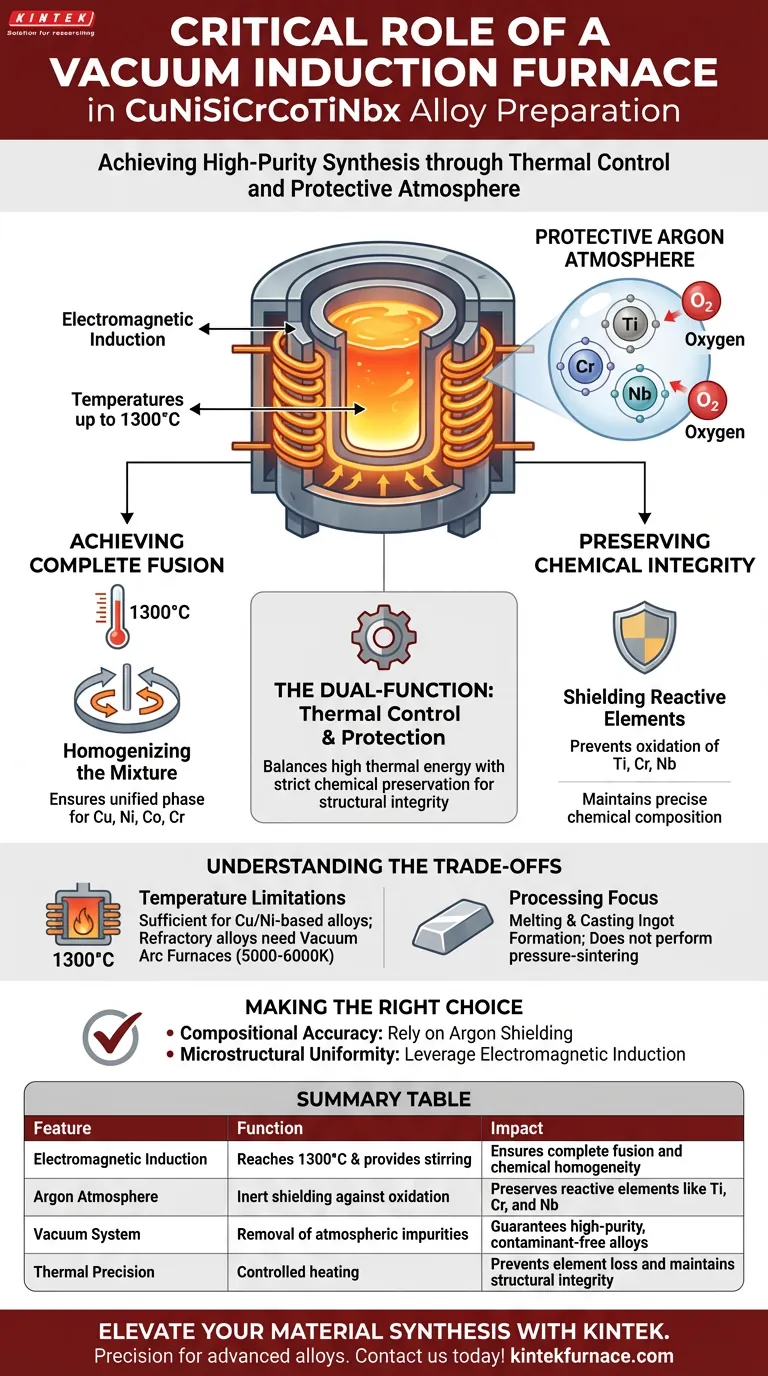

The vacuum induction furnace serves as the critical synthesis tool for the preparation of CuNiSiCrCoTiNbx medium-entropy alloys. It functions by utilizing electromagnetic induction to generate temperatures up to 1300°C, ensuring the complete fusion of the base metals while simultaneously maintaining a protective argon atmosphere to prevent the degradation of reactive alloying elements.

Core Takeaway The preparation of medium-entropy alloys requires a delicate balance between high thermal energy and strict chemical preservation. The vacuum induction furnace solves this by providing the necessary heat to fuse complex elements while shielding reactive components like Titanium and Niobium from oxidation, thereby guaranteeing the alloy's structural integrity and precise chemical composition.

The Dual-Function of Thermal Control and Protection

To understand the necessity of this equipment, one must look at the specific requirements of the CuNiSiCrCoTiNbx alloy system. The furnace addresses two distinct challenges: achieving a homogeneous melt and preventing chemical contamination.

Achieving Complete Fusion

The primary function of the furnace is to create a high-temperature environment capable of melting diverse metallic elements.

Reaching Thermal Thresholds The furnace utilizes electromagnetic induction to reach temperatures as high as 1300°C.

This thermal capacity is essential for ensuring that base elements—specifically Copper (Cu), Nickel (Ni), Cobalt (Co), and Chromium (Cr)—are brought to a fully molten state. Without reaching this specific temperature tier, the alloy cannot achieve a unified phase.

Homogenizing the Mixture While high temperature melts the metal, the induction mechanism plays a secondary, critical role.

The electromagnetic field naturally induces a stirring effect within the molten metal. This ensures that the various elements are thoroughly mixed, creating a chemically homogeneous alloy rather than a stratified mixture of independent metals.

Preserving Chemical Integrity

The presence of reactive elements in the CuNiSiCrCoTiNbx formula makes standard open-air melting impossible.

Shielding Reactive Elements The alloy includes Titanium (Ti), Chromium (Cr), and Niobium (Nb), which are classified as active alloying elements.

These metals have a high affinity for oxygen and will rapidly oxidize if exposed to air at melting temperatures. Oxidation alters the chemical composition and introduces impurities that can ruin the alloy's properties.

The Role of the Argon Atmosphere To counter oxidation, the furnace operates with a vacuum system that is backfilled with a protective argon atmosphere.

This inert gas creates a barrier around the melt. It effectively prevents the active elements from reacting with the environment, ensuring the final product maintains the precise chemical composition intended by the design.

Understanding the Trade-offs

While the vacuum induction furnace is ideal for this specific class of medium-entropy alloys, it is important to recognize its operational boundaries compared to other synthesis methods.

Temperature Limitations

The 1300°C capability is sufficient for Cu-based and Ni-based medium-entropy alloys.

However, it falls short for refractory high-entropy alloys (such as those containing Tungsten or Tantalum), which often require Vacuum Arc Furnaces capable of reaching 5000–6000 K. You must ensure your alloy's melting point does not exceed the furnace's inductive limit.

Processing Focus

This furnace is designed primarily for melting and casting (ingot formation).

It does not perform the simultaneous pressure-and-sintering functions of a Vacuum Hot Press. If your goal is to consolidate powders directly into a dense shape without a full melting phase, an induction furnace is not the correct tool.

Making the Right Choice for Your Goal

The vacuum induction furnace is not a universal tool, but it is the standard for high-purity melting of this specific alloy class.

- If your primary focus is Compositional Accuracy: Rely on the argon shielding to prevent the loss of Titanium and Niobium to oxidation.

- If your primary focus is Microstructural Uniformity: Leverage the electromagnetic induction capabilities to ensure thorough mixing of elements like Nickel and Cobalt.

By controlling both the temperature and the atmosphere, the vacuum induction furnace transforms a complex mixture of raw metals into a precise, high-purity engineering material.

Summary Table:

| Feature | Function in Alloy Preparation | Impact on Quality |

|---|---|---|

| Electromagnetic Induction | Reaches 1300°C & provides stirring | Ensures complete fusion and chemical homogeneity |

| Argon Atmosphere | Inert shielding against oxidation | Preserves reactive elements like Ti, Cr, and Nb |

| Vacuum System | Removal of atmospheric impurities | Guarantees high-purity, contaminant-free alloys |

| Thermal Precision | Controlled heating for specific alloy systems | Prevents element loss and maintains structural integrity |

Elevate Your Material Synthesis with KINTEK

Precision is paramount when developing advanced medium-entropy alloys like CuNiSiCrCoTiNbx. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum, induction, and CVD systems tailored for the most demanding lab requirements. Whether you need standard high-temperature furnaces or fully customizable solutions for unique material research, our engineering team is ready to support your innovation.

Ready to achieve superior chemical integrity? Contact us today to find the perfect furnace for your lab!

Visual Guide

References

- Denis Ariel Ávila-Salgado, José Luis Camacho-Martínez. Evolution of Microstructure, Hardness, and Wear Behavior of Medium-Entropy CuNiSiCrCoTiNbx Alloy. DOI: 10.3390/lubricants13040164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a high-purity argon environment required during iron melting? Ensure Precise Steel Oxide Inclusion Simulation

- What are the advantages of vacuum induction melting and casting (VIM&C) over VIM? Achieve Superior Metallurgical Quality and Efficiency

- What is the function of a vacuum arc melting furnace in Cobalt-based alloy prep? Achieve High Purity & Homogeneity

- What are the technical advantages of using a Vacuum Induction Melting furnace in the development of advanced packaging steel?

- What is the critical function of a vacuum induction furnace in the preparation of Fe-Cu-Nb-Mo-Si-B master alloys?

- What are the differences between induction-heated and resistance-heated vacuum furnaces? Choose the Right Heating Method for Your Lab

- What types of materials can be smelted in an induction furnace? Master the Art of Clean, Efficient Metal Melting

- What are the fundamental principles behind induction heating? Unlock Efficient, Non-Contact Heat for Your Lab