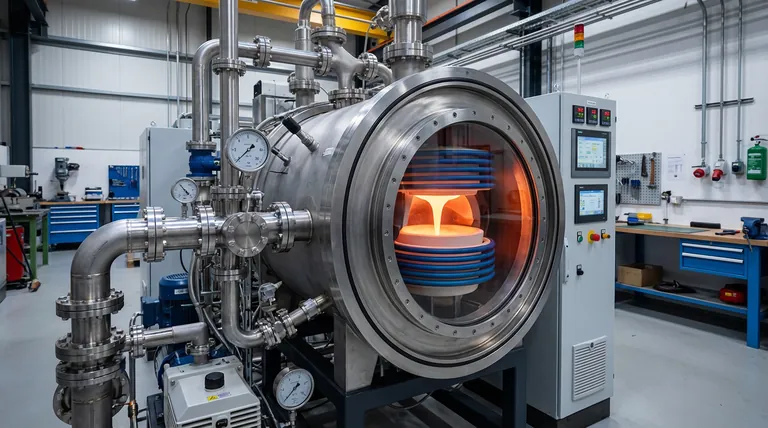

The primary role of a Vacuum Induction Melting (VIM) furnace is to create a controlled, oxygen-free environment that is critical for melting high-aluminum nickel-based superalloys. It prevents the rapid oxidation of reactive elements like aluminum, ensures the removal of impurity gases through degassing, and utilizes electromagnetic forces to homogenize the alloy's chemical composition.

Core Insight: The presence of oxygen is catastrophic for high-aluminum superalloys, as it depletes the aluminum necessary for strengthening the material. VIM technology solves this by strictly isolating the melt from the atmosphere, ensuring that the precise chemistry required for high-temperature creep resistance is maintained.

Preventing Oxidation and Impurities

The greatest challenge in producing high-aluminum superalloys is the high reactivity of the alloying elements. The VIM furnace addresses this through a specialized vacuum environment.

Protection of Active Elements

Aluminum (Al), along with Titanium (Ti) and Niobium (Nb), are "active" elements essential for the superalloy's performance.

In a standard furnace, these elements would react immediately with oxygen to form oxides (slag). The VIM furnace operates at low pressures (vacuum), effectively stopping this reaction and preventing the loss of these expensive and critical strengthening elements.

Vacuum Degassing

Beyond preventing new oxides from forming, the vacuum environment actively cleans the metal.

The low pressure facilitates vacuum degassing, a process where dissolved gases and volatile impurities are drawn out of the molten metal. This purification step is vital for avoiding defects that could compromise the structural integrity of the final component.

Ensuring Compositional Homogeneity

Nickel-based superalloys are complex "cocktails" of various metals. Achieving a uniform mixture is as important as the purity of the ingredients.

Electromagnetic Stirring

The "Induction" in Vacuum Induction Melting refers to the heating mechanism, which has a distinct secondary benefit: natural stirring.

The magnetic fields used to heat the metal generate strong electromagnetic forces within the melt. This causes the molten metal to circulate continuously, eliminating chemical segregation without the need for physical paddles or mixers that could introduce contaminants.

Uniformity of Trace Elements

This stirring action is particularly critical for distributing trace elements such as Boron (B) and Zirconium (Zr).

Even though these elements are added in minute quantities, they must be perfectly dispersed throughout the nickel matrix. The VIM process ensures that the chemical composition is consistent from the surface to the core of the ingot.

Understanding the Trade-offs

While VIM is the industry standard for superalloys, it requires rigorous process control to be effective.

Sensitivity to Process Parameters

The benefits of VIM are entirely dependent on maintaining specific vacuum levels (often as low as 0.01 hPa or 1.2–2.5 Pa).

If the vacuum seal is compromised or the pressure regulation fails, the melt can be instantly contaminated. Furthermore, while VIM ensures chemical purity, it is primarily a melting and refining tool; subsequent steps (like directional solidification) are often required to determine the final grain structure of the component.

Implications for Material Performance

The specific role of the VIM furnace translates directly to the mechanical properties of the final product.

- If your primary focus is High-Temperature Creep Resistance: The VIM process is non-negotiable, as it preserves the aluminum and titanium required to form the strengthening phases that resist deformation at 1520°C.

- If your primary focus is Material Cleanliness: The vacuum degassing capability serves as the primary defense against gaseous inclusions that lead to premature part failure.

By effectively controlling the atmosphere and mixing, the Vacuum Induction Melting furnace transforms volatile raw materials into aerospace-grade structural components.

Summary Table:

| Feature | Function in VIM | Impact on Superalloy |

|---|---|---|

| Vacuum Environment | Prevents Oxidation | Preserves active Al, Ti, and Nb elements |

| Degassing | Removes Dissolved Gases | Eliminates defects for structural integrity |

| Induction Heating | Electromagnetic Stirring | Ensures uniform chemical composition |

| Pressure Control | Volatile Removal | Purifies the melt of trace contaminants |

Elevate Your Superalloy Production with KINTEK

Precise control over vacuum levels and heating cycles is the difference between aerospace-grade components and material failure. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melting (VIM) systems, alongside our specialized Muffle, Tube, Rotary, and CVD furnaces.

Whether you need custom dimensions or specific vacuum thresholds for high-temperature superalloys, our systems are tailored to meet your unique metallurgical needs.

Ready to optimize your material purity? Contact our expert team today to discover how KINTEK’s advanced lab and industrial solutions can drive your innovation forward.

References

- Solidification and Casting of Metals and Alloys. DOI: 10.3390/met15010087

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What role does a vacuum non-consumable arc furnace play in high-entropy alloys? Master Complex Alloy Synthesis

- What are the benefits of induction furnace? Achieve Unmatched Efficiency & Purity in Metal Melting

- What are the different types of vacuum melting furnaces and how do they compare? Choose the Right Furnace for Your Metallurgical Needs

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What is the function of a vacuum arc melting furnace in Cobalt-based alloy prep? Achieve High Purity & Homogeneity

- What are the main components of a vacuum induction melting furnace (VIM furnace)? Discover the 5 Key Systems

- What role does a vacuum arc melting furnace play in the melting of Fe60Co15Ni15Cr10 alloys? Unlock Superior Uniformity

- What industries commonly use melt furnaces? Key Applications in Metal, Aerospace, and More