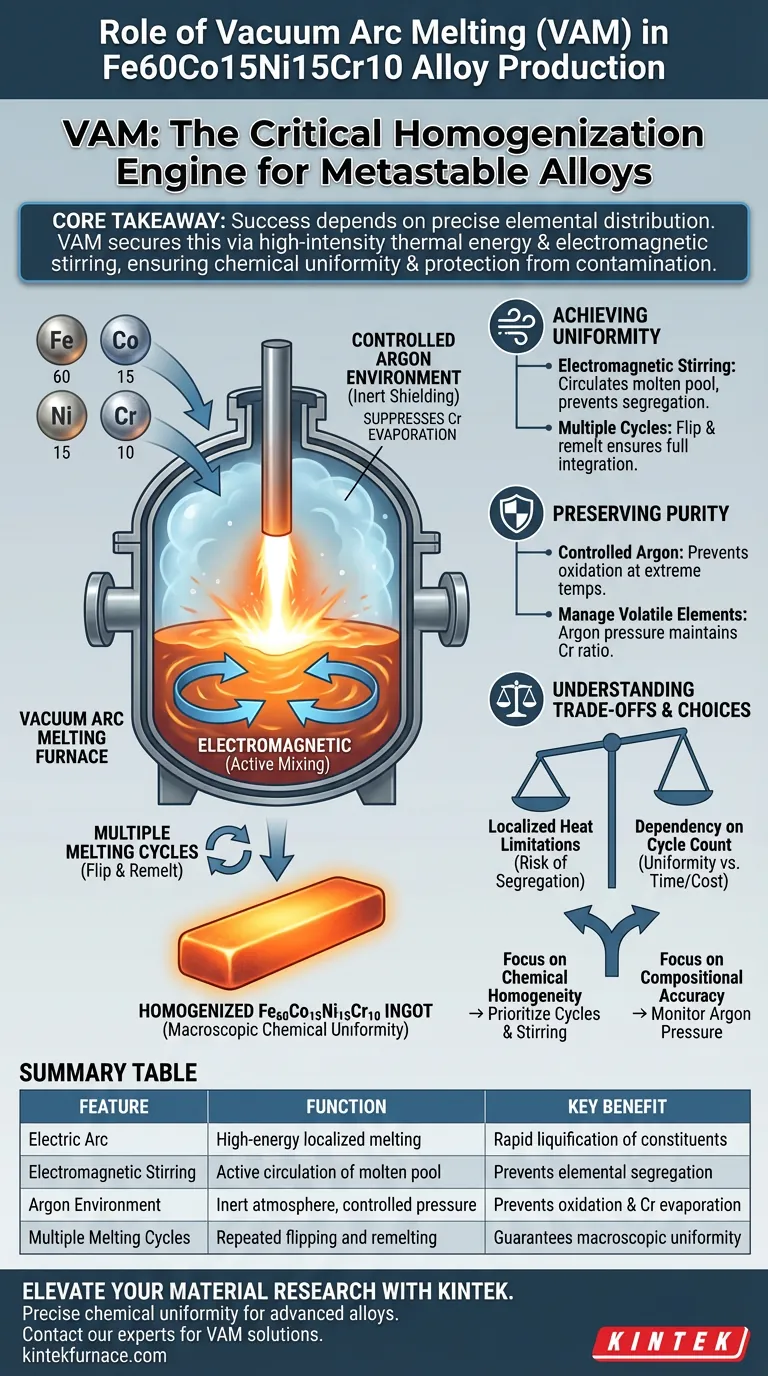

The vacuum arc melting furnace functions as the critical homogenization engine in the production of Fe60Co15Ni15Cr10 metastable alloys. By utilizing high-energy electric arcs within a controlled argon gas environment, it rapidly melts the constituent metals. The furnace employs electromagnetic stirring and multiple melting cycles to guarantee the macroscopic chemical uniformity required for subsequent microstructural control.

Core Takeaway The success of a metastable alloy depends entirely on precise elemental distribution. The vacuum arc melting furnace secures this by combining high-intensity thermal energy with electromagnetic stirring, ensuring the alloy achieves chemical uniformity while protecting it from oxidative contamination.

Achieving Macroscopic Chemical Uniformity

The primary challenge in creating Fe60Co15Ni15Cr10 alloys is ensuring that four distinct elements mix perfectly without segregating.

The Power of Electromagnetic Stirring

The furnace does not simply melt the metal; it actively mixes it. Primary reference data indicates the use of electromagnetic stirring during the melting process. This force circulates the molten pool, preventing heavier elements from settling and ensuring the iron, cobalt, nickel, and chromium are distributed evenly throughout the ingot.

The Necessity of Multiple Cycles

A single melt is rarely sufficient for complex multi-component alloys. To achieve true uniformity, the process employs multiple melting cycles. This often involves flipping the ingot between melts to ensure that material at the bottom of the water-cooled crucible is fully integrated into the bulk solution on subsequent passes.

Preserving Alloy Purity

Metastable alloys are sensitive to impurities, which can act as nucleation sites and destabilize the material structure.

Controlled Argon Environment

The melting process occurs within a controlled argon gas environment. This inert atmosphere is critical for preventing the oxidation of the metal components at extreme temperatures. By excluding oxygen, the furnace prevents the formation of oxide inclusions that would degrade the mechanical properties of the final alloy.

Managing Volatile Elements

While not explicitly detailed in the primary reference, the use of argon (pressure) rather than a hard vacuum is often strategic for alloys containing Chromium (Cr). Chromium has a high vapor pressure; a pure vacuum might cause it to evaporate. The argon atmosphere suppresses this evaporation, maintaining the precise stoichiometric ratio (Cr10) of the alloy.

Understanding the Trade-offs

While vacuum arc melting is the standard for high-purity ingots, it requires careful operational management.

Localized Heating Limitations

The electric arc generates intense, localized heat rather than heating the entire crucible uniformly at once. If the electromagnetic stirring is insufficient or the melting time is too short, localized chemical segregation can occur. This creates "unmelted" or element-rich zones that ruin the macroscopic uniformity.

Dependency on Cycle Count

Achieving the "high degree of chemical uniformity" mentioned in the primary reference is not automatic. It is directly dependent on the number of remelting cycles performed. Insufficient cycling leads to inhomogeneity, while excessive cycling increases energy costs and process time without yielding significant marginal gains.

Making the Right Choice for Your Goal

When configuring your melting process for Fe60Co15Ni15Cr10, prioritize your parameters based on the desired outcome.

- If your primary focus is Chemical Homogeneity: Prioritize the number of melting cycles and ensure electromagnetic stirring is active to eliminate macroscopic segregation.

- If your primary focus is Compositional Accuracy: Monitor the argon pressure carefully to prevent the oxidative loss of active elements or the evaporation of Chromium.

Ultimately, the vacuum arc melting furnace serves not just as a heater, but as a precision mixing vessel that establishes the chemical foundation necessary for advanced microstructural manipulation.

Summary Table:

| Feature | Function in Fe60Co15Ni15Cr10 Melting | Key Benefit |

|---|---|---|

| Electric Arc | High-energy localized melting of constituent metals | Rapid liquification of Cr, Ni, Co, Fe |

| Electromagnetic Stirring | Active circulation of the molten pool | Prevents elemental segregation |

| Argon Environment | Inert atmosphere at controlled pressure | Prevents oxidation and Cr evaporation |

| Multiple Melting Cycles | Repeated flipping and remelting of the ingot | Guarantees macroscopic chemical uniformity |

Elevate Your Material Research with KINTEK

Precise chemical uniformity is the backbone of high-performance metastable alloys. At KINTEK, we provide the advanced thermal technology required to achieve perfect elemental distribution.

Backed by expert R&D and manufacturing, KINTEK offers Vacuum Arc Melting systems, Muffle, Tube, Rotary, and CVD furnaces, all customizable to meet your specific research or production needs. Whether you are working with complex Fe-based alloys or high-vapor-pressure elements, our systems deliver the controlled environments and stirring precision your lab demands.

Ready to optimize your alloy homogeneity? Contact our experts today to find the perfect high-temperature solution for your unique needs.

Visual Guide

References

- Yemao Lu, Yulia Ivanisenko. Overcoming plasticity reduction in a severely deformed nano-grained metastable alloy. DOI: 10.1080/21663831.2024.2356761

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What technical advantages does a Vacuum Arc Melting Furnace provide? Master Sulfur-Doped Copper Alloy Purity

- How does high thermal efficiency benefit induction furnaces? Unlock Major Cost Savings & Quality

- What makes induction furnaces suitable for precious metals processing? Unlock Purity and Efficiency in Metal Melting

- What is the function of a non-consumable vacuum arc melting furnace? Synthesizing Ultra-Pure Zr2Fe-based Alloys

- What is vacuum casting and how does it differ from conventional casting? Ideal for Low-Volume, High-Detail Prototyping

- What industries primarily use vacuum induction melting furnaces? Essential for High-Performance Alloys

- What is the role of a vacuum induction furnace in CuNiSiCrCoTiNbx synthesis? Ensure Purity & Homogeneity

- How does an integrated system of in-situ neutron diffraction, high-frequency induction heating, and deformation devices address technical challenges in metallurgical research? Uncover Real-Time Microstructural Evolution