in the medical industry? Ensure Purity and Precision for Medical Devices

- What are the primary functions of a Vacuum Induction Melting (VIM) furnace? Optimize Ni30 Superalloy Purity

- What role does a vacuum induction furnace play in Cu-Ni-P alloy melting? Achieving High-Purity Material Synthesis

- Why is an induction melting furnace useful with ultrasonic atomization? Achieve Superior Metal Powder Quality

- What is the best material for induction heating? Choose the Right Metal for Maximum Efficiency

- What role does a Vacuum Induction Melting furnace play in the production of high-aluminum nickel-based superalloys?